Flame-retardant and weather-resistant PVC cable material

A cable material and weather-resistant technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems affecting the physical and mechanical properties and processing of cable materials, achieve good compatibility, improve anti-aging performance, improve weather resistance and The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

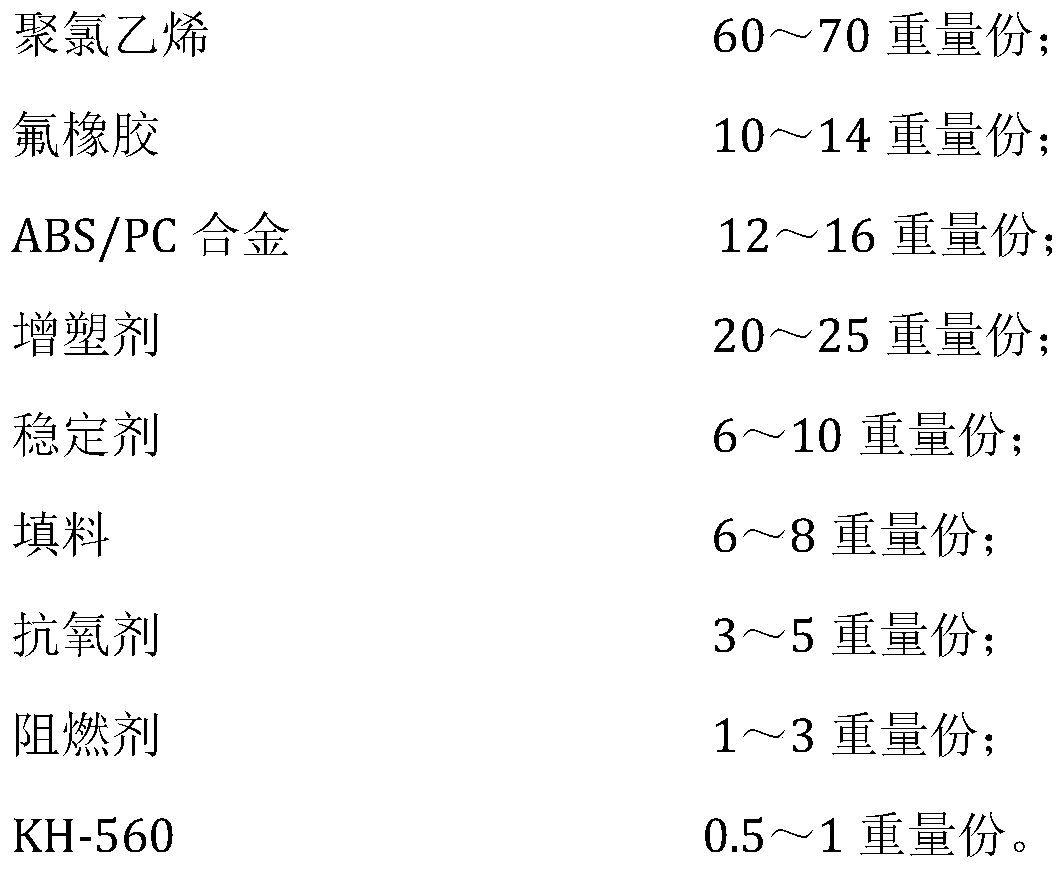

[0034] A flame-retardant and weather-resistant PVC cable material, comprising the following materials by weight:

[0035]

[0036]

[0037] The particle size of titanium carbide and lithium fluoride is 70nm; the number average molecular weight of ABS / PC alloy is 6000g / mol.

[0038] Preparation method of flame-retardant and weather-resistant PVC cable material:

[0039] 1) Put polyvinyl chloride, triphenyl tin acetate, triethyl antimony, zinc butyldithiocarbamate, zinc 2-mercaptobenzothiazole, melamine cyanurate, and decabromodiphenyl ether in high-speed kneading Heat in the machine for low-speed mixing, control the temperature of the high-speed kneader at 105-110°C, add isobutyl p-hydroxybenzoate and ethylene dichloride at the same time, start high-speed mixing;

[0040] 2) When mixing at high speed until the material temperature reaches 90°C, start mixing at low speed again. In the case of mixing at low speed, first add titanium nitride, lithium fluoride, KH-560 and mi...

