Pre-burying arrangement mode and method of downpipes simultaneously used as demolishing blast holes in building peripheral columns

An arrangement method and downspout technology, applied in the direction of roof drainage, etc., can solve the problems of easy weathering and corrosion of fixed blocks, short service life, easy freezing, etc., achieve significant economic and social benefits, improve the overall aesthetic effect, and avoid noise and dust pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

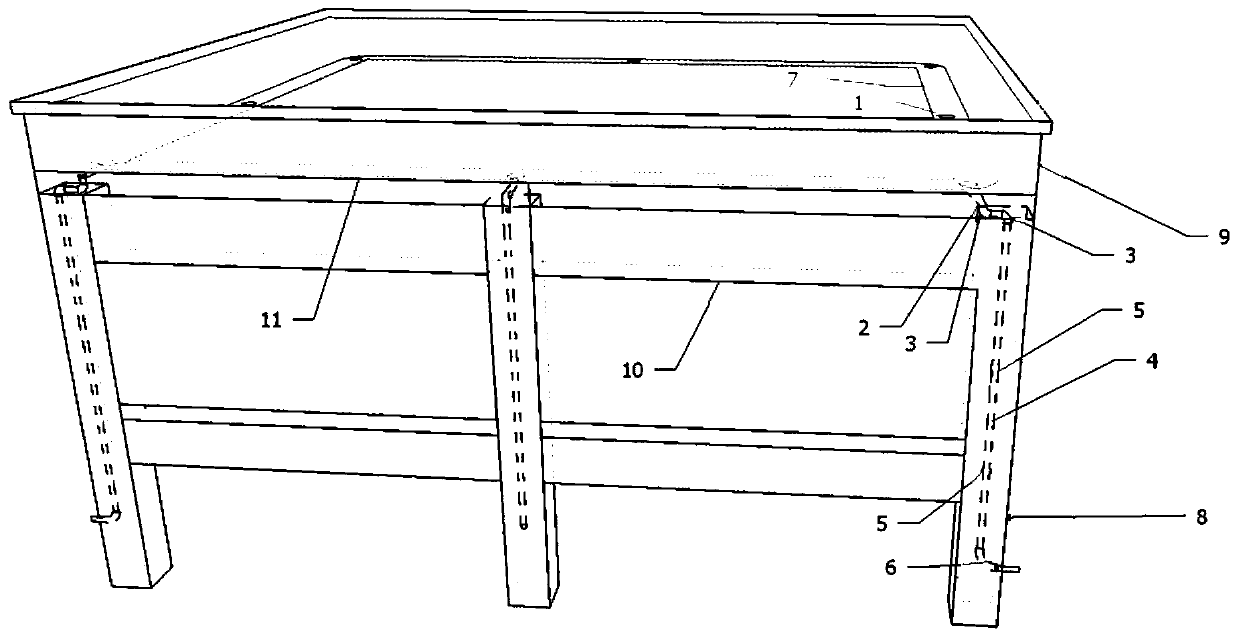

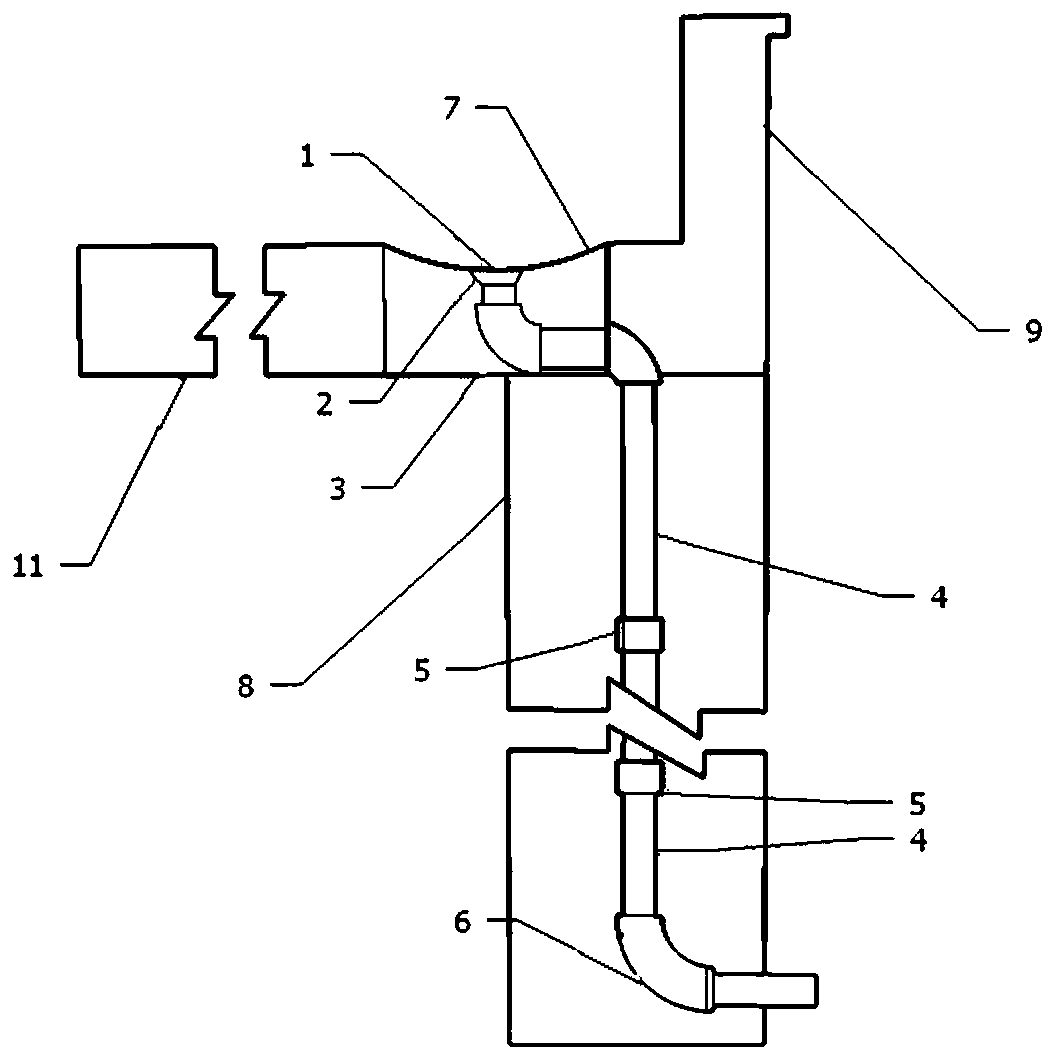

[0045] A three-story building with a height of 9.8m and a floor height of 3m has a flat roof 17, a parapet 9 on the roof, and a gutter 7 on the roof. The size of the reinforced concrete columns around the building is 0.4m×0.4m×9m. The specific steps for the pre-embedded layout of the downspout that doubles as the demolition of the blast hole in the surrounding columns of the building are as follows:

[0046]1) Erection of steel cages for the surrounding columns of the first floor of the building, and erect the first section of downspout pipe 4 with a diameter of 40 mm in the steel cage frame, the lower end of the downpipe is connected to a 135° elbow 6, and the height of the downpipe body is tied with thin iron wires 15 at intervals of 1 