A method for predicting the axle temperature by adopting layered multivariate stepwise regression analysis

A step-by-step regression and prediction equation technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as sensor interference, shaft temperature detection system defects, and inability to collect shaft temperature information correctly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

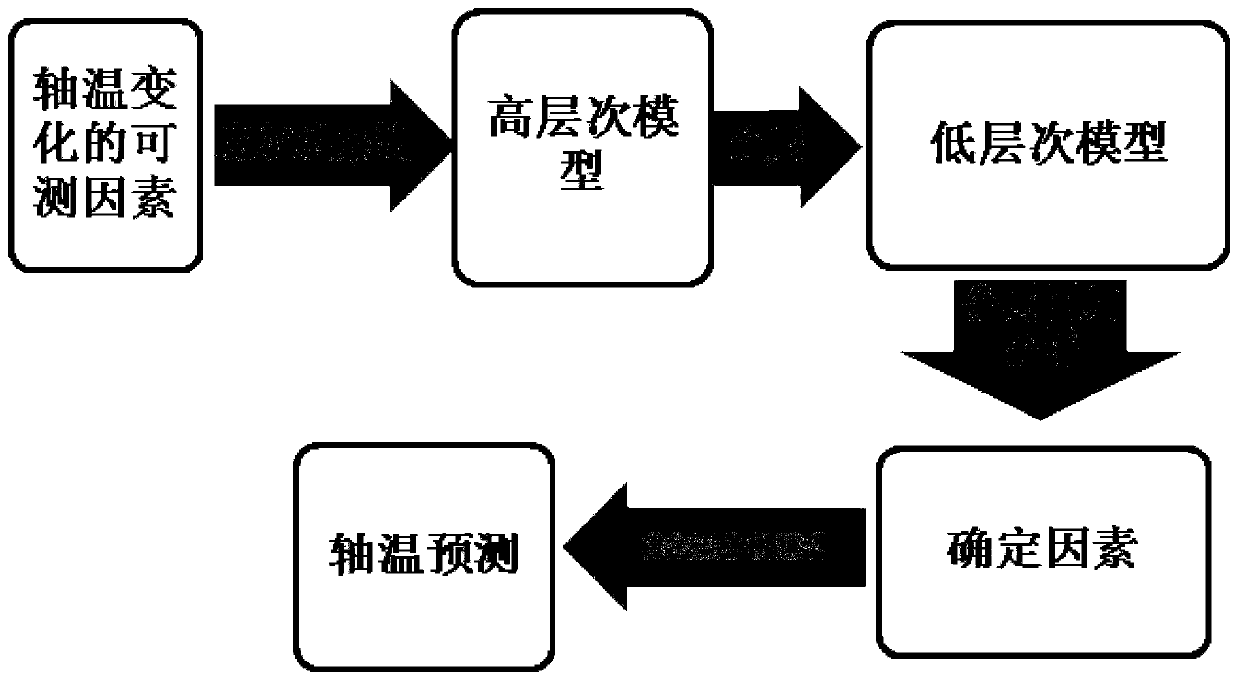

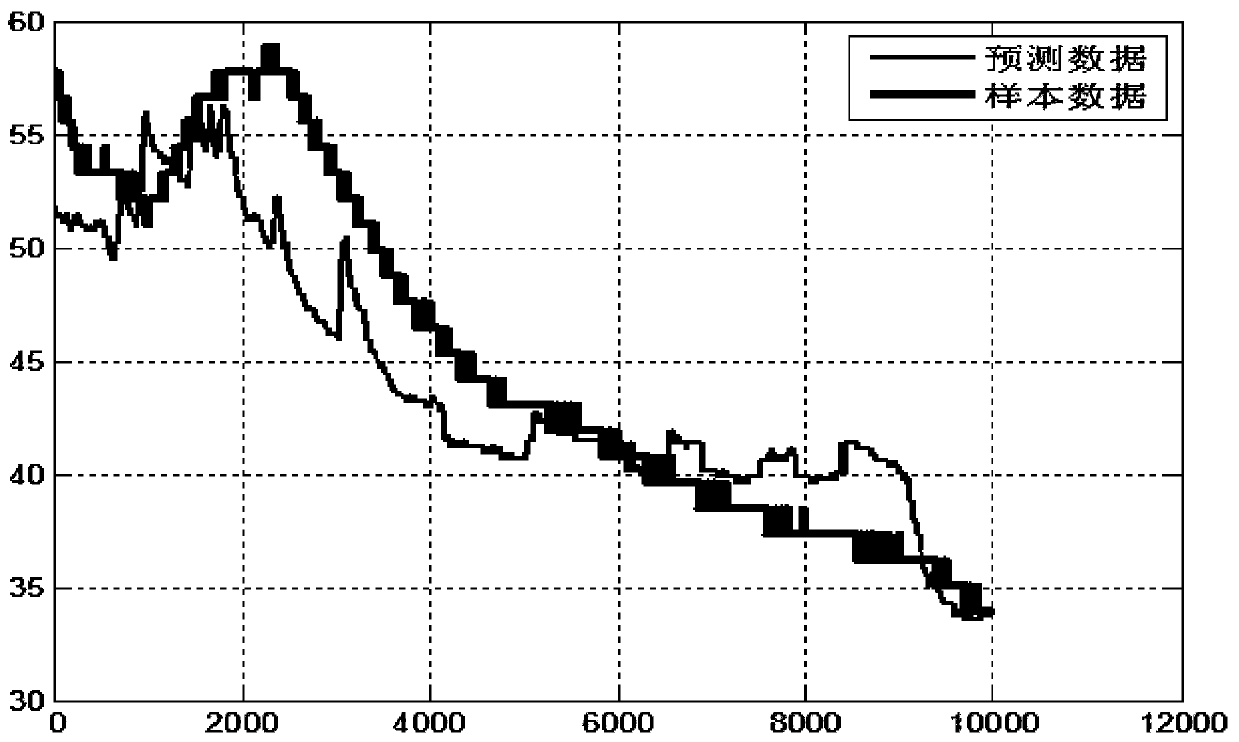

[0047] see Figure 1-2 , in an embodiment of the present invention, a method for predicting shaft temperature using hierarchical multiple stepwise regression analysis is characterized in that it includes the following steps:

[0048] (1) Data preprocessing: For the axle temperature collected by the sensor and the related data of the factors affecting its change, due to the existence of vacant values and data redundancy, it is necessary to preprocess the data. For the data in the data collection interval For the vacant value, the nearest interpolation method is used, that is, the previous value of the vacant value is used to supplement the vacant value. At the same time, all data need to be "standardized" to establish a relative coefficient matrix;

[0049] Among them, the relevant data of the factors that affect its change are several factors that are related to the shaft temperature through the Pearson coefficient. Specifically, in this embodiment, as a preference, the rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com