Dust returning method for fluidized bed, and fluidized bed gasifier based on same

A technology of fluidized bed gasification furnace and gasification furnace, which is applied in the field of coal gasification, can solve the problems of difficult combustion and gasification, and reduce the reaction efficiency of gasification furnace, so as to achieve the effect of increasing the speed and improving the efficiency of coal gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

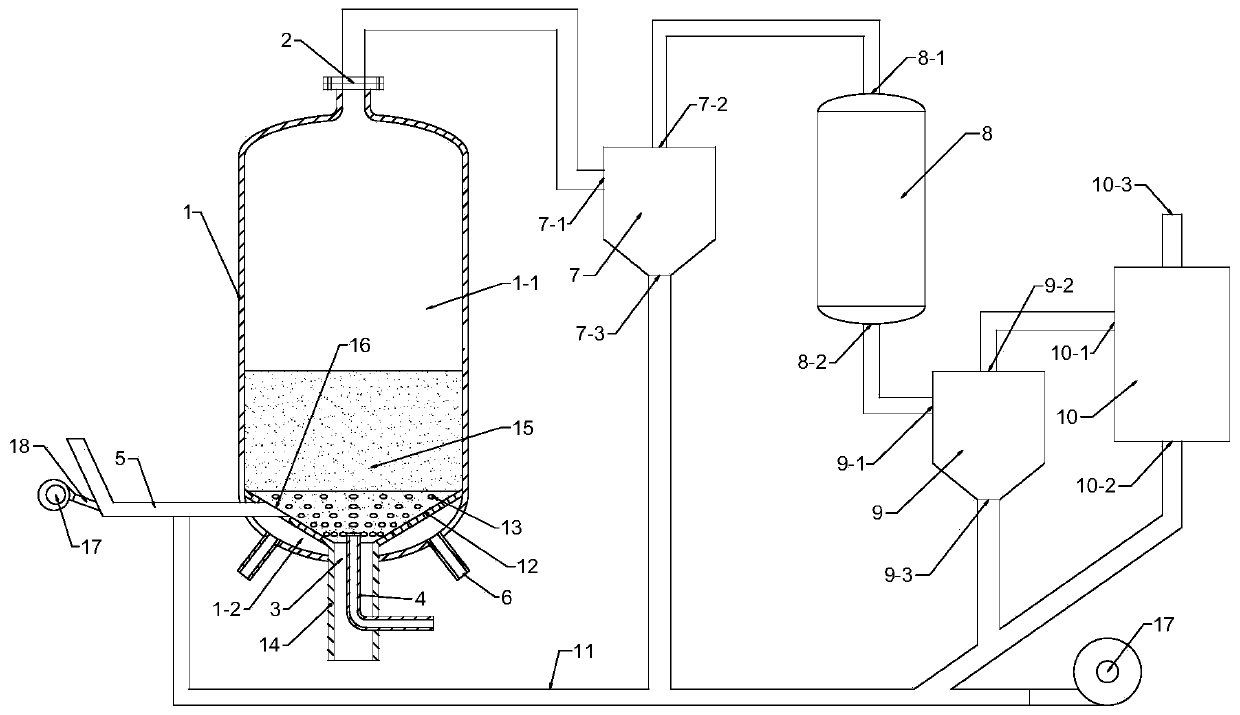

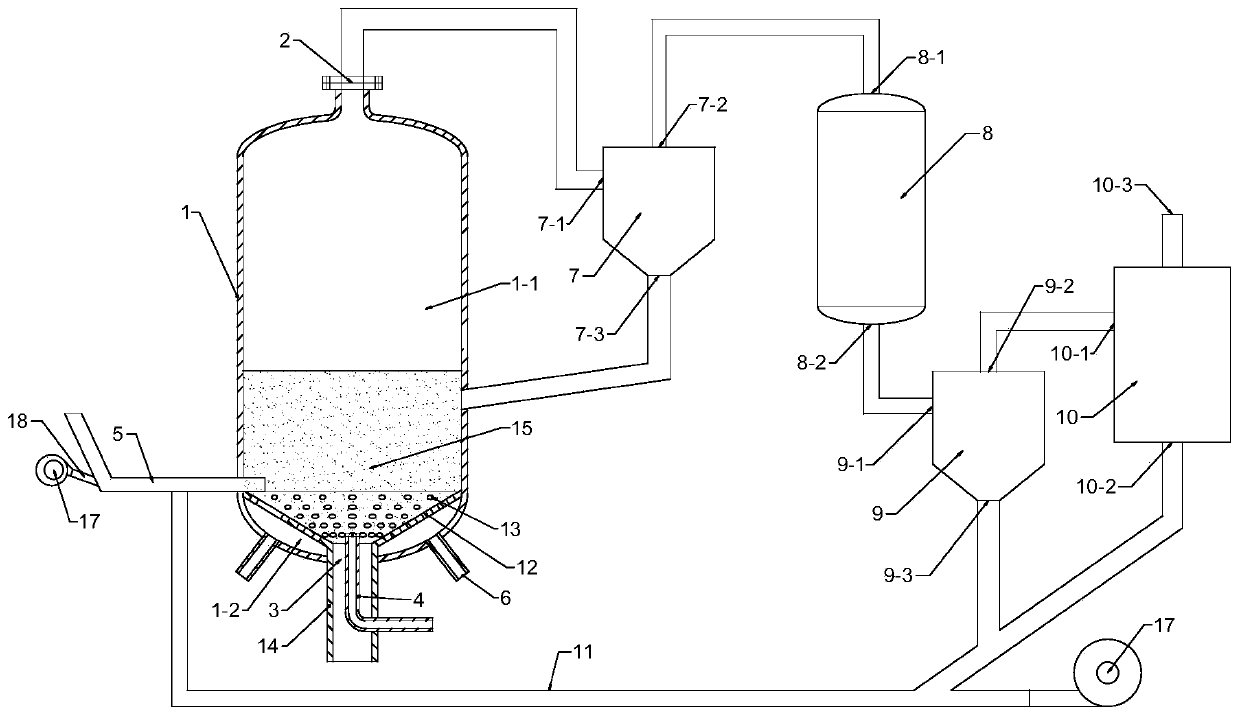

[0042] refer to figure 2 , the powder returning method of the fluidized bed described in the present embodiment comprises the following specific steps:

[0043] a. Carry out at least one gas-solid separation on the gas with fly ash generated by the fluidized bed gasifier to collect the fly ash and obtain pure gas;

[0044] b. Collect the fly ash separated from step a, mix it with raw coal, and send it into the gasifier for combustion and coal gasification reaction.

[0045] In this embodiment, the gas with fly ash generated by the fluidized bed gasifier is subjected to multiple gas-solid separations, and waste heat recovery is performed on the gas with fly ash between times of gas-solid separation, and then after the waste heat is recovered, the The