m (See Figure 8 ), and be fixed on four column longitudinal bars 14 or column stirrups 13 after tightening to form a cross. Then support the formwork so that the lower end of the 135° elbow protrudes out of the formwork; the upper end of the...

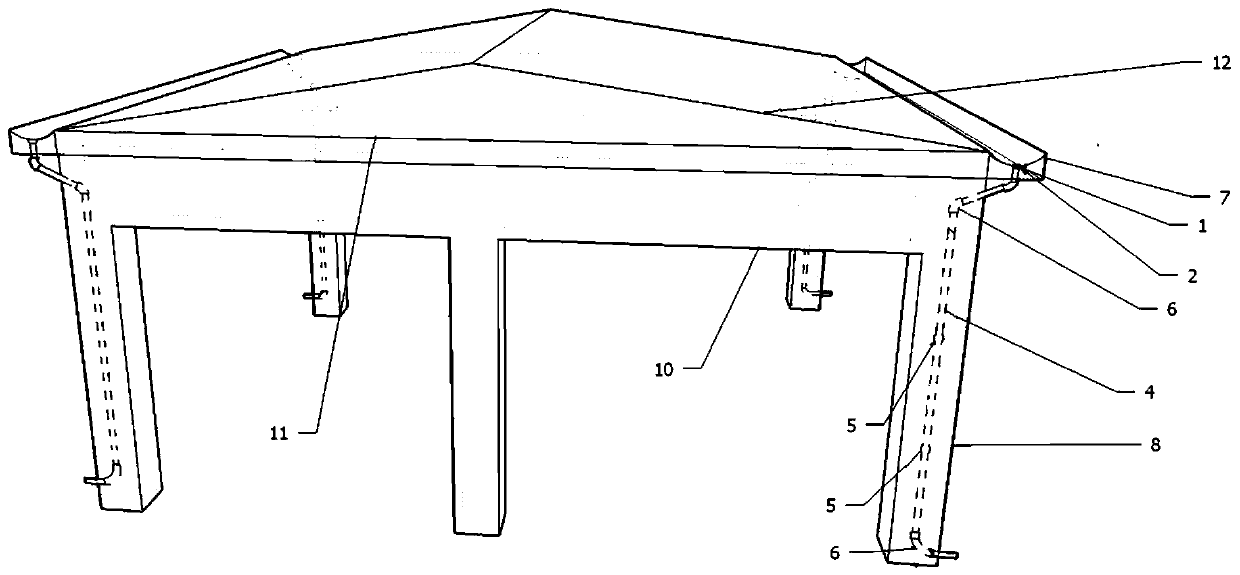

Embodiment 2

[0051] Embodiment 2, certain three storey height 9.8m, the building of storey height 3m, slope roof 12, be provided with gutter 16 outside the eaves, the size of reinforced concrete column around the building is 0.4m * 0.4m * 9m.

[0052] 1) Erect a steel cage for the surrounding columns of the building on the first floor, and erect the first section of downpipe 4 with a diameter of 40 mm in the steel cage frame. The lower end of the downpipe is connected to a 135° elbow 6. Bind iron wires and fix them on the four longitudinal columns 14 or column stirrups 13 after tightening to form a cross; then support the formwork so that the lower end of the 135° elbow protrudes out of the formwork; the upper end of the downpipe is higher than the surrounding column formwork of the building The top is 20-30cm, and the upper opening is sealed with a plastic bag;

[0053] 2) Pouring concrete to the top of the peripheral column formwork of the first-floor building;

[0054] 3) Erect the rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com