Rotary type air centrifugal force generating device for centrifugal fan

A generation device and a centrifugal fan technology, which are applied to components of pumping devices for elastic fluids, pump devices, machines/engines, etc., can solve problems that affect the service life of motors and fans, low efficiency, energy waste, etc., and achieve Enhance air centrifugal effect, reduce noise and improve mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

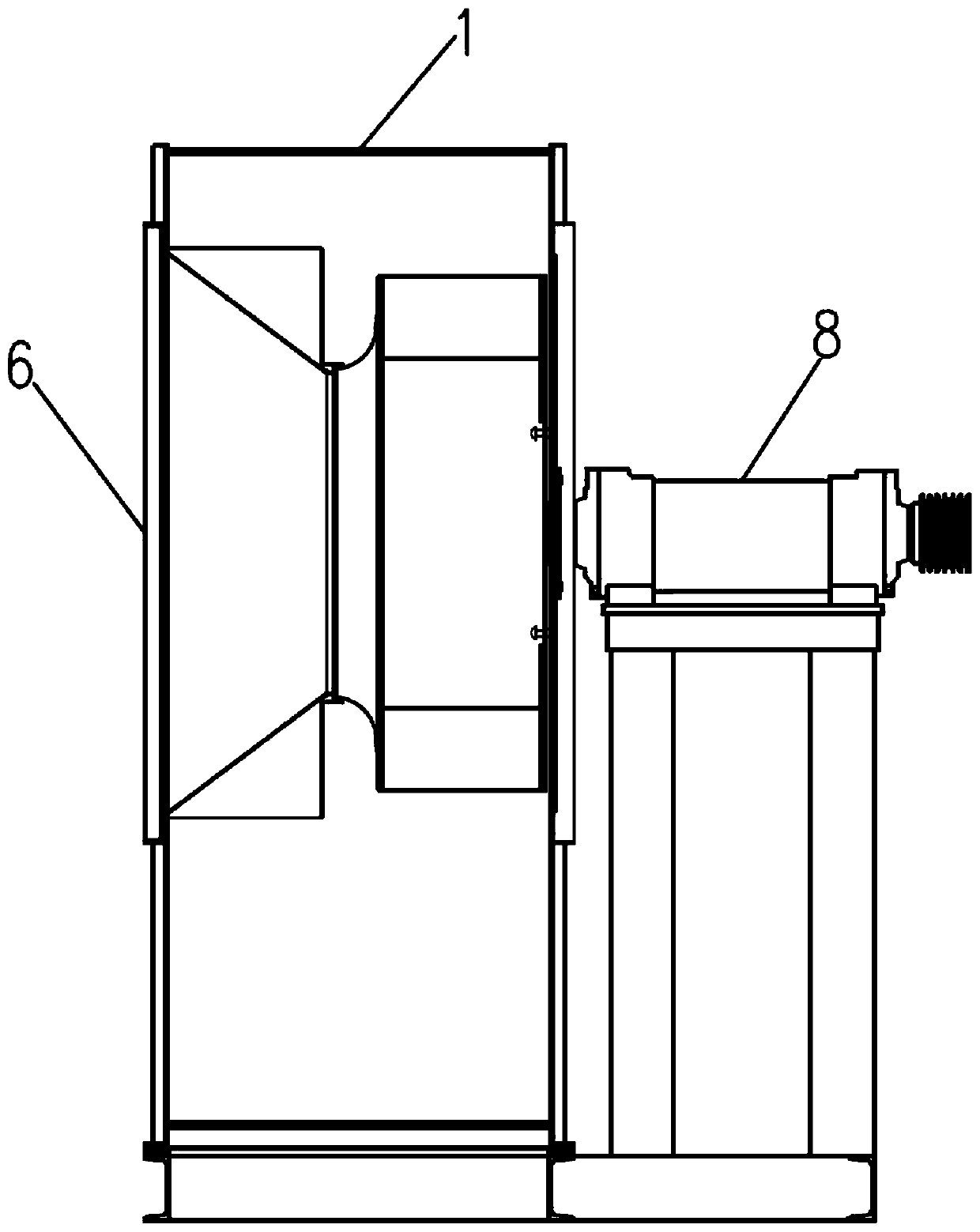

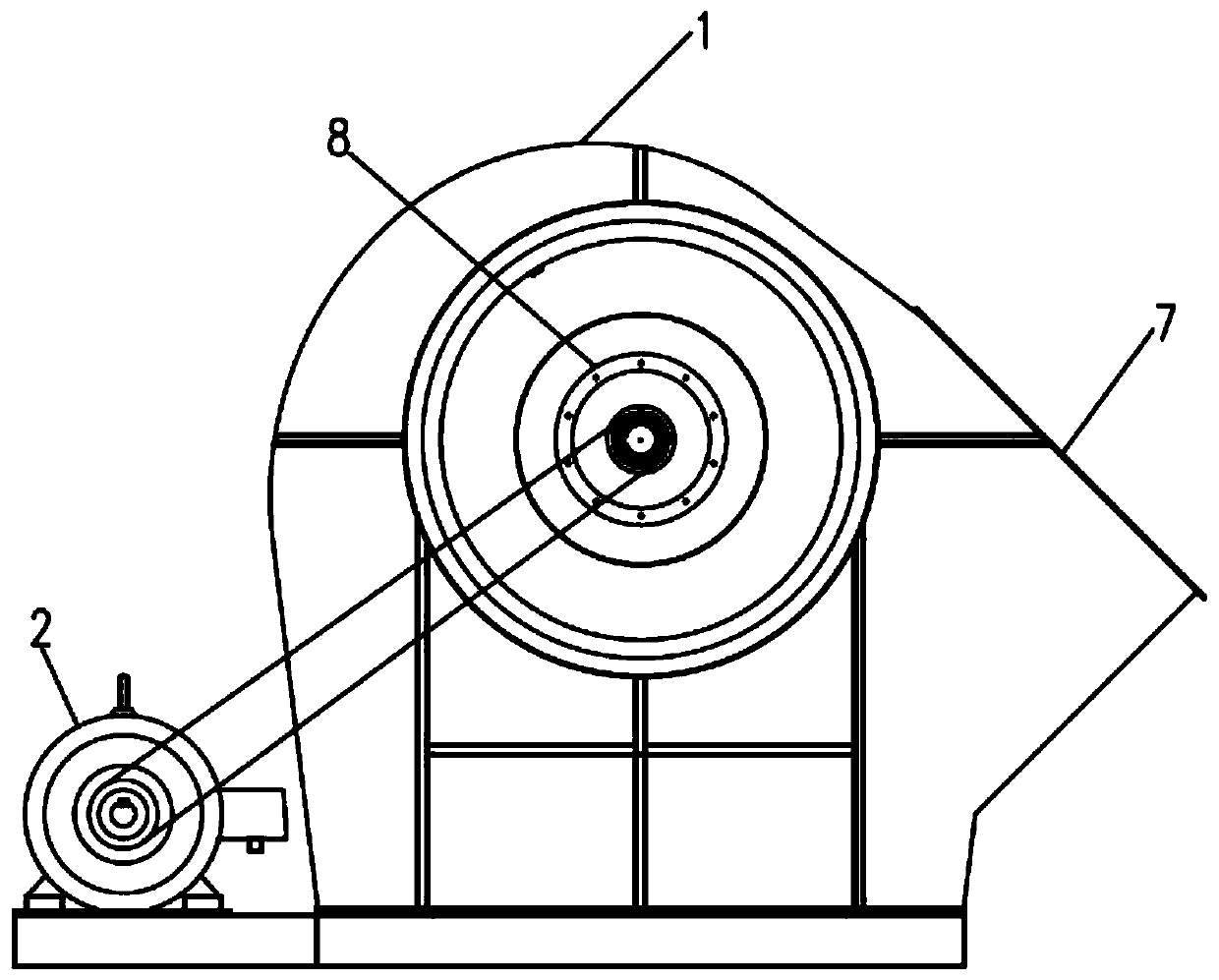

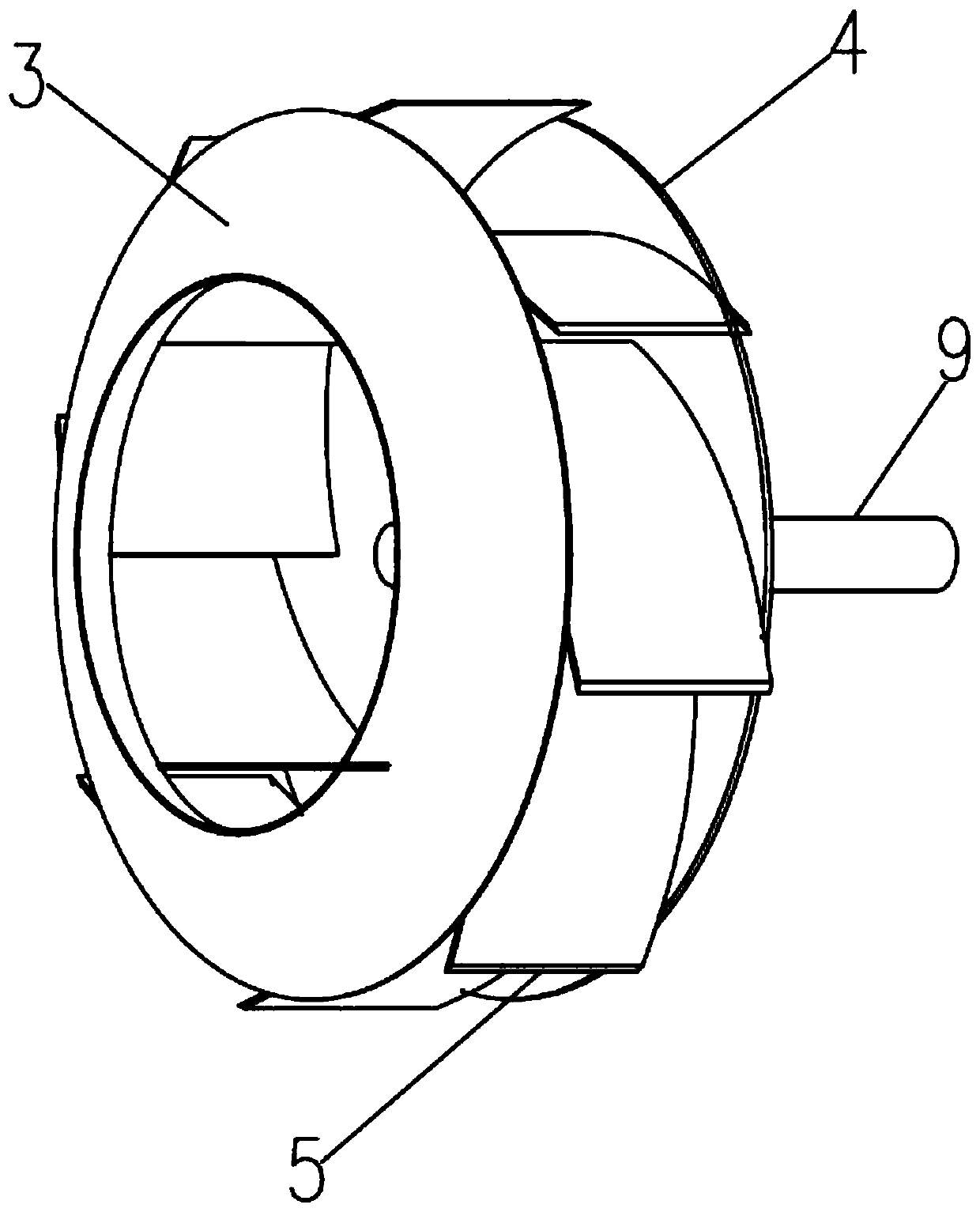

[0024] see figure 1 , figure 2 with image 3 As shown, the device is installed in the volute 1 of the centrifugal fan to form a centrifugal fan: including the drive motor 2, the volute 1 and the air inlet 6 arranged on the left side of the volute 1 and along the tangential direction of the circular shell of the volute 1 The air outlet passage 7 provided is provided with a rotary air centrifugal force generator in the volute 1, and the drive motor 2 drives the rotary air centrifugal force generator to rotate, so that the air in the volute 1 generates centrifugal force, and the air on the side of the air inlet 6 Inhale