A machining workshop layout design method and system based on a design structure matrix

A technology for designing structure matrix and processing workshop, applied in the field of automobile workshop layout design method and system based on design structure matrix, can solve problems such as low reliability, lack of flexible production line planning and layout ideas, and difficulty in updating new models, and achieve reliable Effects of Judgment and Choice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

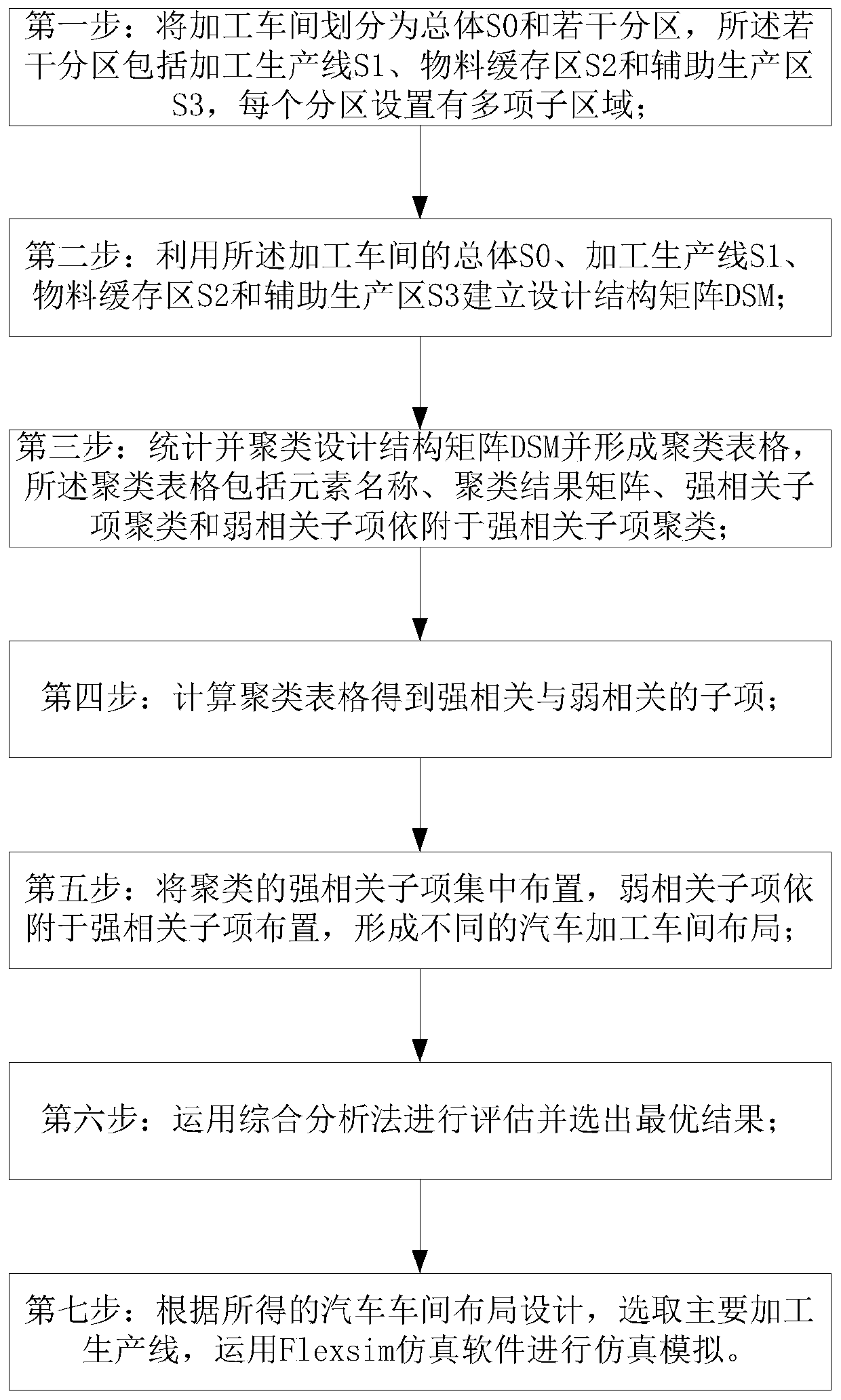

[0085] Such as figure 1 As shown, the method for designing the layout of a processing workshop based on the design structure matrix provided in this embodiment includes the following steps:

[0086] Step 1: Divide the processing workshop into an overall S0 and several partitions, the several partitions include the processing production line S1, the material buffer area S2 and the auxiliary production area S3, and each partition is provided with multiple sub-areas;

[0087] The second step: use the overall S0 of the processing workshop, the processing production line S1, the material buffer area S2 and the auxiliary production area S3 to establish a design structure matrix DSM, the design structure matrix DSM is a number of independent elements along the matrix diagonal The N×N square matrix that is arranged, if there is information transmission between matrix elements, it is marked as 1; if there is no information transmission between matrix elements, it is marked as 0;

[00...

