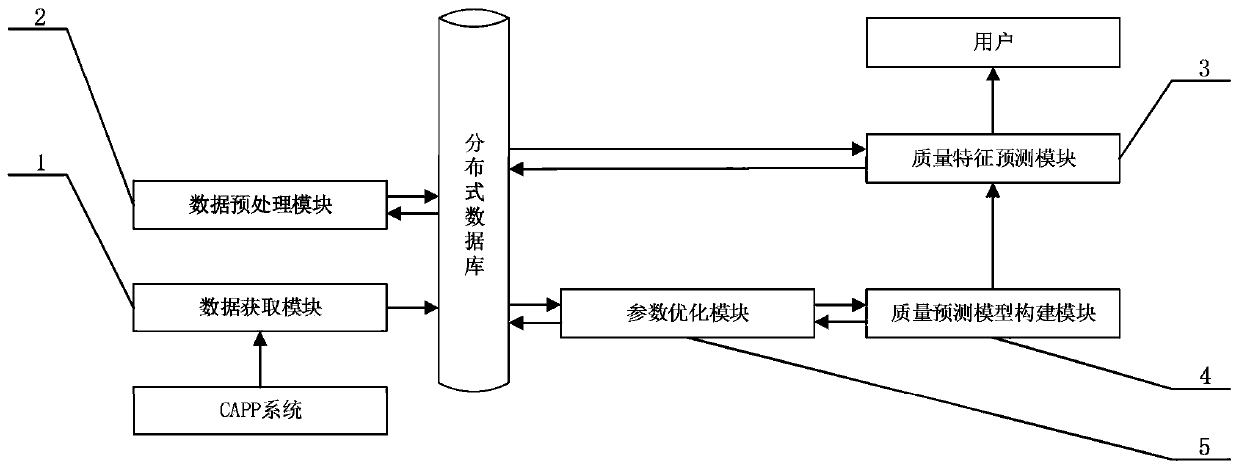

A manufacturing and assembling product quality prediction method based on a parallel long-short-term memory network

A long-short-term memory and product quality technology, applied in manufacturing computing systems, neural learning methods, biological neural network models, etc., can solve problems such as inability to accurately predict product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

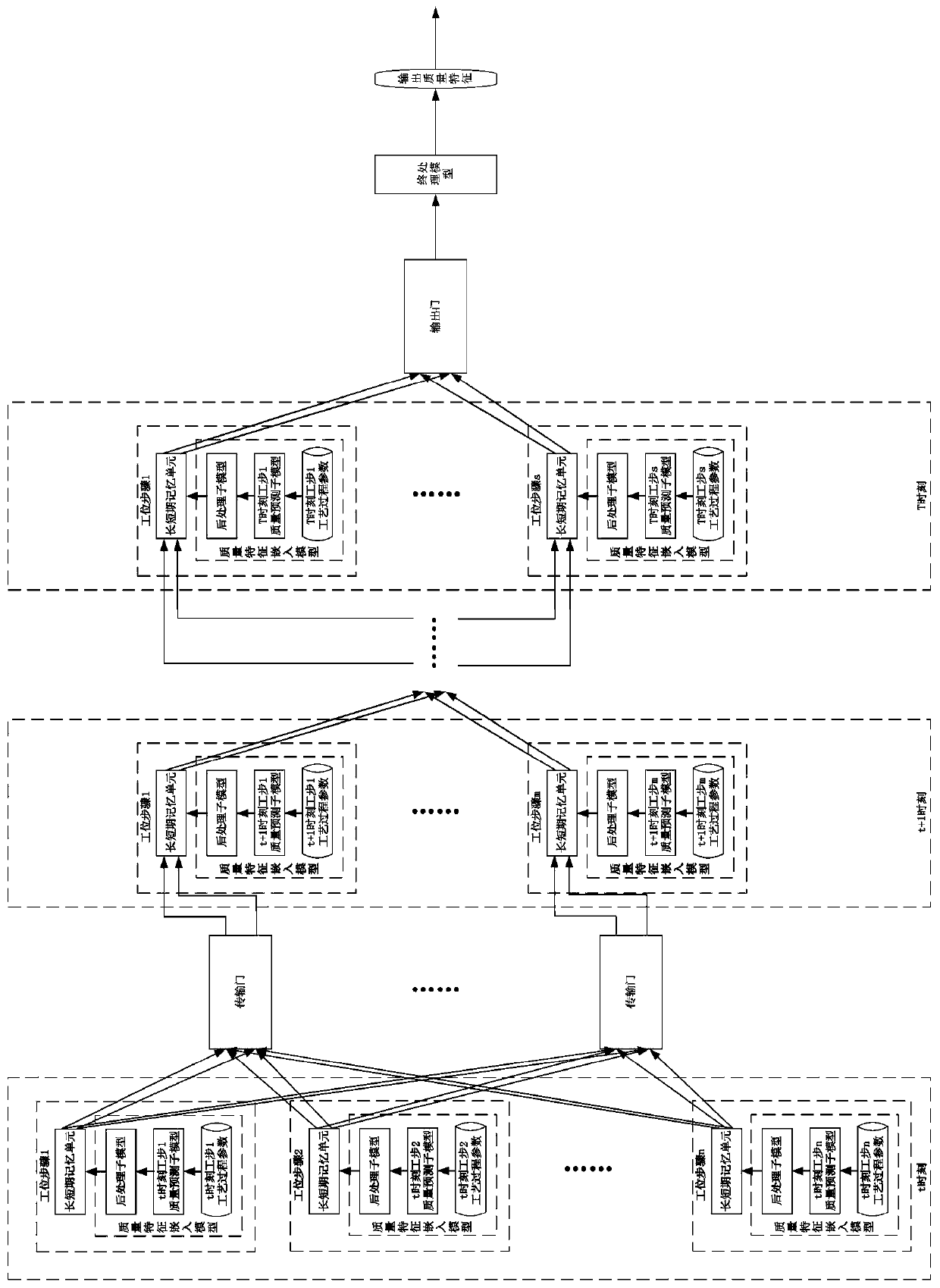

[0083] The present invention will be further described below in conjunction with drawings and embodiments.

