Hull structure based on self-propelled detection robot

A robot and hull technology, applied in the field of hull structure based on self-propelled inspection robots, can solve the problems of poor hull self-stability, deep draft, inability to carry underwater sonar, etc. Guaranteed effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

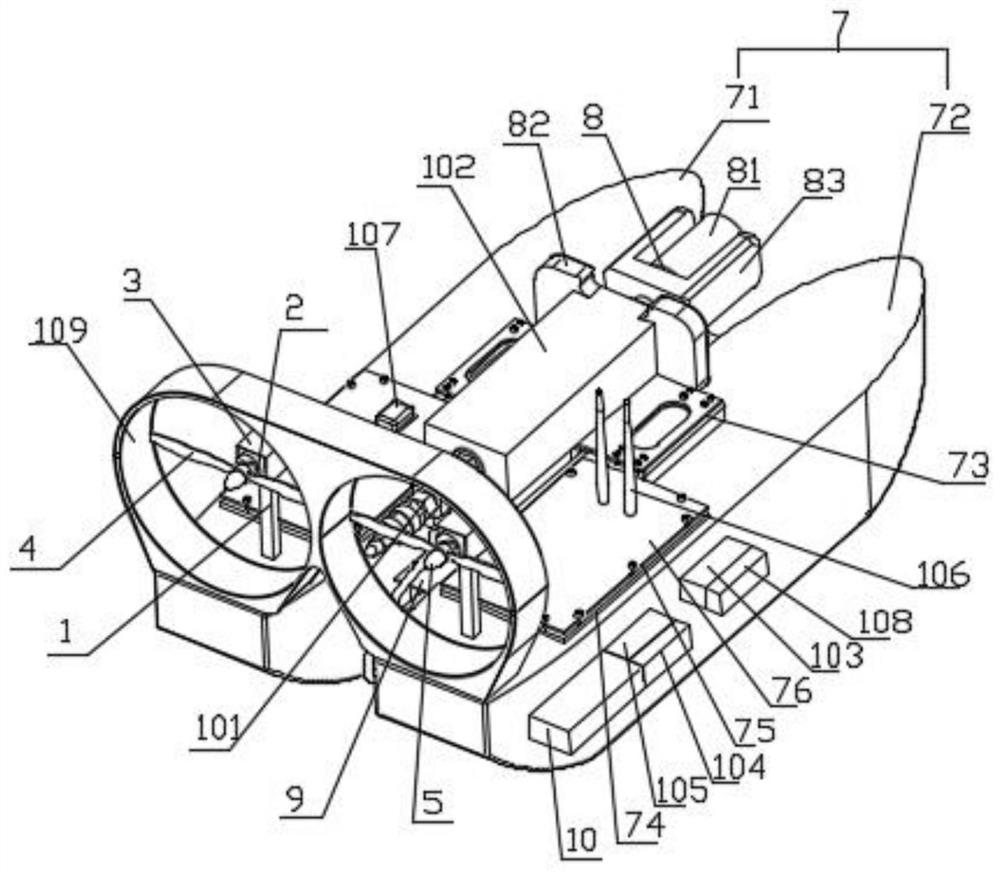

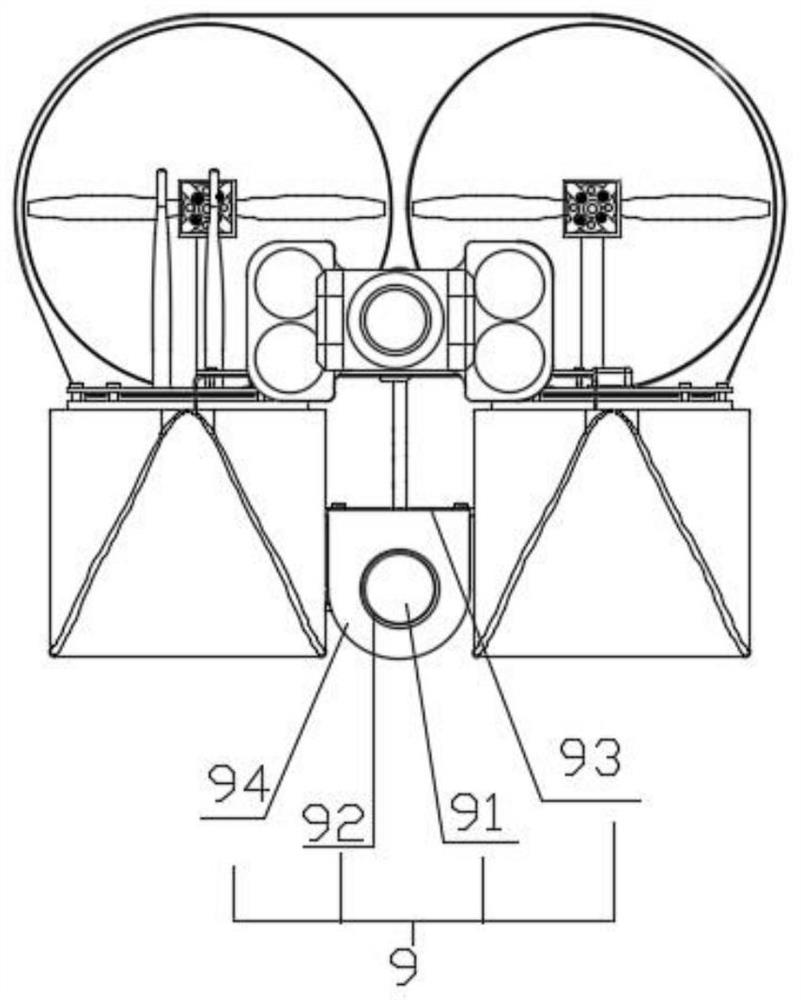

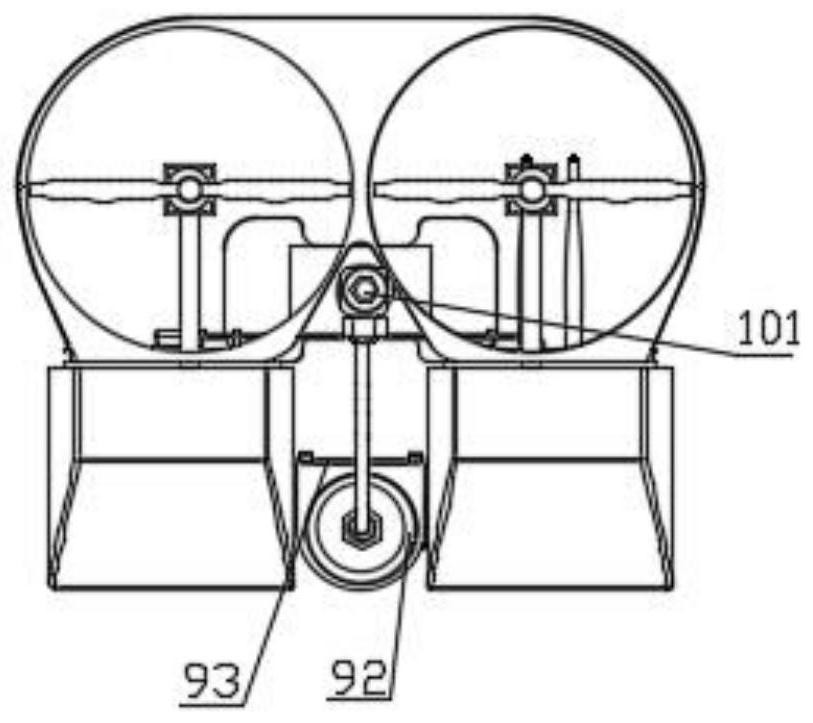

[0028] A hull structure based on a self-propelled detection robot, comprising a hull 7, a fixed bracket 73 and a sonar system 9; respectively fixed in the middle of the left monolithic body 71 and the right monolithic body 72, and the left monolithic body 71 and the right monolithic body 72 are connected together; the sonar system 9 is located at the left monolithic body 71 and the right monolithic body 72, the sonar system 9 is connected and fixed between the left monolithic body 71 and the right monolithic body 72.

[0029] Further, the fore and stern frontal directions of the left monolithic body 71 and the right monolithic body 72 are in the shape of bow and stern warping arcs respectively, and the bow and stern overlooking directions are respectively inwardly curved, while the left monolithic body 71 and the right monolithic body The middle end of the bottom of 72 is straight.

[0030] Further, the top decks of the left monolithic body 71 and the right monolithic body 72...

Embodiment 2

[0041] Such as Figure 1-3 As shown, a box culvert detection robot includes a main robot ship 7, an air negative pressure power system, a CCTV system 8, a sonar system 9, an independent power supply 10, a conversion joint 101, an integrated controller 102, a receiving antenna 103, and a receiving unit 104 and the speed regulation module 105.

[0042] The main robot ship 7 is a catamaran, and the catamaran includes a left monolithic body 71 and a right monolithic body 72 .

[0043] Each monolithic body is formed by aluminum alloy sheet metal processing. The frontal direction of the bow and stern is in the shape of bow warping and stern warping respectively. While reducing the resistance of water flow during navigation.

[0044] Each monolithic body top deck surface is respectively provided with inspection hole and inspection hole seat plate 74, inspection hole seal 75, inspection hole cover plate 76 at the stern portion of the sheet body.

[0045] The inspection hole seat pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com