Embodiment 2

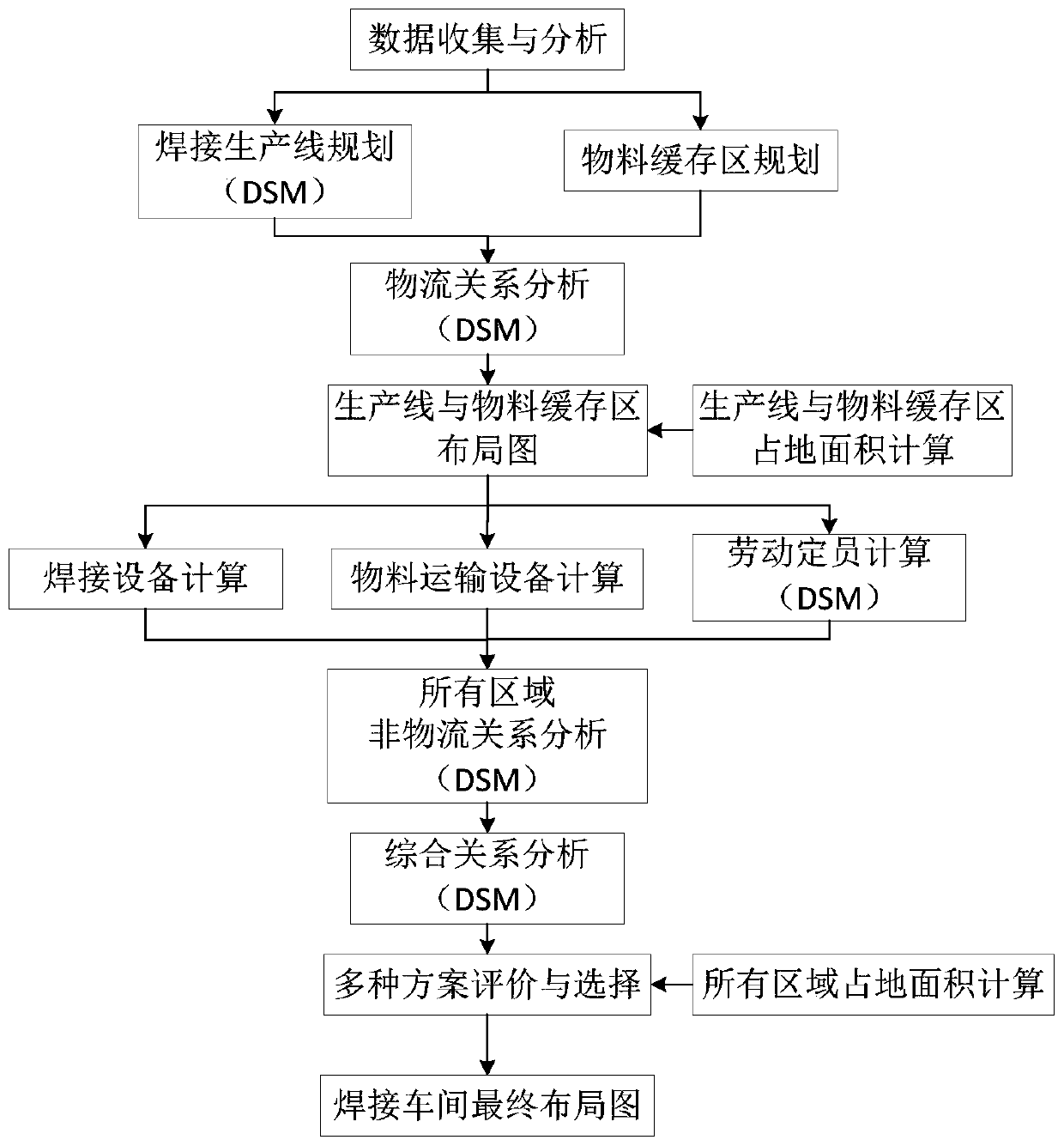

[0101] Below in conjunction with accompanying drawing and specific implementation case, the layout of automobile welding workshop is designed to further illustrate the present invention, as figure 2 As shown, the method for designing the layout of an automobile welding workshop based on the design structure matrix provided in this embodiment has the following steps:

[0102] The first step: Based on the traditional welding process expression, sort out and summarize the general process of automobile welding. The automobile welding is divided into an overall S0 and several sub-areas, the several sub-areas include welding production line S1, material buffer area S2 and auxiliary production area S3, and each welding sub-area can be further decomposed into multiple sub-areas. Before designing and planning the automobile welding workshop, conduct a feasibility analysis on the production plan of the entire factory. Research and determine the production models of the welding worksho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com