An intelligent temperature control device for eccentric body tiles of a mechanical press

A technology of a mechanical press and a temperature control device, which is applied in the field of mechanical presses, can solve the problems that the eccentric body tile cannot be cooled, accelerates wear, and the temperature of the eccentric body tile rises, so as to avoid rapid wear or damage safety accidents and improve Equipment precision, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

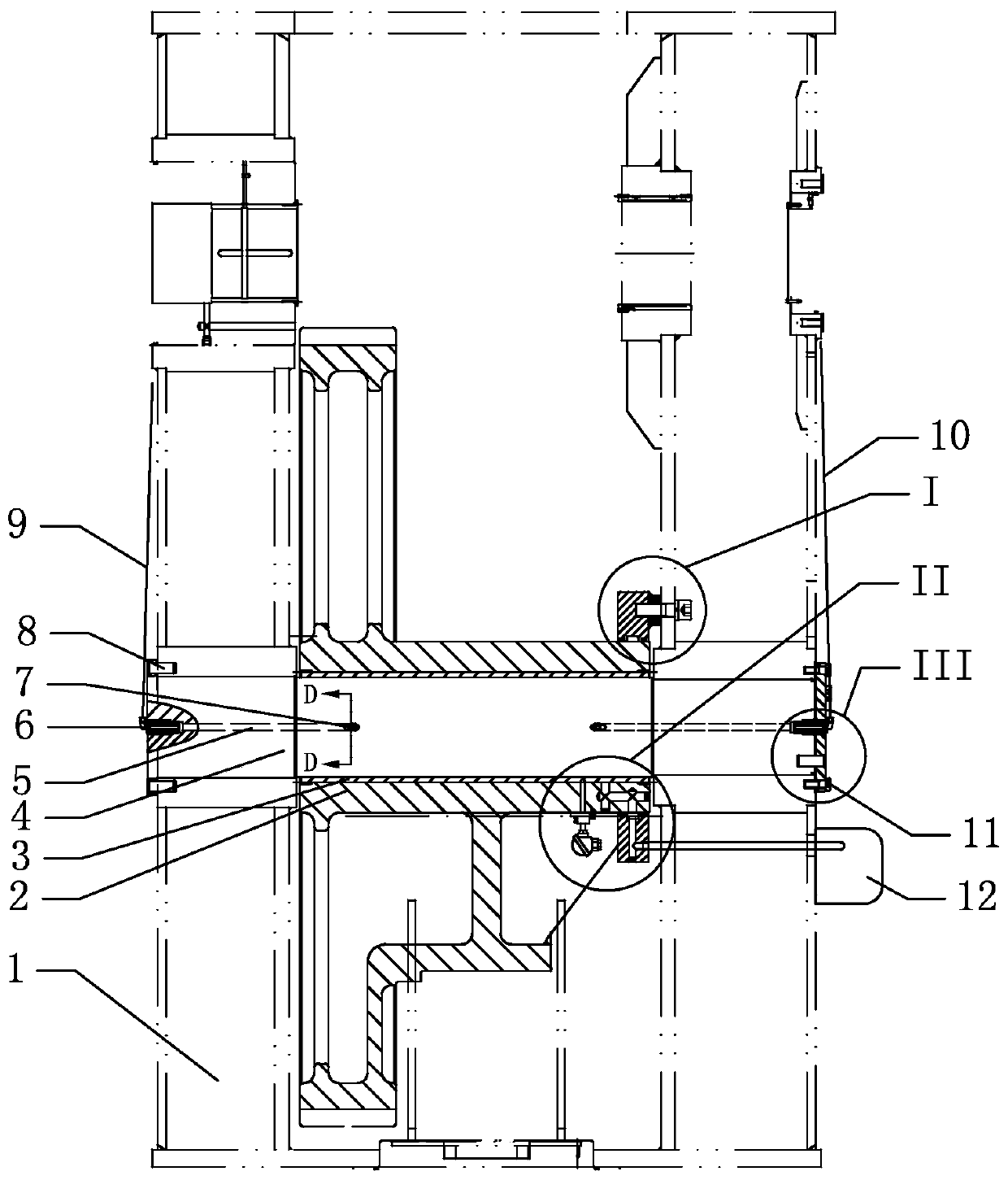

[0035] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation methods and in conjunction with the accompanying drawings.