Embodiment 2

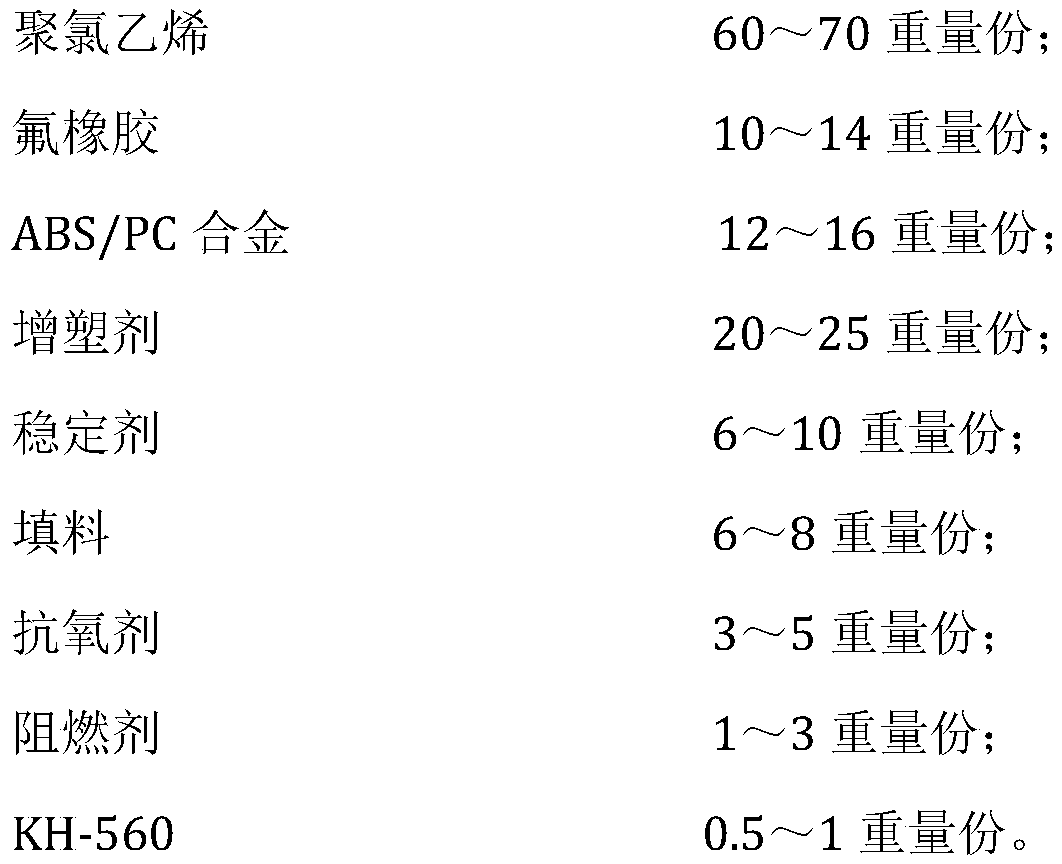

[0043] A flame-retardant and weather-resistant PVC cable material, comprising the following materials by weight:

[0044]

[0045]

[0046] The particle size of titanium carbide and lithium fluoride is 80nm; the number average molecular weight of ABS / PC alloy is 6200g / mol.

[0047] Preparation method of flame-retardant and weather-resistant PVC cable material:

[0048] 1) Put polyvinyl chloride, triphenyl tin acetate, triethyl antimony, zinc butyldithiocarbamate, zinc 2-mercaptobenzothiazole, melamine cyanurate, and decabromodiphenyl ether in high-speed kneading Heat in the machine for low-speed mixing, control the temperature of the high-speed kneader at 105-110°C, add isobutyl p-hydroxybenzoate and ethylene dichloride at the same time, start high-speed mixing;

[0049] 2) When mixing at high speed until the material temperature reaches 90°C, start mixing at low speed again. In the case of mixing at low speed, first add titanium nitride, lithium fluoride, KH-560 and mix ...