low-temperature fly ash produced by gas-solid separation is collected and mixed with raw coal, and then sent to the gasifier for combustion and coal gasification reaction, while the high-temperature fly ash produced by gas-solid ...

Embodiment 3

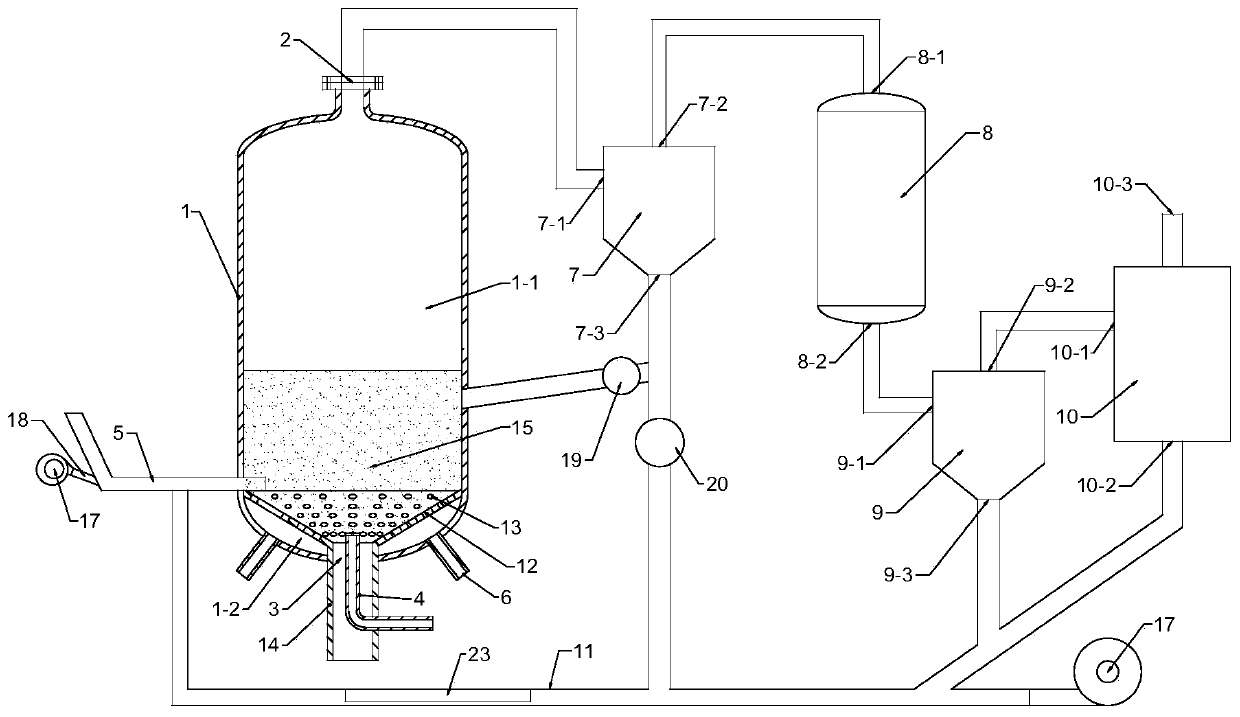

[0050] This embodiment has been further improved on the basis of embodiments 1 and 2. The specific structure is similar to that of embodiment 2. The difference is that in this embodiment, the ash discharge port A communicates with the powder return pipeline 11 through a main pipe 21, while A branch pipe 22 is connected to the main pipe 21 to directly communicate with the cylinder body 1. The branch pipe 22 is provided with a first valve 19, and the main pipe 21 between the branch pipe and the powder return pipeline 11 is provided with a second valve 20, so that Switch the opening and closing of the first valve 19 and the second valve 20 to switch whether the fly ash discharged from the ash outlet A enters the coal inlet pipe 5 through the powder return pipe 11 or directly enters the cylinder 1 through the branch pipe 22 . The first valve 19 and the second valve 20 are powder regulating valves with cooling function.

[0051] In order to facilitate the statistics of the amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com