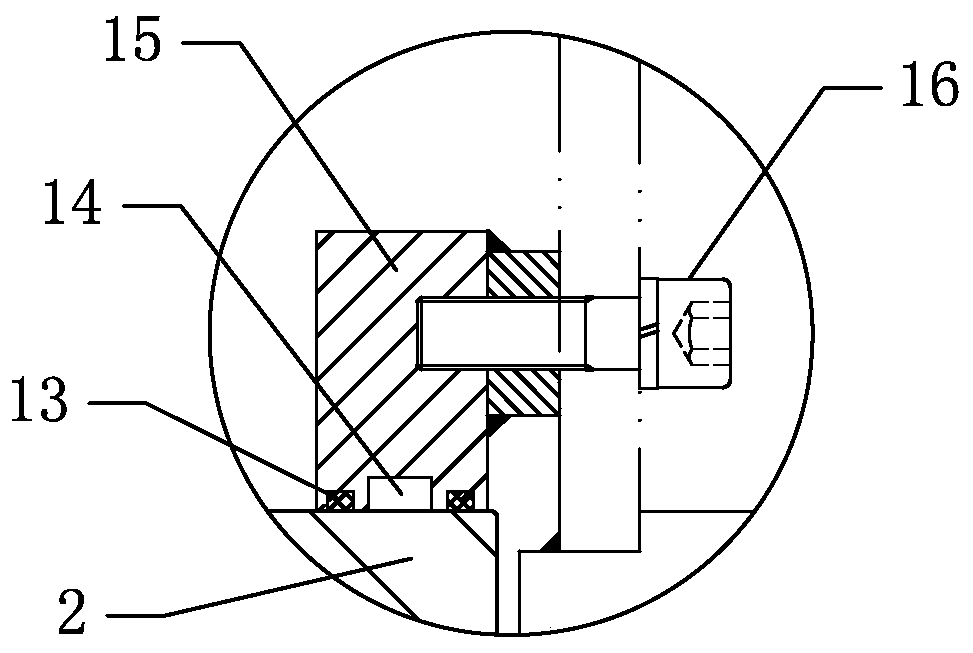

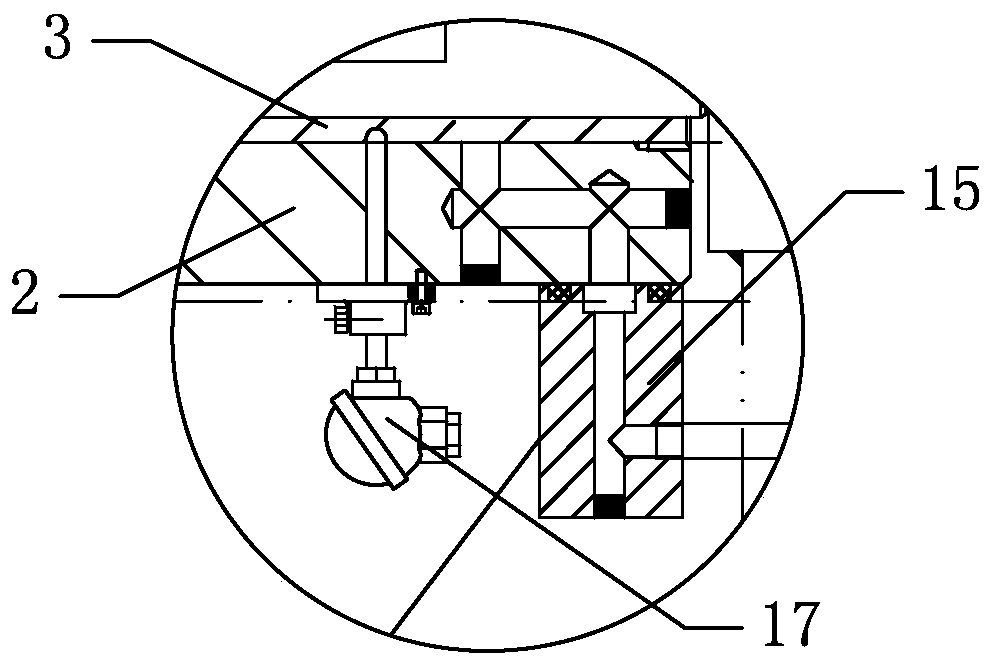

[0036] An intelligent temperature control device for an eccentric body tile of a mechanical press, comprising an eccentric body 2, the inner hole of the eccentric body 2 is sequentially installed with an eccentric body tile 3 and a mandrel 4, and one end of the mandrel 4 is provided with a pillow block, and passes through a cylinder The pin 8 is fixed on the upper beam 1, and the other end of the mandrel 4 is provided with an adjustment pad and an end cover, and the end cover and the adjustment pad are fixed on the mandrel 4 and the upper beam 1 by bolts and cylindrical pins 8. The above-mentioned bolts are hexagonal head bolts 11 with holes, and the hexagonal head bolts 11 with holes are used to prevent loosening through the iron wire 18. At the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com