A green supply chain collaborative design and optimization system and method

A supply chain collaboration and supply chain technology, applied in the field of manufacturing, can solve the problems of difficulty in setting index weights, lack of effective analysis of results, and unintuitive display of design results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

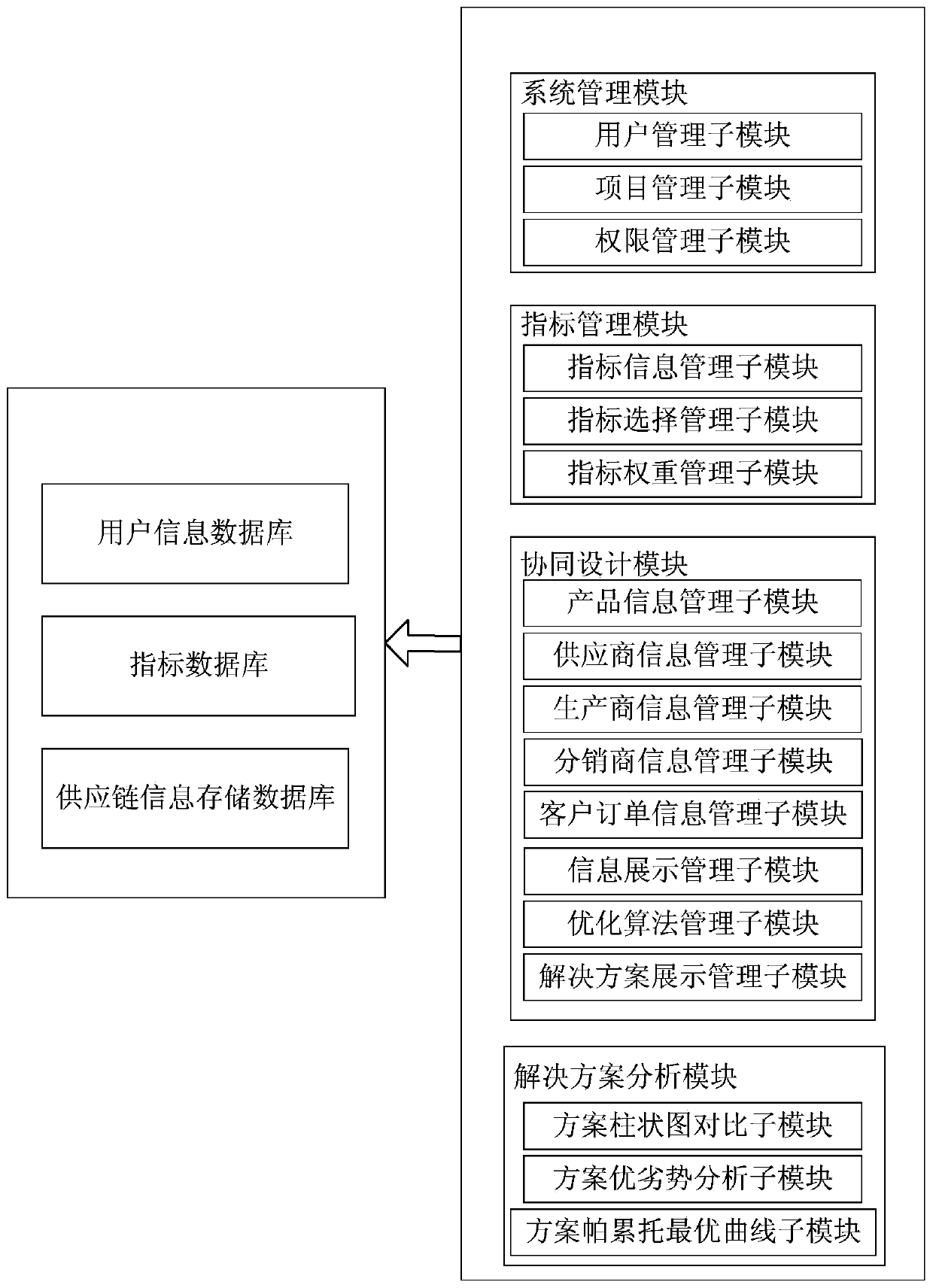

[0048] In this embodiment, a green supply chain collaborative design and optimization system, such as figure 1 As shown, it includes user information database, indicator database, supply chain information storage database, system management module, indicator management module, collaborative design module and solution analysis module; user information database, indicator database and supply chain information storage database can be stored in the remote The server runs, and it can also run on the local client. The system management module, index management module, collaborative design module and solution analysis module all run on the local client.

[0049] The system manag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com