Online marking machine

A marking machine and manipulator technology, applied in the field of marking machines, can solve problems such as poor applicability, high production cost, and high labor intensity, and achieve the effects of strong applicability, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

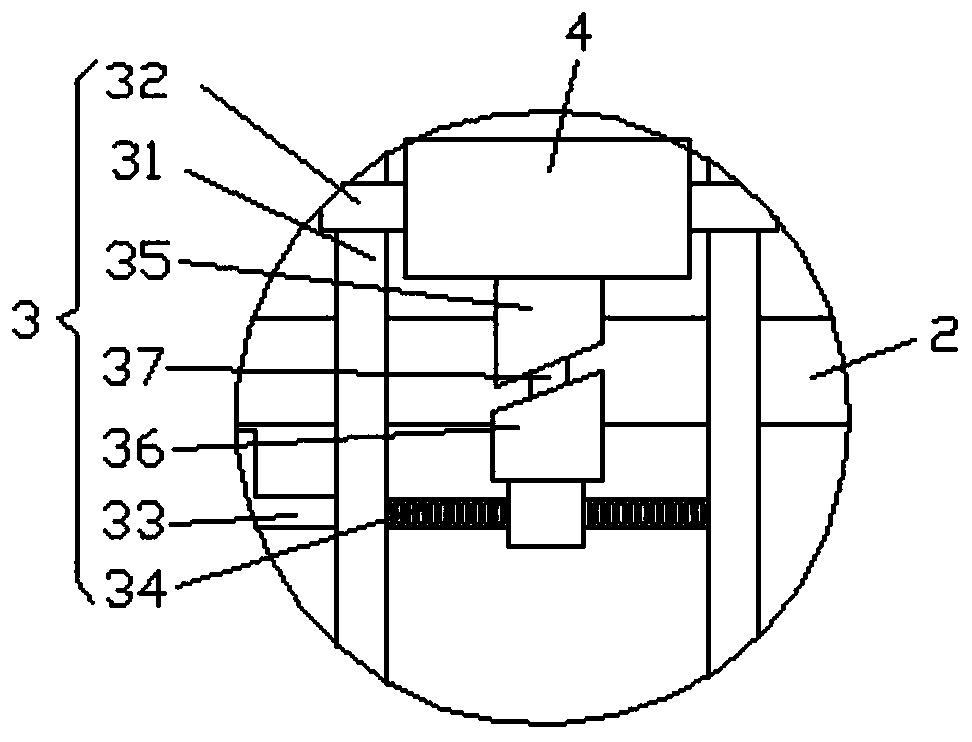

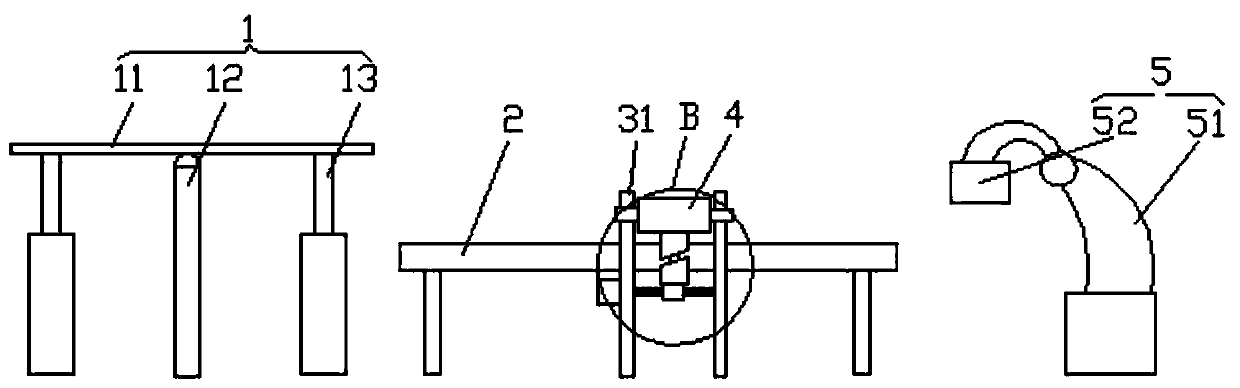

[0042] In this embodiment, the driving mechanism is a crank handle 33, and one end of the crank handle is fixedly connected with one end of the screw rod 34, usually by welding or bolt connection, which is convenient for disassembly and assembly. When the position of the marking mechanism 4 needs to be adjusted, manually shake the handle to drive the screw 34 to rotate, and drive the nut and the lower wedge 36 to reciprocate along the screw 34, thereby adjusting the upper wedge 35 and the marking mechanism 4. location, so as to be applicable to the marking requirements of different specifications of packing boxes or different positions of packing boxes.

Embodiment 2

[0044] In this embodiment, the driving mechanism is a motor 38 . The motor 38 is arranged on one of the guide rods 31 , and its driving end is fixedly connected to one end of the screw rod 34 . When the position of the marking mechanism 4 needs to be adjusted, the motor 38 drives the screw mandrel 34 to rotate, and drives the nut and the lower wedge 36 to move back and forth along the screw mandrel 34, thereby adjusting the positions of the upper wedge 35 and the marking mechanism 4, so that It is suitable for marking requirements of different specifications of packing boxes or different positions of packing boxes.

[0045] In the present invention, the conveying mechanism 2 is a roller conveying line with simple structure and convenient conveying.

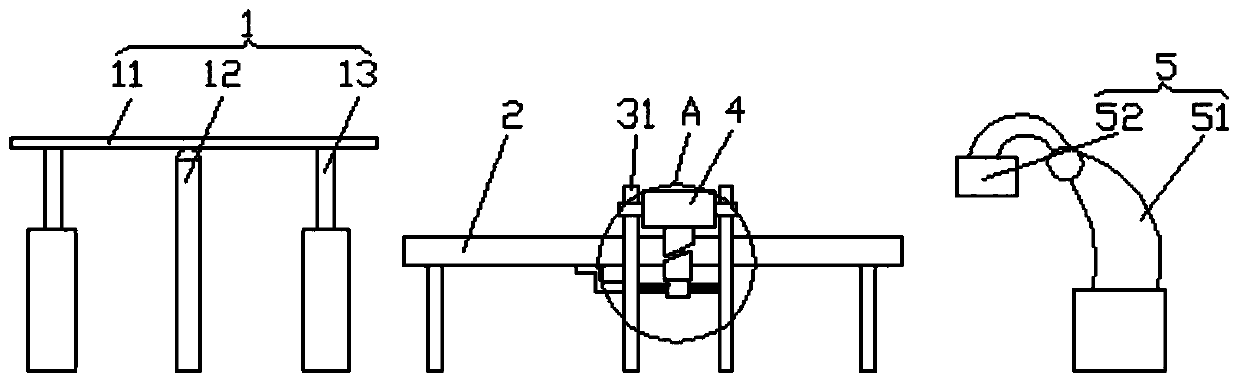

[0046] In the present invention, the feeding mechanism 1 includes a strip slide 11 and two elevating mechanisms 12, both of which are first cylinders, and the two first cylinders are respectively arranged at both ends of the strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com