Hydraulically powered mine axial flow ventilation fan

An axial flow fan and mine technology, applied in liquid fuel engines, mine/tunnel ventilation, axial flow pumps, etc., can solve the problems of poor bearing force, inconvenient maintenance and poor motor working environment, etc. The effect of stepless speed regulation is easy to achieve, the stress condition is improved, and the maintenance workload is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

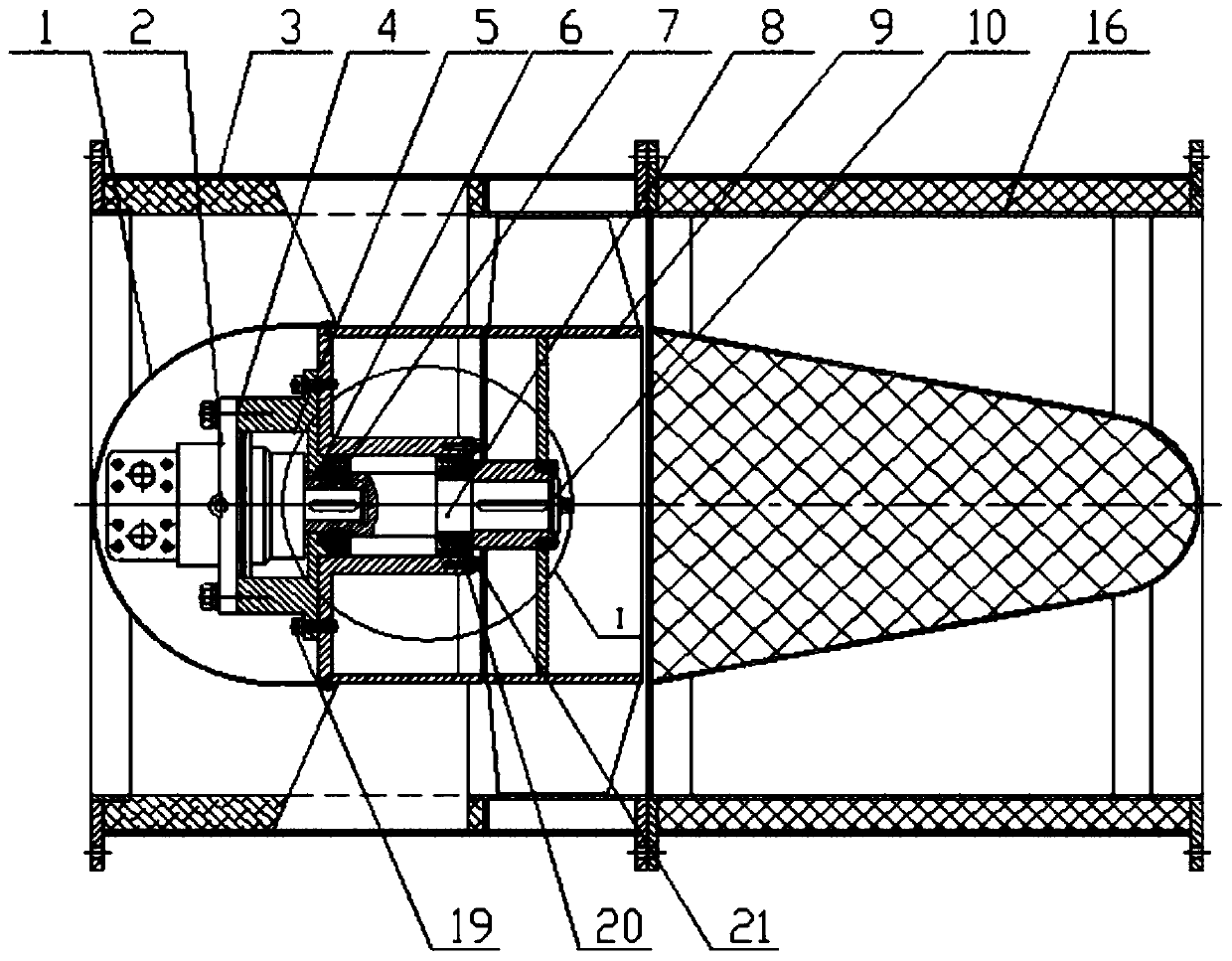

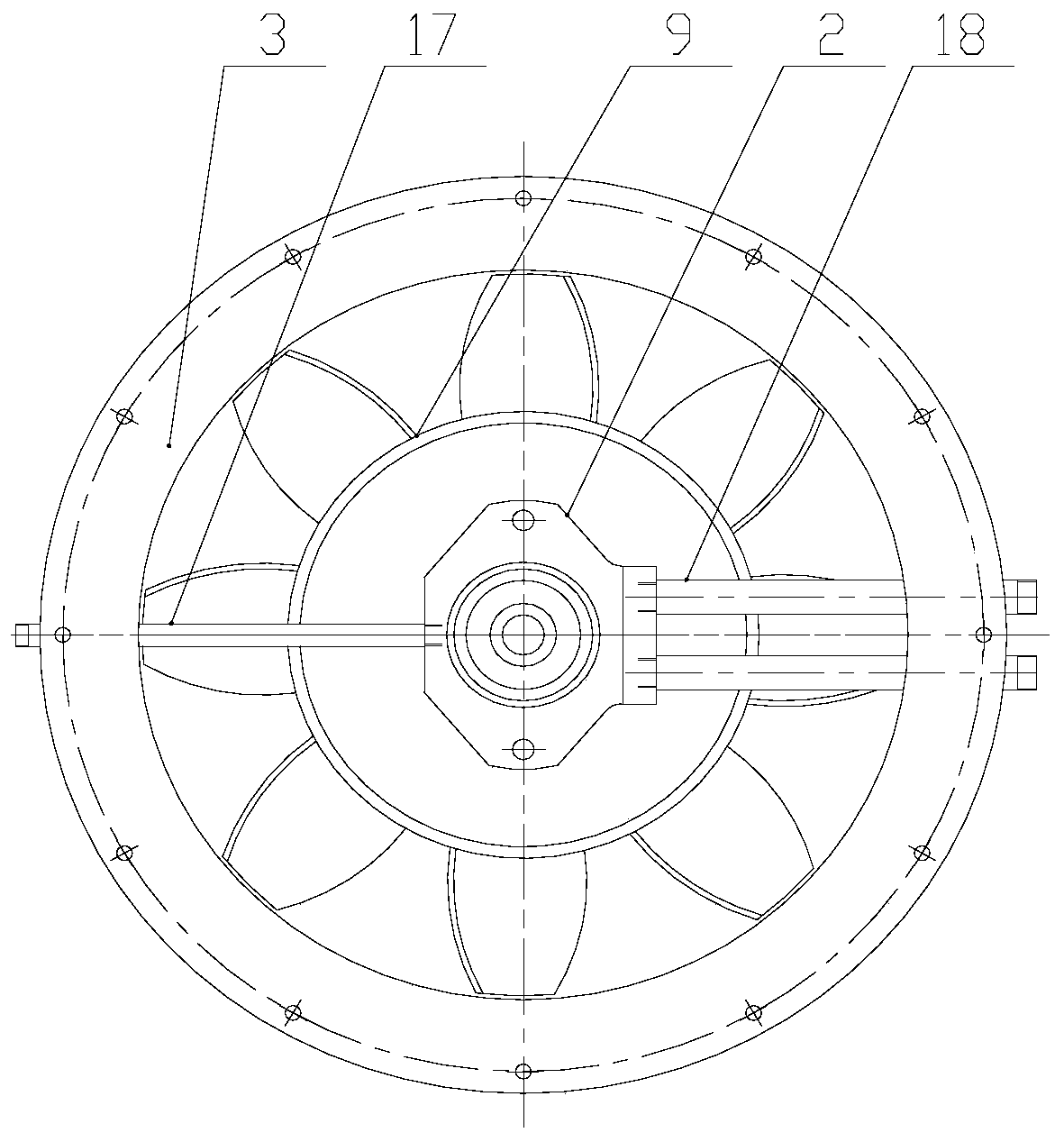

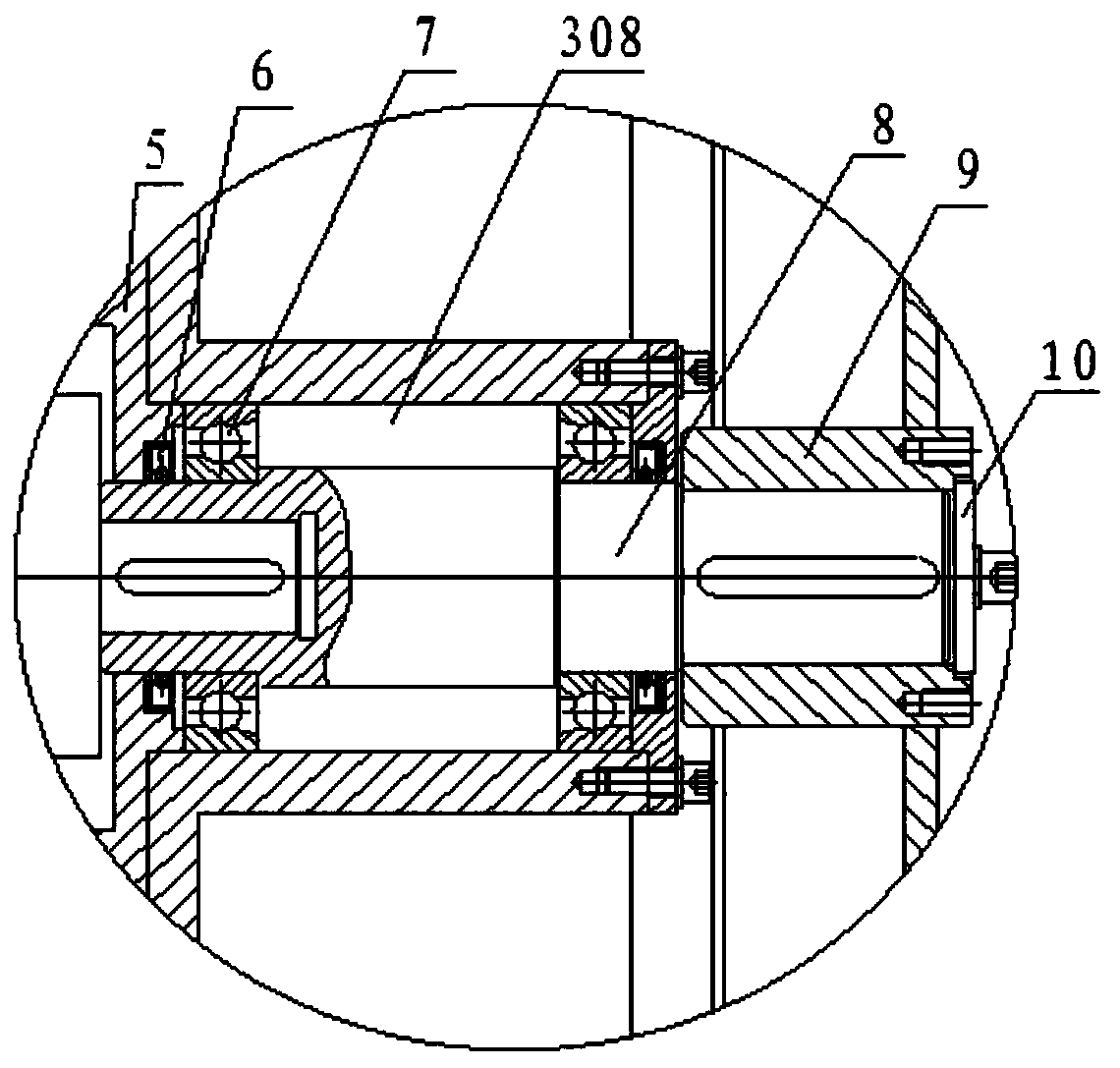

[0036] see Figure 1 to Figure 7 , the hydraulically driven mine axial flow fan of the present embodiment includes an outer shell 3 and a first-stage impeller 9, and the air intake end of the fan is provided with a shroud 1; it also includes an inner cylinder 305, a hydraulic motor 2, and a motor support Seat 5, adapter shaft 8. from figure 1 It can be seen that the shroud 1 is arranged outside the hydraulic motor 2, and the shroud is either a thin-walled hemispherical shape or a semi-closed cone shape. The shroud 1 of this embodiment is a thin-walled hemispherical shape, and the shroud 1 The open end of the