An all-in-one machine for deburring and spraying of wiper arm motor cover

A technology for deburring and wiper arms, which is applied in the field of wiper arm motor cover deburring and spraying integrated machines, which can solve the problems of unusable holding fixtures, poor output, and inability to carry out automatic deburring work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments of the present invention will be further described in detail with reference to the following drawings and examples:

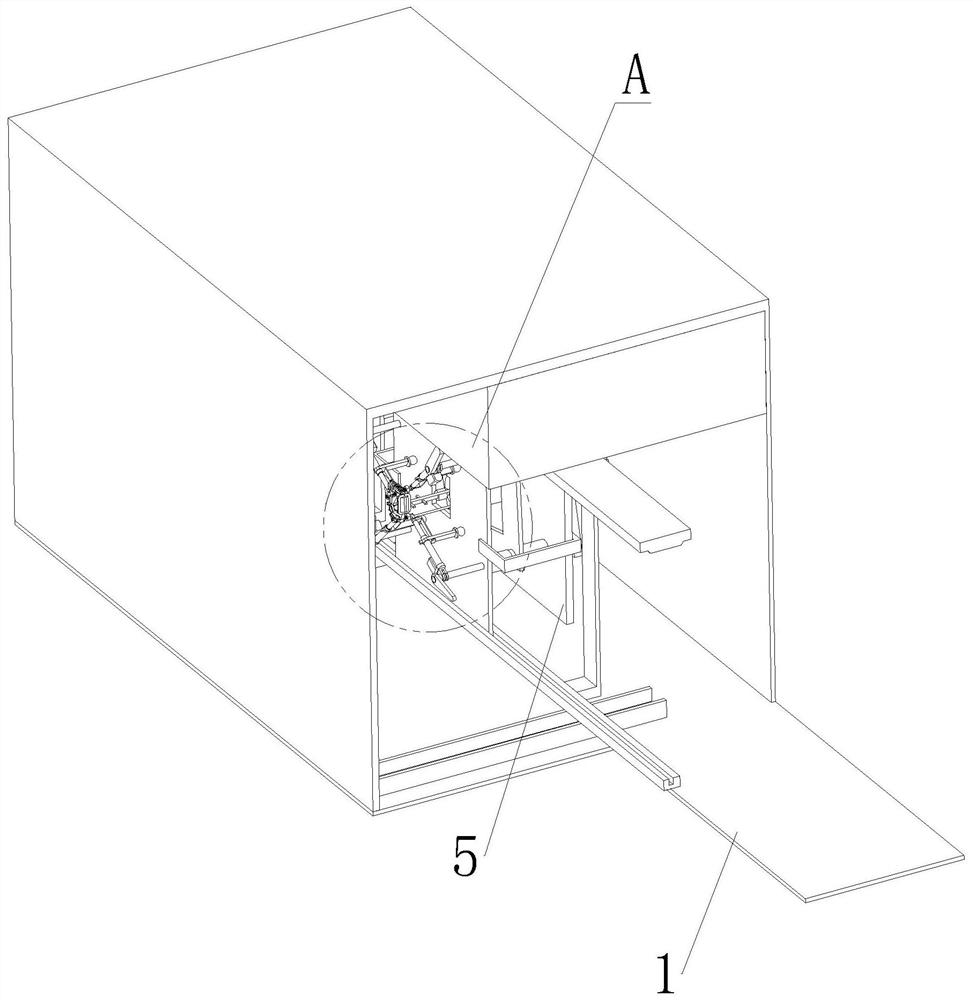

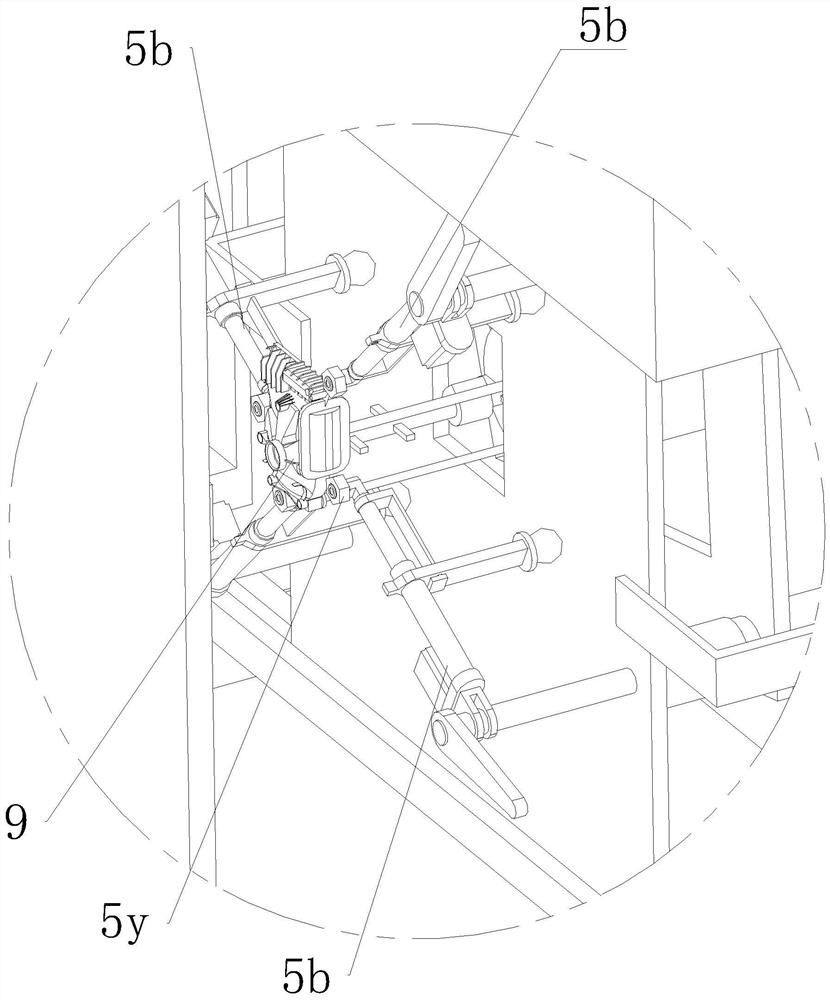

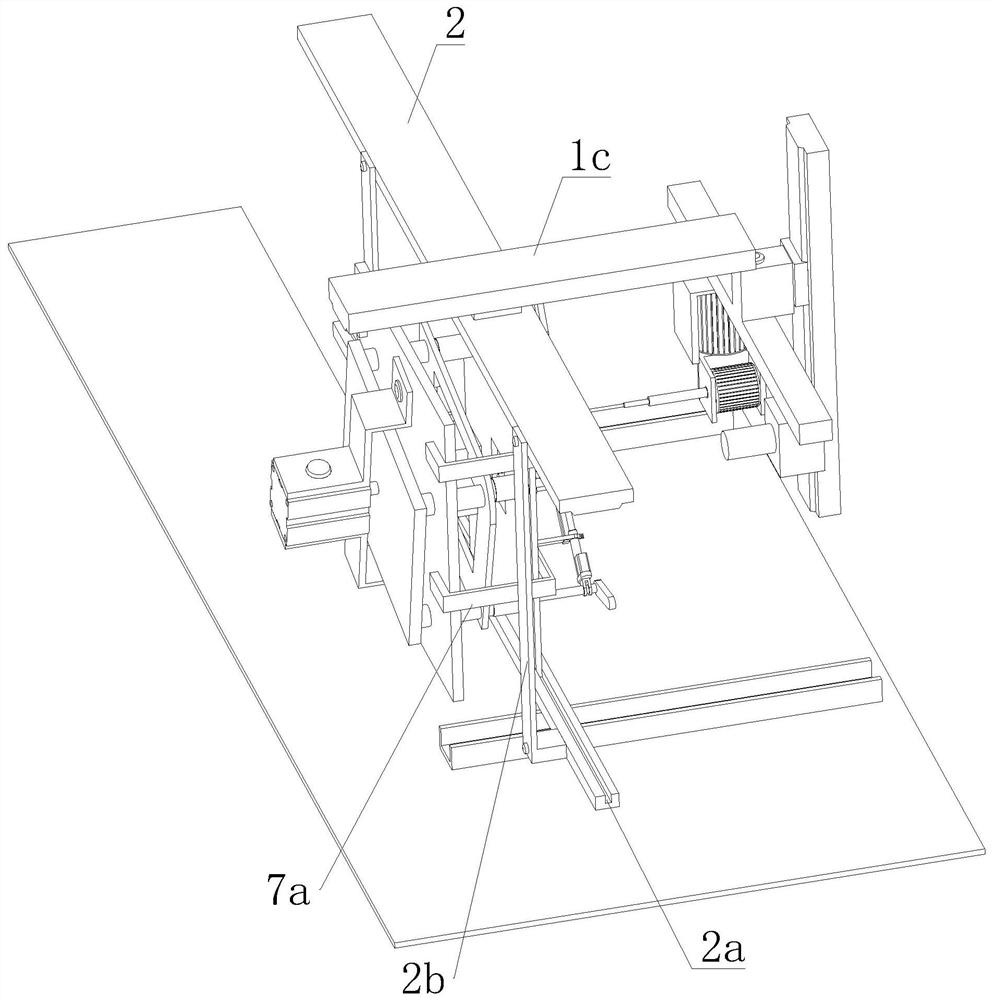

[0039] refer to 1 to 14 An all-in-one deburring and spraying machine for wiper arm motor cover is shown, which comprises a machine table 1, a feeding channel, a spraying device, a deburring device and a locking device for limiting the motor cover 9. The feeding channel is arranged at the top of the machine table 1 in parallel, and the locking device comprises a positioning plate 5 which can move horizontally in the feeding channel and at least four clamping poles 5b. The positioning plate 5 is vertically arranged, and the spraying device and the deburring device are symmetrically arranged at the front side of the positioning plate 5. And the two clamping poles can be vertically and movably arranged through the first servo cylinder 1a, the center of the positioning plate 5 is provided with a notch 5a, all clamping poles 5b are circumf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com