Asymmetric design structure for five pair poles of minimum unit of multi-unit permanent magnet motor

A permanent magnet motor, the technology of the smallest unit, applied in the direction of magnetic circuit shape/style/structure, synchronous motor with stationary armature and rotating magnet, shape/style/structure of winding conductor, etc., to achieve smooth operation and cogging The effect of low torque and torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

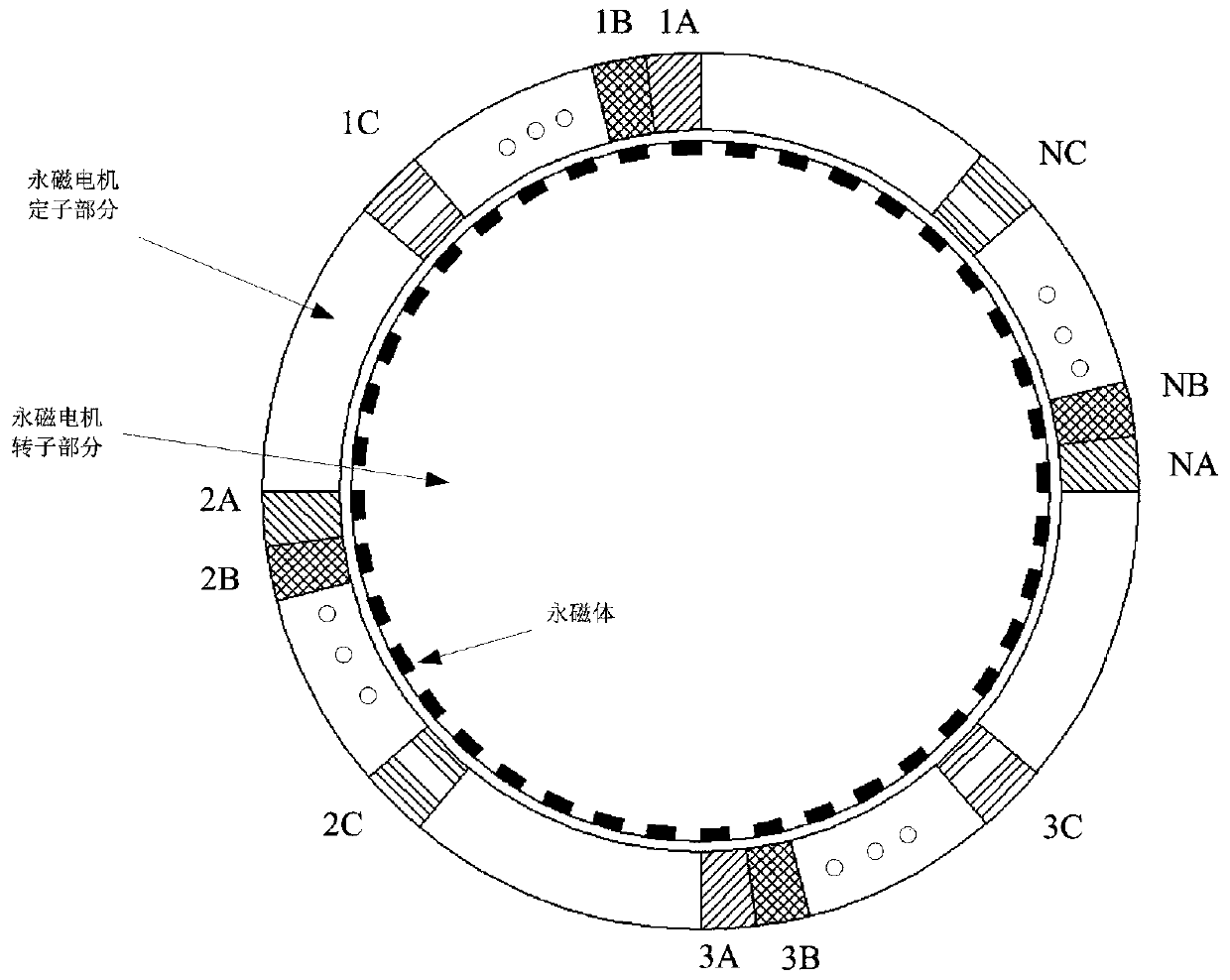

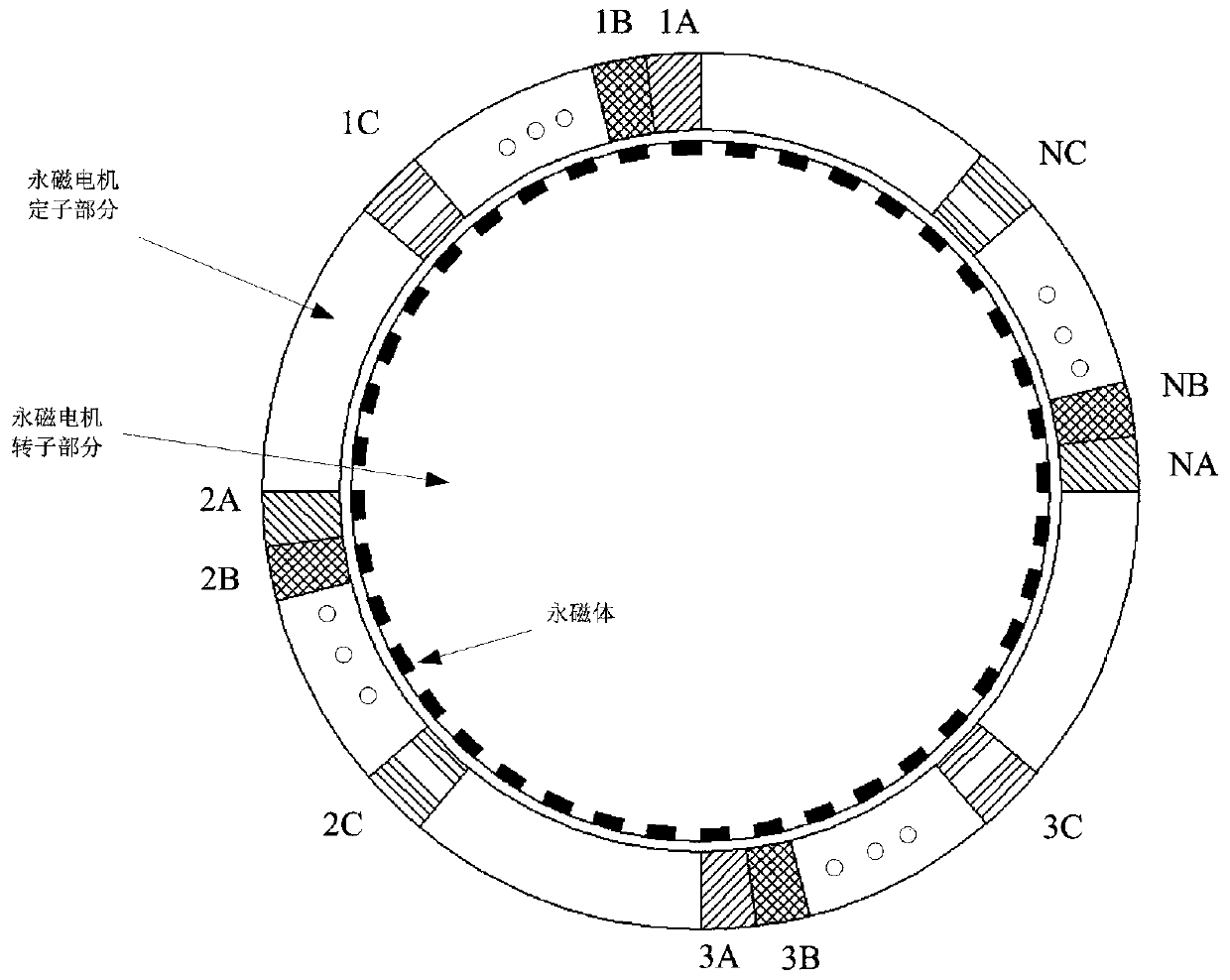

[0014] The overall structure of the multi-unit motor is as follows: figure 1 As shown, the stator winding of the multi-unit permanent magnet motor of the present invention has N independent operating units, and each independent operating unit is a 3-phase symmetrical AC winding, and the phase number m of the multi-phase multi-unit permanent magnet synchronous motor is: m= 3×N, where N is an even number greater than 3.