inner cylinder body 305 is fixed on the left end face; the air outlet end of the fan in this embodiment is also provided with a shroud, which is a thin-walled semi-closed cone. The inner cylinder 305 is fixedly connected to the inside of the outer shell 3 through the web ribs 306, the right end of the motor support base 5 is fixed to the air inlet end of the left end of ...

Embodiment 2

[0043] see Figure 8 , this embodiment is composed of two such as embodiment 1 figure 1 The vertical sectional view of the hydraulically driven mine axial flow fan composed of the combined fan with counter-rotating structure is shown. Two or more mine hydraulically driven axial flow fans of the present invention with the same specifications are combined into a combined fan with a counter-rotating structure and a multi-stage structure. like Figure 8 As shown, when two axial flow fans form a combined fan with counter-rotating structure, the impellers of the two fans are installed adjacent to each other, and the impellers of the two fans have different numbers of blades, different blade angles, and the impellers rotate in opposite directions. Figure 8 Among them, 9 represents the primary impeller, 11 represents the secondary impeller, 12 represents the first flat key, 14 represents the second flat key, and 15 represents the air outlet diffuser. Figure 8 In all the other lab...

Embodiment 3

[0045] see Figure 9 , this embodiment is a structural schematic diagram of a large axial flow fan driven by hydraulic pressure of the present invention. In this embodiment, the axial flow fan is a counter-rotating mine main fan, and the lower end of the shell has a foot structure, and other support structures can also be used; the hydraulic motor also adopts an axial plunger hydraulic motor, but this is only One of the modes of the hydraulic motor may also be in other structural forms in practical applications.

[0046] from Figure 9 It can be seen in the figure that the inner cylinder of the rear-stage axial flow fan on the right adopts a conical cylinder, and its outer shell is used as a diffuser cylinder or as a part of the diffuser cylinder, and the connecting oil pipe of the hydraulic motor is at the bottom. direction.

[0047] see Figure 10 , is a schematic diagram of the supporting structure of the liquid-driven fan and the hydraulic station of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com