A joint structure and construction method of section steel wrapped concrete columns and steel beams

A technology of concrete column and node structure, applied in building construction, construction and other directions, can solve the problems of low assembly process efficiency, inconvenient welding assembly, unfavorable construction speed and quality, etc. The effect of construction speed and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

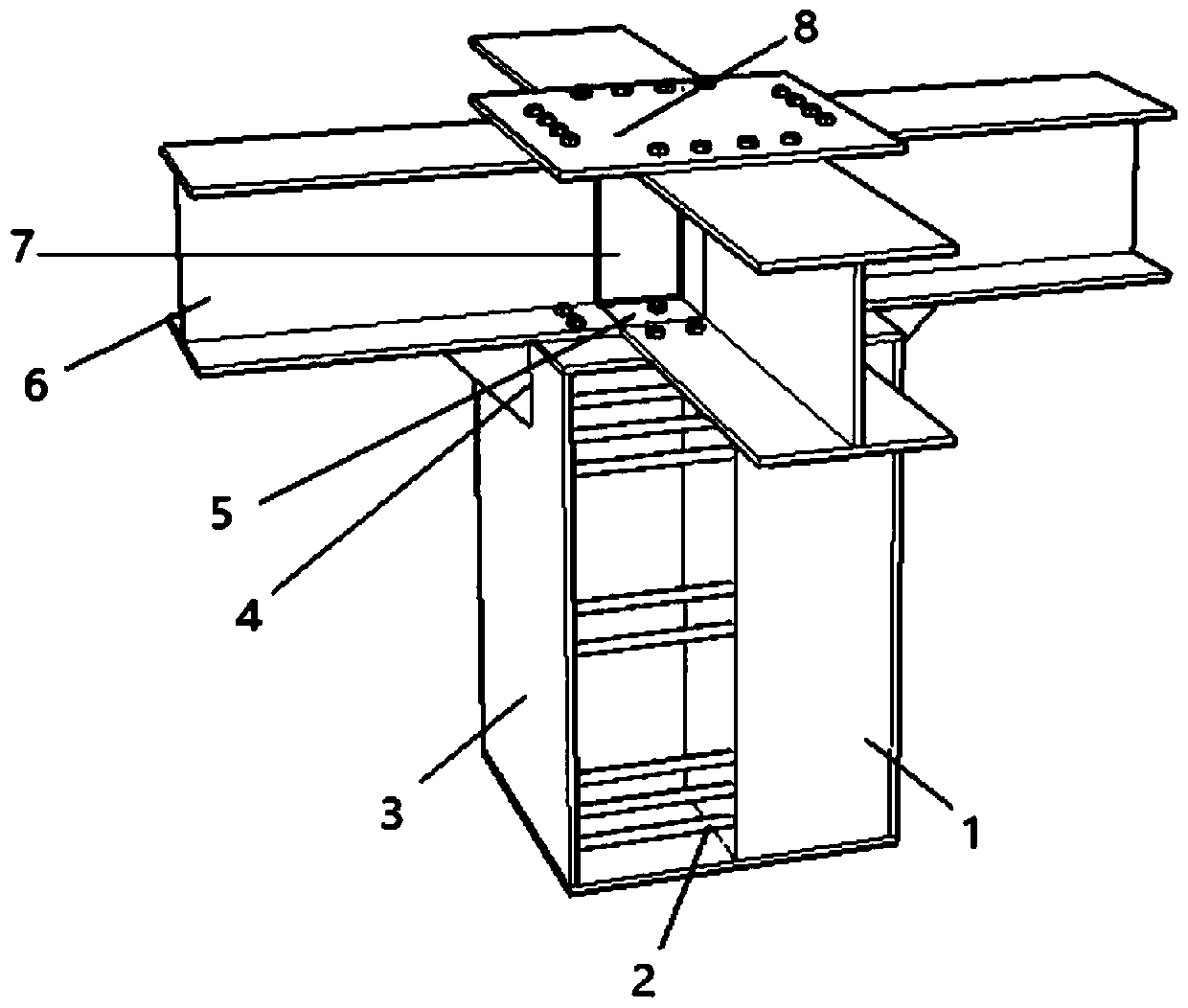

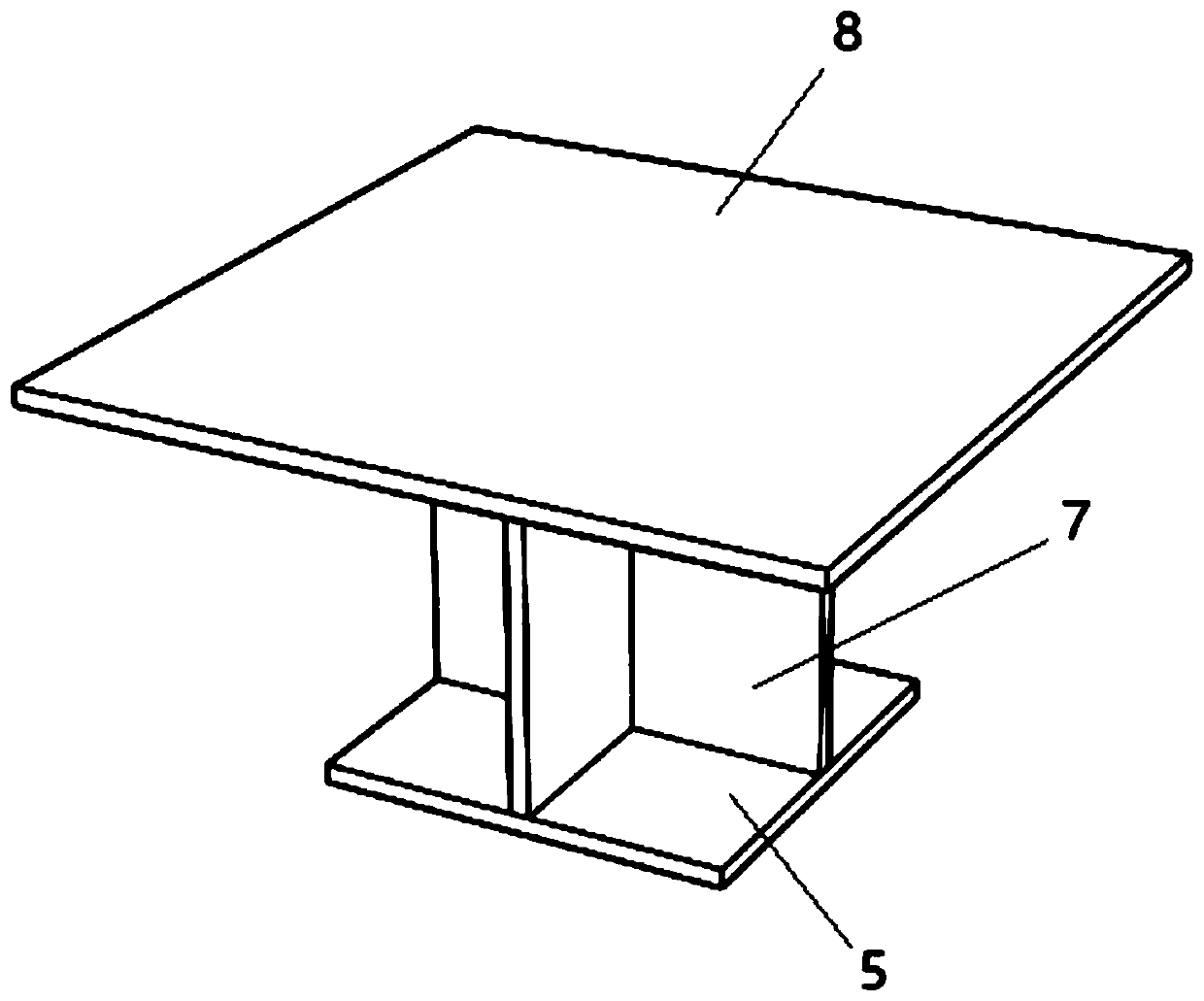

[0027] see Figure 1-2 , a joint structure of concrete columns and steel beams partially wrapped by section steel, including closed H-shaped steel 3, recycled concrete 1 is poured inside the closed H-shaped steel 3, a cross-shaped steel frame 7 is arranged on the closed H-shaped steel 3, and the cross-shaped steel An upper steel plate 8 and a lower steel plate 5 are respectively horizontally fixed on the upper and lower bottom of the frame 7, the lower steel plate 5 is fixed on the closed H-shaped steel 3, and the cross-shaped steel frame 7 is evenly provided with four steel plates fixedly connected with the lower steel plate 5 and the upper steel plate 8. I-beam 6.

[0028] In order to improve the structural strength of the connection between the I-beam 6 and the closed H-shaped steel 3 , a corbel 4 is welded and fixed between the I-beam 6 and the closed H-shaped steel 3 .

[0029] In order to ensure the supporting strength of the closed H-shaped steel 3, the upper and lower...

Embodiment 2

[0031] A construction method for a joint structure of concrete columns and steel beams partially wrapped by section steel, specifically comprising the following steps:

[0032] Step 1, welding and fixing the circular cross-section transverse steel rod 2 in the closed H-shaped steel 3;