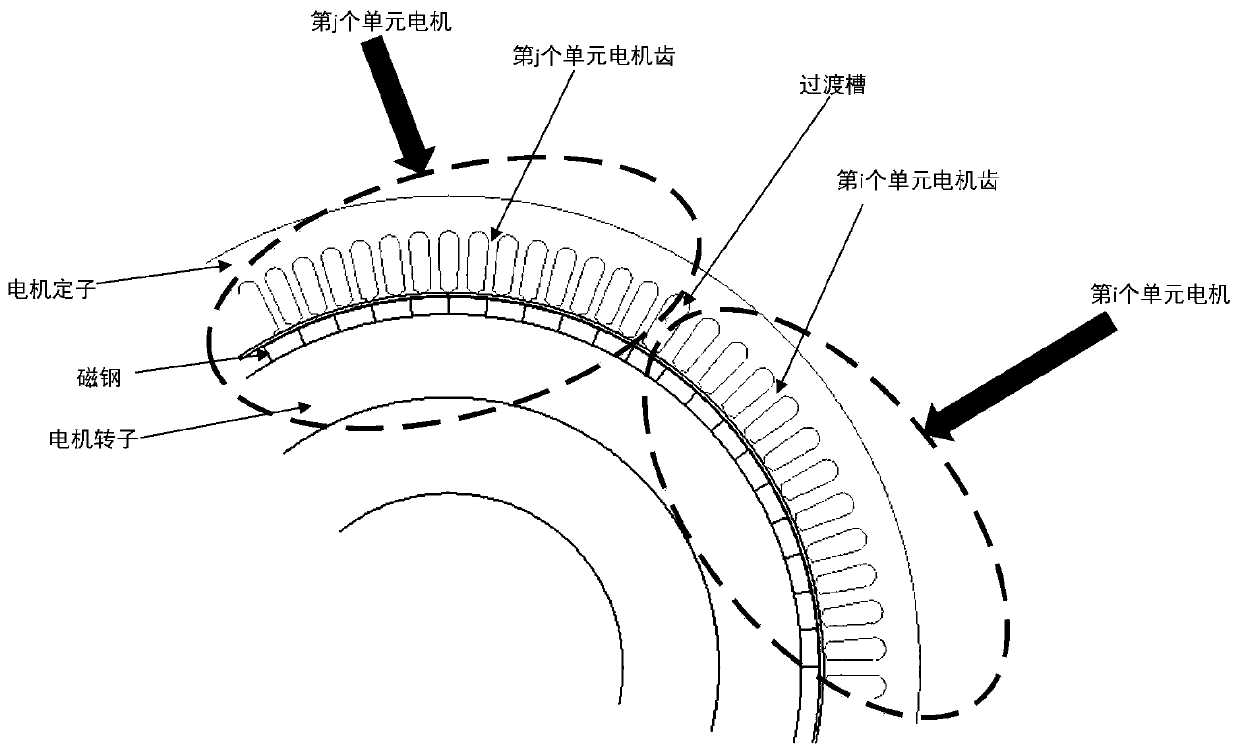

[0015] The designed multi-unit permanent magnet motor has the same number of pole pairs for each unit motor rotor and the minimum number of unit pole pairs is four (the number of poles for each unit is 10k, k is a positive integer k=1,2,3...) , the stators of two adjacent units are asymmetrical, and the number of slots is unequal. The number of slots of unit i is 12k (i is an odd number), and the number of slots of unit j is 15k (j is an even number). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com