An integral lightweight gear shaft and its manufacturing process

A gear shaft, lightweight technology, applied in belts/chains/gears, shafts, shafts and bearings, etc., can solve problems such as high cost, low production efficiency, and inability to guarantee performance, and achieve high production efficiency, light weight, and improved The effect of material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to illustrate the technical solution of the present invention more clearly, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

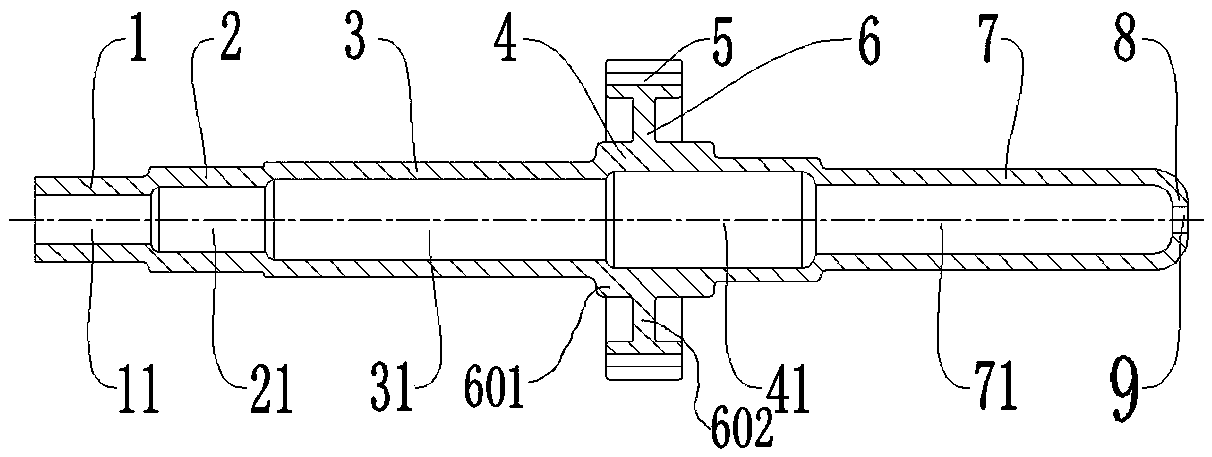

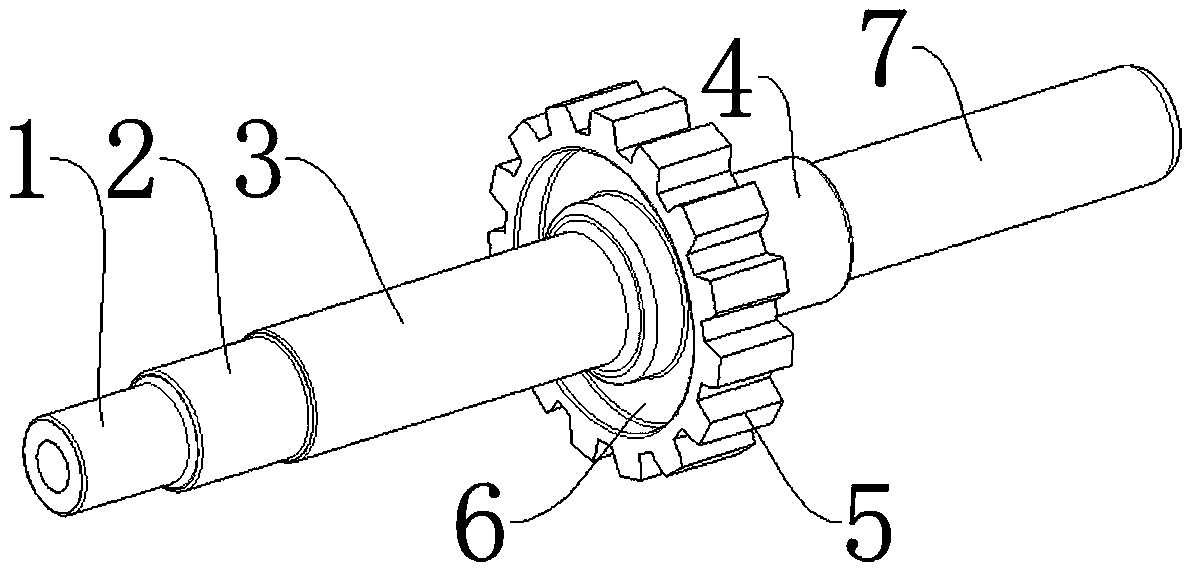

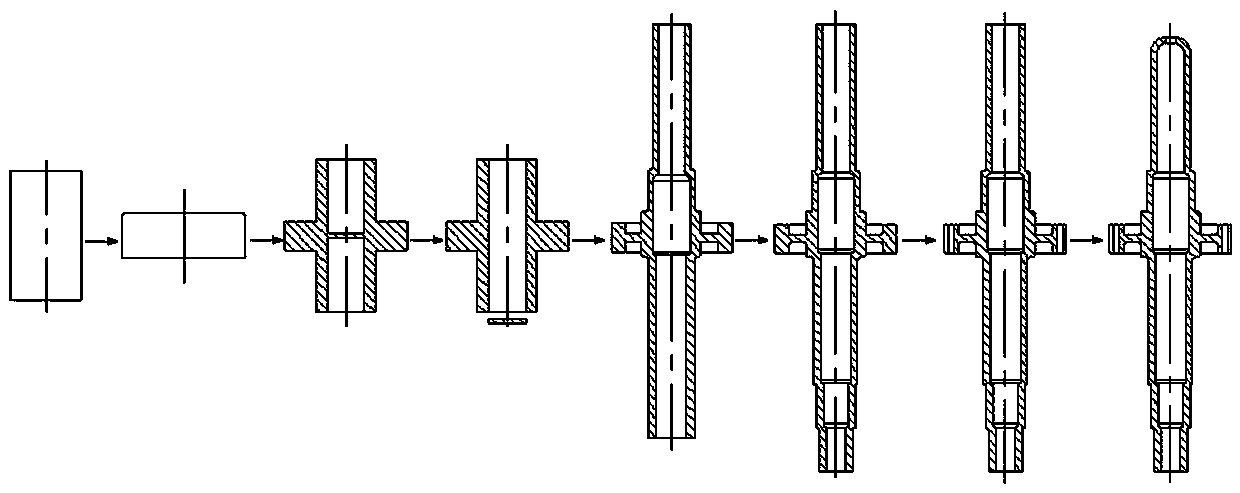

[0034] Such as figure 1 , figure 2As shown, an integral lightweight gear shaft, the gear shaft includes a central shaft part and a gear plate part, and the central shaft part includes a first shaft section 1, a second shaft section 2, a third shaft section 3, and a fourth shaft section 4 And the fifth shaft segment 7, the gear disc part includes a gear disc 6 and a plurality of gear teeth 5 evenly arranged on the outer circumference of the gear disc 6, the gear disc part is symmetrically arranged on the outside of the fourth shaft segment 4, and the center of the central shaft part The line coincides with the center line of the gear disc part, and the gear disc 6 is composed of an inner ring 601 and an outer ring 602, wherein the inner ring 601 fits...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com