Heat-resisting and wear-resisting PVC (Polyvinyl Chloride) plastic

A plastic and heat-resistant technology, applied in the field of plastics, can solve the problems of complex process and high cost, and achieve the effects of maintaining heat resistance, improving weather resistance and thermal stability, excellent heat resistance and anti-wear performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

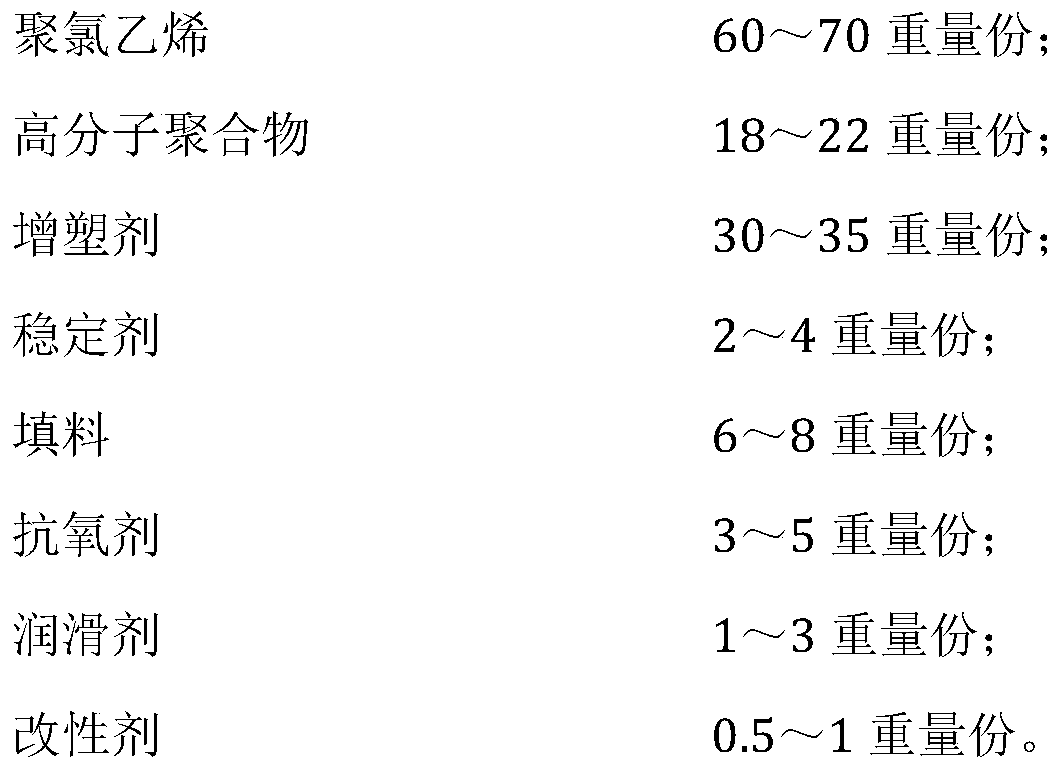

[0037] A heat-resistant and wear-resistant PVC plastic, comprising the following materials by weight:

[0038]

[0039]

[0040] The particle size of barium sulfate and kaolinite is 80nm; the number average molecular weight of polyvinyl chloride is 52000g / mol.

[0041] Preparation method of heat-resistant and wear-resistant PVC plastic:

[0042] 1) Put polyvinyl chloride, magnesium stearate, heptadecafluorodecyltriethoxysilane, oleic acid, rosin, cadmium dialkyldithiocarbamate, and phenyl-α-naphthylamine in a high-speed kneader Medium heating for low-speed mixing, the temperature of the high-speed kneader is controlled at 100-105°C, and at the same time, ethyl heptadecafluoro-n-nonanoate is added to start high-speed mixing;

[0043] 2) When mixing at high speed until the material temperature reaches 90°C, start mixing at low speed again. In the case of mixing at low speed, first add barium sulfate and kaolinite and mix evenly, then add medium density polyethylene, polye...

Embodiment 2

[0046] A heat-resistant and wear-resistant PVC plastic, comprising the following materials by weight:

[0047]

[0048] The particle size of barium sulfate and kaolinite is 90nm; the number average molecular weight of polyvinyl chloride is 53000g / mol.

[0049] Preparation method of heat-resistant and wear-resistant PVC plastic:

[0050] 1) Put polyvinyl chloride, magnesium stearate, heptadecafluorodecyltriethoxysilane, oleic acid, rosin, cadmium dialkyldithiocarbamate, and phenyl-α-naphthylamine in a high-speed kneader Medium heating for low-speed mixing, the temperature of the high-speed kneader is controlled at 100-105°C, and at the same time, ethyl heptadecafluoro-n-nonanoate is added to start high-speed mixing;

[0051] 2) When mixing at high speed until the material temperature reaches 90°C, start mixing at low speed again. In the case of mixing at low speed, first add barium sulfate and kaolinite and mix evenly, then add medium density polyethylene, polyethylene oxide,...

Embodiment 3

[0054] A heat-resistant and wear-resistant PVC plastic, comprising the following materials by weight:

[0055]

[0056] The particle size of barium sulfate and kaolinite is 100nm; the number average molecular weight of polyvinyl chloride is 56000g / mol.

[0057] Preparation method of heat-resistant and wear-resistant PVC plastic:

[0058] 1) Put polyvinyl chloride, magnesium stearate, heptadecafluorodecyltriethoxysilane, oleic acid, rosin, cadmium dialkyldithiocarbamate, and phenyl-α-naphthylamine in a high-speed kneader Medium heating for low-speed mixing, the temperature of the high-speed kneader is controlled at 100-105°C, and at the same time, ethyl heptadecafluoro-n-nonanoate is added to start high-speed mixing;

[0059] 2) When mixing at high speed until the material temperature reaches 90°C, start mixing at low speed again. In the case of mixing at low speed, first add barium sulfate and kaolinite and mix evenly, then add medium density polyethylene, polyethylene oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com