Gas heat value soft measurement method based on combustion system operation parameter

A technology of operating parameters and combustion systems, applied in the direction of chemical process analysis/design, etc., can solve the problems of running without gas calorific value online analyzer, interfering with the operation judgment of operators, affecting the optimal operation of combustion equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

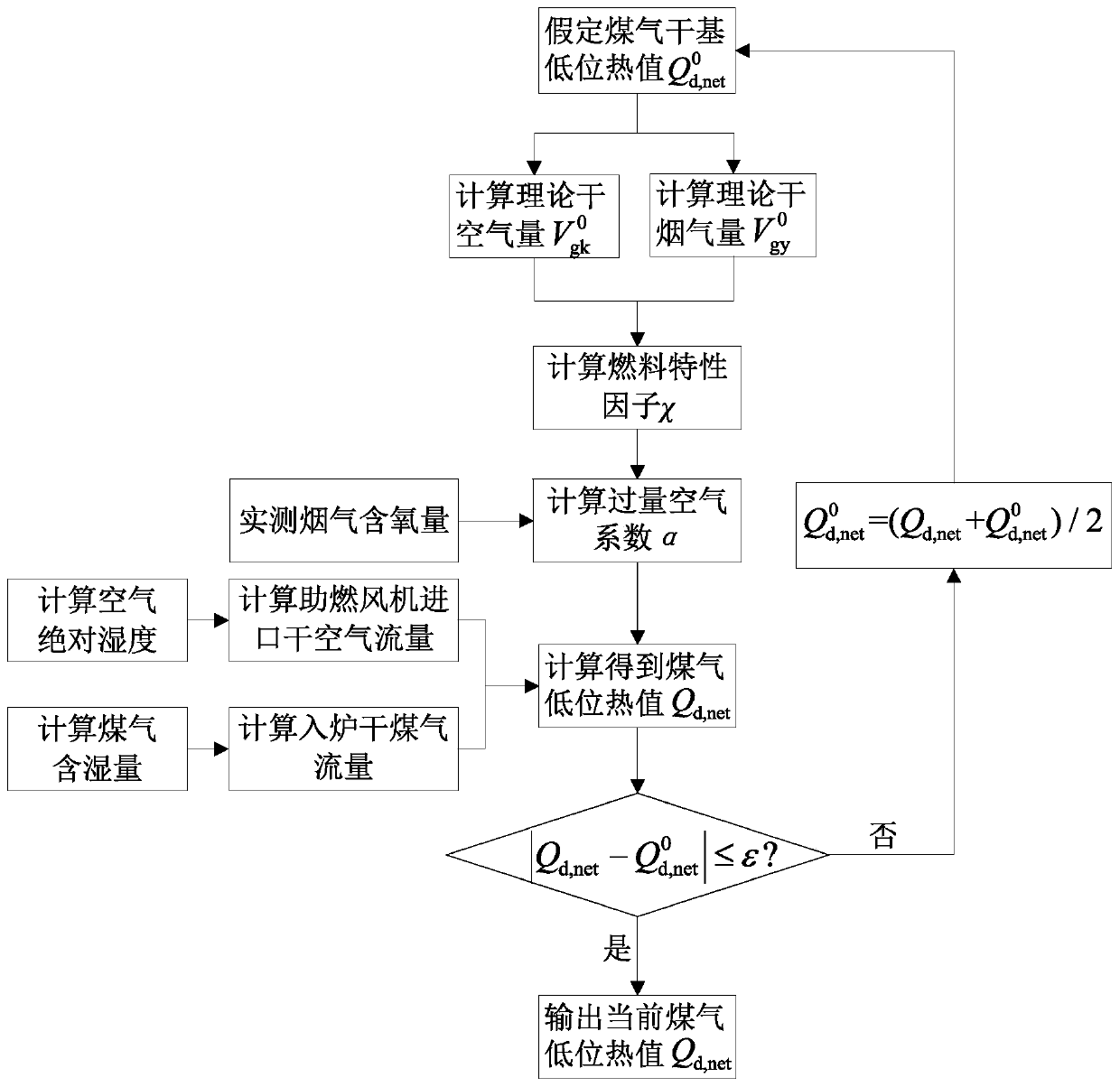

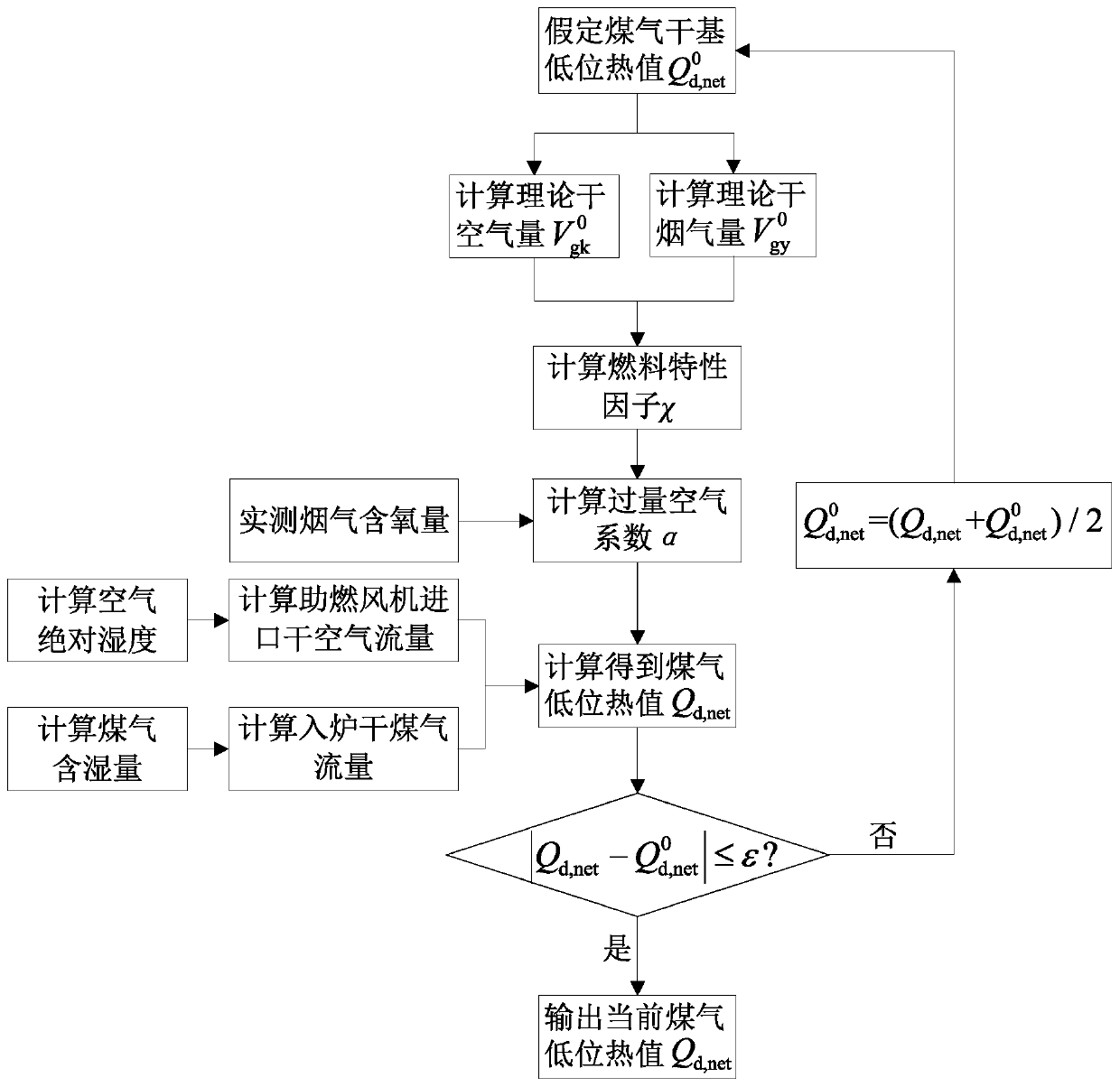

[0062] The present invention is described in further detail now in conjunction with accompanying drawing.

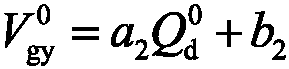

[0063] Such as figure 1 As shown, in this example, by assuming that the initial gas dry basis lower calorific value Calculation value Q of low calorific value of gas dry basis is calculated d,net , the specific soft sensor method is as follows:

[0064] Step 1. Obtain real-time data on the operating parameters of the combustion system; including but not limited to flue gas oxygen content, combustion air flow, combustion air temperature, local atmospheric pressure, combustion air pressure, gas temperature, gas pressure, and gas flow;

[0065] The combustion-supporting air flow rate, combustion-supporting air temperature and combustion-supporting air pressure are measured at the same position on the combustion-supporting air pipeline, and the measurement data at the inlet of the combustion-supporting fan are used in this embodiment.

[0066] When a gas heater is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com