A kind of method and application of fireworks absolute oil prepared by floating oil method

A technology of fireworks and floating oil, which is applied in the field of flavors and fragrances for tobacco, which can solve the problems that the power of the flash extractor should not be too large, and achieve the effects of rich variety, guaranteed stability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

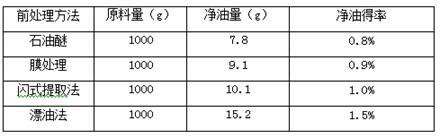

Problems solved by technology

Method used

Image

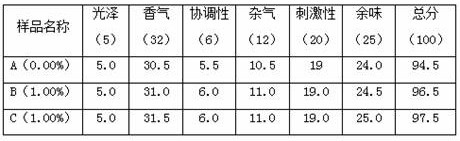

Examples

Embodiment 1

[0047] A kind of method for preparing fireworks absolute by floating oil method, comprises the steps:

[0048] Step (1), extraction: perform reflux extraction on the fireworks, filter and take the filtrate to obtain the extract;

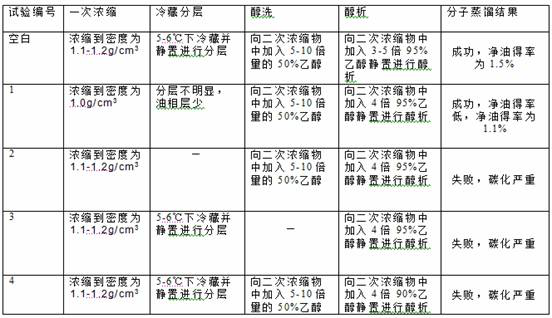

[0049] Step (2), concentration: Concentrate the extract obtained in step (1) at a temperature of 65°C to a density of 1.15g / cm 3 , to obtain a concentrated solution;

[0050] Step (3), refrigerated stratification: put the concentrated solution obtained in step (2) under refrigeration at 6°C for stratification to obtain the upper layer of oily substance and the lower layer of water-soluble substance;

[0051] Step (4), secondary concentration and alcohol washing: at a temperature of 65°C, the upper oily substance obtained in step (3) is subjected to secondary vacuum concentration to obtain a secondary concentrate; Wash with 40% ethanol, pour out the supernatant, and keep the lower layer of oily paste;

[0052] Step (5), three times of concentration...

Embodiment 2

[0059] A kind of method for preparing fireworks absolute by floating oil method, comprises the steps:

[0060] Step (1), extraction: perform reflux extraction on the fireworks, filter and take the filtrate to obtain the extract;

[0061] Step (2), concentration: Concentrate the extract obtained in step (1) at a temperature of 60°C to a density of 1.1g / cm 3 , to obtain a concentrated solution;

[0062] Step (3), refrigerated stratification: put the concentrated solution obtained in step (2) under refrigeration at 5°C for stratification to obtain the oily substance in the upper layer and the water-soluble substance in the lower layer;

[0063] Step (4), secondary concentration and alcohol washing: at a temperature of 60°C, perform secondary vacuum concentration on the oily substance in the upper layer obtained in step (3) to obtain a secondary concentrate; add a mass concentration of Carry out alcohol washing with 60% ethanol, pour out the supernatant, and keep the lower oily ...

Embodiment 3

[0079] A kind of method for preparing fireworks absolute by floating oil method, comprises the steps:

[0080] Step (1), extraction: perform reflux extraction on the fireworks, filter and take the filtrate to obtain the extract;

[0081] Step (2), concentration: Concentrate the extract obtained in step (1) at a temperature of 70°C to a density of 1.2g / cm 3 , to obtain a concentrated solution;

[0082] Step (3), refrigerated stratification: put the concentrated solution obtained in step (2) under refrigeration at 8°C for stratification to obtain the upper oily substance and the lower water-soluble substance;

[0083] Step (4), secondary concentration and alcohol washing: at a temperature of 70°C, the upper oily substance obtained in step (3) is subjected to secondary vacuum concentration to obtain a secondary concentrate; Wash with 50% ethanol, pour out the supernatant, and keep the lower layer of oily paste;

[0084] Step (5), three times of concentration, alcohol analysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com