the air outlet channel 7, the rotary air centrifugal force generating device includes the left side wall plate 3 of the spiral channel, the right side wall plate 4 of the spiral channel and a group of spiral channel partition plates 5, the left side wall plate 3 of the spiral channel is an annular plate, and the annular plate The inner circular hole of the spir...

Embodiment 2

[0027] see figure 1 , figure 2 with Figure 4 As shown, the device is installed in the volute 1 of the centrifugal fan to form a centrifugal fan: including the drive motor 2, the volute 1 and the air inlet 6 arranged on the left side of the volute 1 and along the tangential direction of the circular shell of the volute 1 The air outlet passage 7 provided is provided with a rotary air centrifugal force generator in the volute 1, and the drive motor 2 drives the rotary air centrifugal force generator to rotate, so that the air in the volute 1 generates centrifugal force, and the air on the side of the air inlet 6 Inhalation air outlet channel 7 is characterized in that: the rotary air centrifugal force generating device includes the left side wall plate 3 of the spiral channel and a group of spiral channel partition plates 5, the left side wall plate 3 of the spiral channel is an annular plate, and the inner circular hole of the annular plate Corresponding to the air inlet 6 ...

Embodiment 3

[0031] see figure 1 , figure 2 with Figure 5 As shown, the device is installed in the volute 1 of the centrifugal fan to form a centrifugal fan: including the drive motor 2, the volute 1 and the air inlet 6 arranged on the left side of the volute 1 and along the tangential direction of the circular shell of the volute 1 The air outlet passage 7 provided is provided with a rotary air centrifugal force generator in the volute 1, and the drive motor 2 drives the rotary air centrifugal force generator to rotate, so that the air in the volute 1 generates centrifugal force, and the air on the side of the air inlet 6 Inhale the air outlet channel 7, the rotary air centrifugal force generating device includes the right side wall plate 4 of the spiral channel and a group of spiral channel partition plates 5, the right side wall plate 4 of the spiral channel is a circular plate, and a group of spiral channel partition plates 5 are The arc-shaped plate, the spiral channel partition p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com