Multi-component ground coating, toning method, and coating repairing method

A coating and metal coating technology, applied in the field of repairing coatings, can solve the problems of reducing coating VOC, suppressing unevenness, and worsening work efficiency, achieving good coating workability and finishing, and reducing the number of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0128] Hereafter, although an Example demonstrates this invention more concretely, this invention is not limited to these Examples. In addition, "parts" and "%" in the following examples represent "parts by mass" and "% by mass", respectively.

[0129]

manufacture example 1

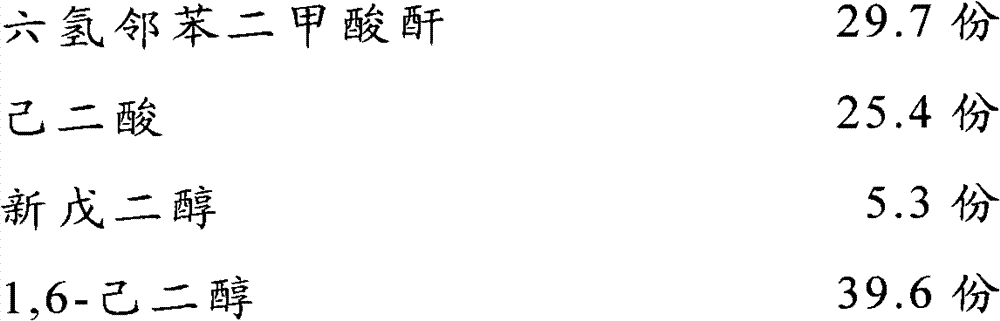

[0131] Add the following components to a reactor with a capacity of 4 liters equipped with a heating device, a thermometer, a stirrer, a rectification column, and a reflux condenser with a water separator, heat at 160°C, and spend 3 hours to raise the temperature from 160°C to 230°C ℃.

[0132]

[0133] This was maintained at 230° C. for 1 hour, and generated condensed water (7.4 parts) was distilled off using a rectification column. Next, 5 parts of xylene was added, xylene and condensation water were refluxed, and water was removed using a water separator. Two hours after the addition of xylene, the measurement of the acid value was started, and when the acid value became 2 mgKOH / g or less, the pressure was reduced, and xylene was almost completely distilled off. Thereafter, it was cooled to 120° C., diluted with butyl acetate so that the solid content was 70%, and a butyl acetate solution of a polyester resin having a weight average molecular weight of 20,000 and a resi...

manufacture example 2

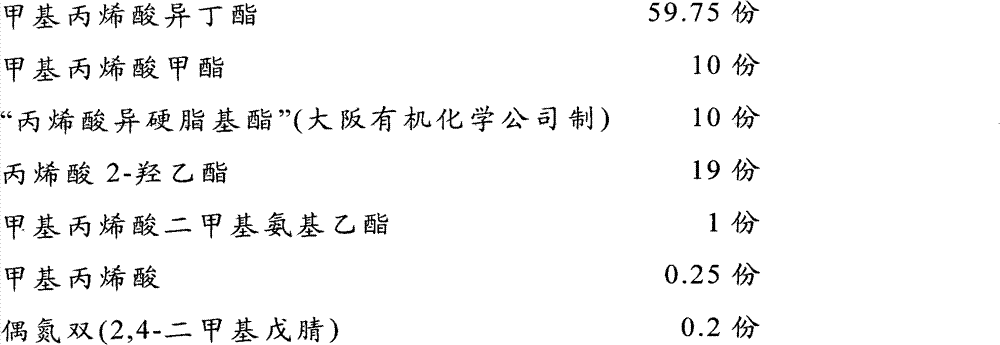

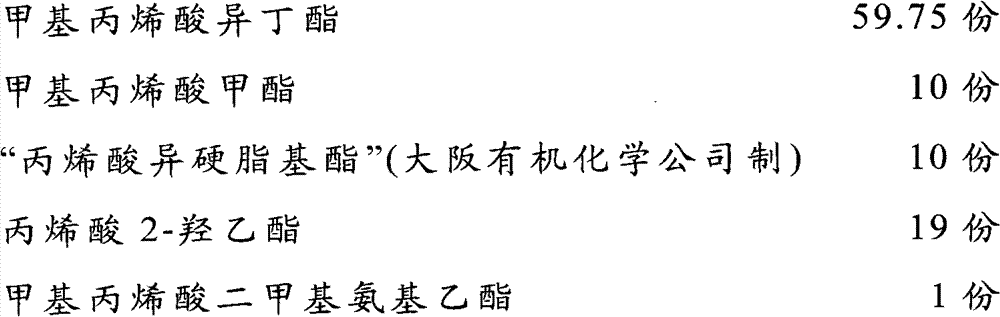

[0136] Add 68 parts of butyl acetate to a reactor with a capacity of 4 liters equipped with a thermometer, a stirrer, a reflux condenser, and a dropping pump, raise the temperature to 110°C while stirring, and drop it at a constant rate for about 3 hours at 110°C. A mixed solution of the following monomer mixture and polymerization initiator was added.

[0137]

[0138] After the dropwise addition was completed, the temperature was kept at 110°C for 1 hour, and the stirring was continued. After that, 0.5 parts of azobisdimethylvaleronitrile dissolved in 14 parts of butyl acetate was added dropwise at a constant speed for 1 hour as an additional catalyst. Then, after the dropwise addition, it was kept at 110° C. for 1 hour, the reaction was terminated, and diluted with butyl acetate to obtain an acrylic resin solution (A -1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com