Embodiment 3

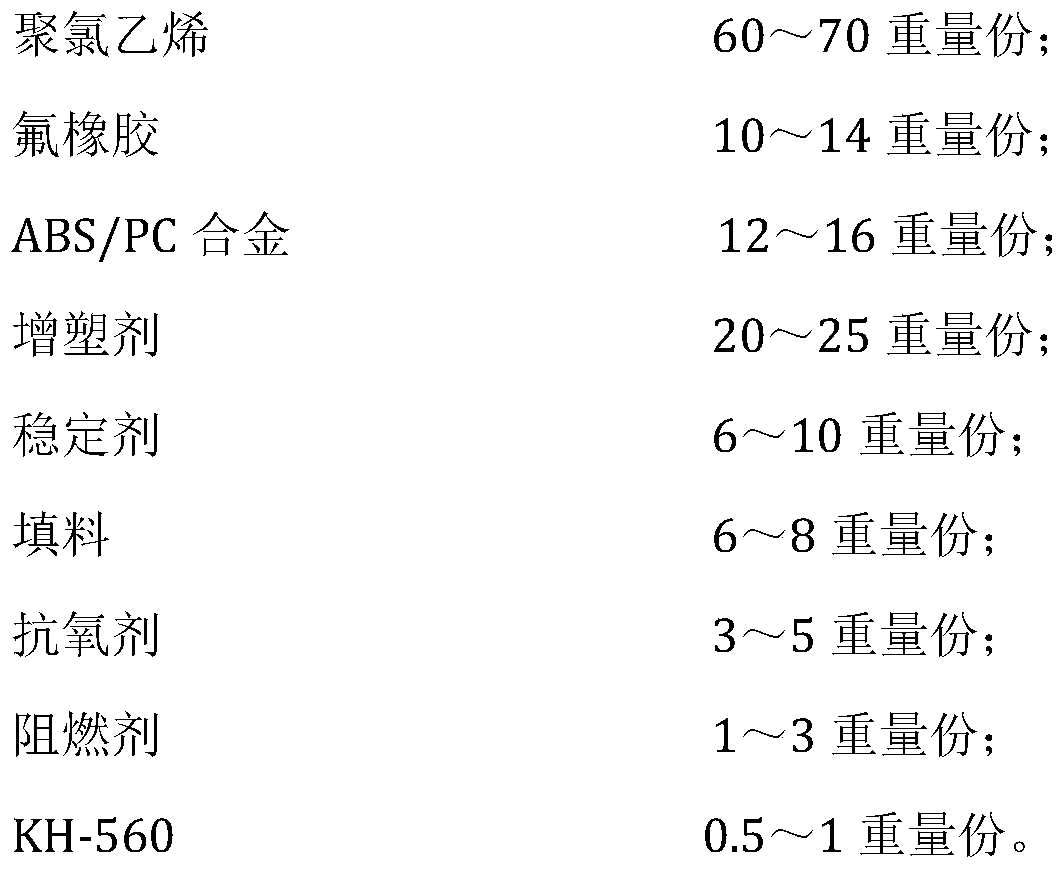

[0052] A flame-retardant and weather-resistant PVC cable material, comprising the following materials by weight:

[0053]

[0054]

[0055] The particle size of titanium carbide and lithium fluoride is 90nm; the number average molecular weight of ABS / PC alloy is 6500g / mol.

[0056] Preparation method of flame-retardant and weather-resistant PVC cable material:

[0057] 1) Put polyvinyl chloride, triphenyl tin acetate, triethyl antimony, zinc butyldithiocarbamate, zinc 2-mercaptobenzothiazole, melamine cyanurate, and decabromodiphenyl ether in high-speed kneading Heat in the machine for low-speed mixing, control the temperature of the high-speed kneader at 105-110°C, add isobutyl p-hydroxybenzoate and ethylene dichloride at the same time, start high-speed mixing;

[0058] 2) When mixing at high speed until the material temperature reaches 90°C, start mixing at low speed again. In the case of mixing at low speed, first add titanium nitride, lithium fluoride, KH-560 and mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com