[0033] Step 2: Center and level the four I-beams 6 on the upper end of the closed H-shaped steel 3. The extension direction of the four I-beams 6 corresponds to the direction of the four side walls of the closed H-shaped steel 3. The I-beams 6 pass through the bolts. Locked and connected to the upper steel plate of the closed H-beam 3;

[0034] Step 3, placing the cross-shaped steel frame 7 on the closed H-shaped steel 3, and fixing the cross-shaped steel frame 7 and the top of the closed H-shaped steel 3 through bolts;

[0035] Step 4. Weld and fix the upper steel plate 8 and the lower steel plate 5 to the top and bottom of the cross-shaped steel frame 7 respectively. The area of the lower ...

Embodiment 3

[0040] A construction method for a joint structure of concrete columns and steel beams partially wrapped by section steel, specifically comprising the following steps:

[0041] Step 1, welding and fixing the circular cross-section transverse steel rod 2 in the closed H-shaped steel 3;

[0042] Step 2: Center and level the four I-beams 6 on the upper end of the closed H-shaped steel 3. The extension direction of the four I-beams 6 corresponds to the direction of the four side walls of the closed H-shaped steel 3. The I-beams 6 pass through the bolts. Locked and connected to the upper steel plate of the closed H-beam 3;

[0043] Step 3, placing the cross-shaped steel frame 7 on the closed H-shaped steel 3, and fixing the cross-shaped steel frame 7 and the top of the closed H-shaped steel 3 through bolts;

[0044] Step 4. Weld and fix the upper steel plate 8 and the lower steel plate 5 to the top and bottom of the cross-shaped steel frame 7 respectively. The area of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com