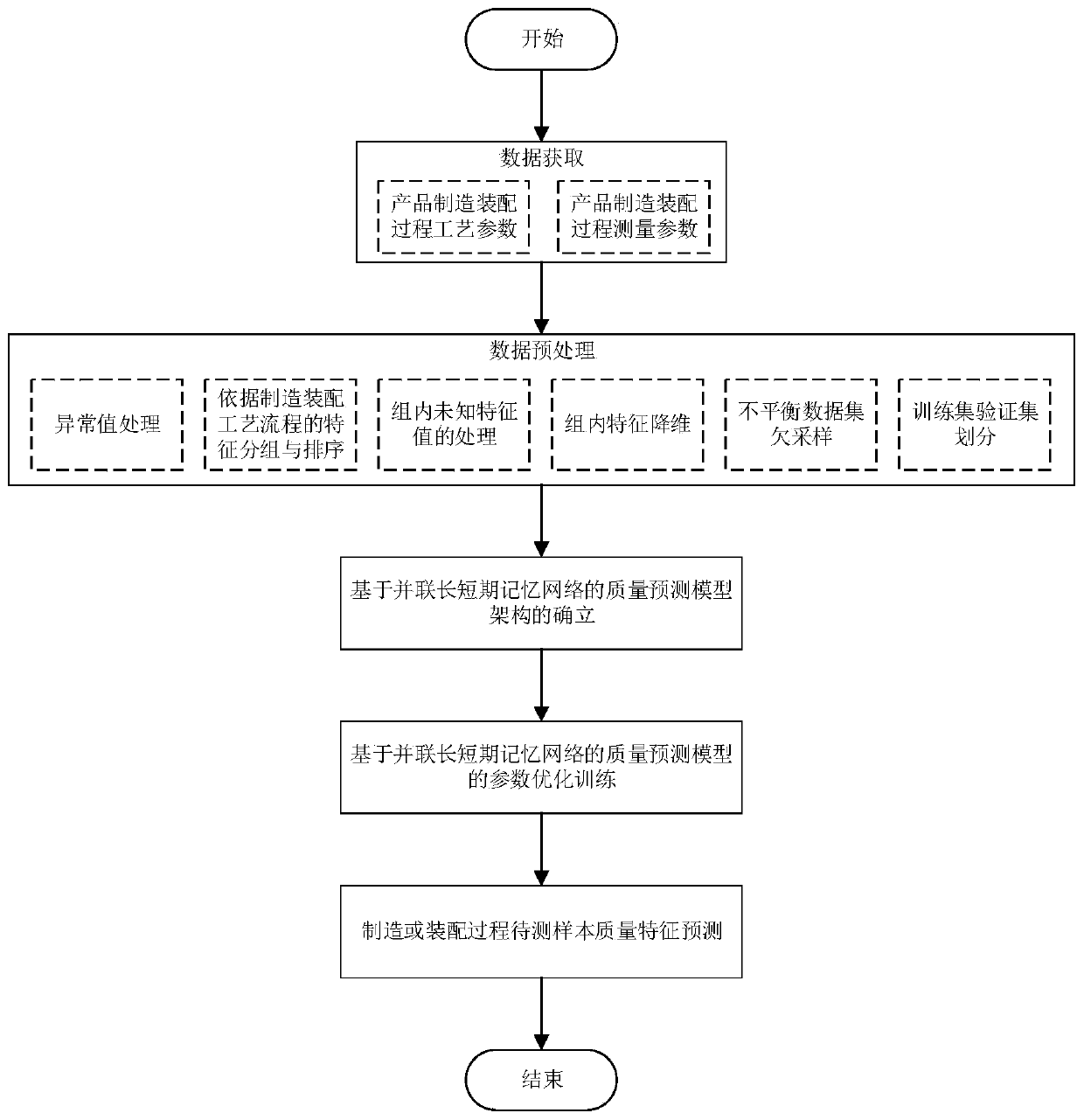

[0084] Such as figure 2 Shown, embodiment of the present invention and concrete implementation process thereof are as follows:

[0085] Step 1. Data Acquisition

[0086] The process parameter data in each station step in the rocket shell manufacturing and assembly process is obtained through multiple sensors as input characteristic data, including the process parameters and measurement parameters of each station step in the rocket shell component manufacturing or the entire assembly process. The input characteristics of each station step such as: manufacturing process: cutting speed, feed rate, depth of cut, spindle speed, workpiece speed, manufacturing time, back cutting amount, feed times, eccentricity, blank material type, tool material Category, geometric angle of the tool, fixture category number, cutting fluid category, measurement dimensional accuracy, measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com