Water cooling heat dissipation power module used for rail transit

A power module, water-cooling heat dissipation technology, applied in the direction of AC power input conversion to DC power output, output power conversion device, cooling/ventilation/heating transformation, etc., can solve the problem of weight and volume increase of permanent magnet synchronous traction drive system, system Increased design difficulty, increased heat dissipation power of the power module, etc., to achieve the effect of saving design and development investment, convenient maintenance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

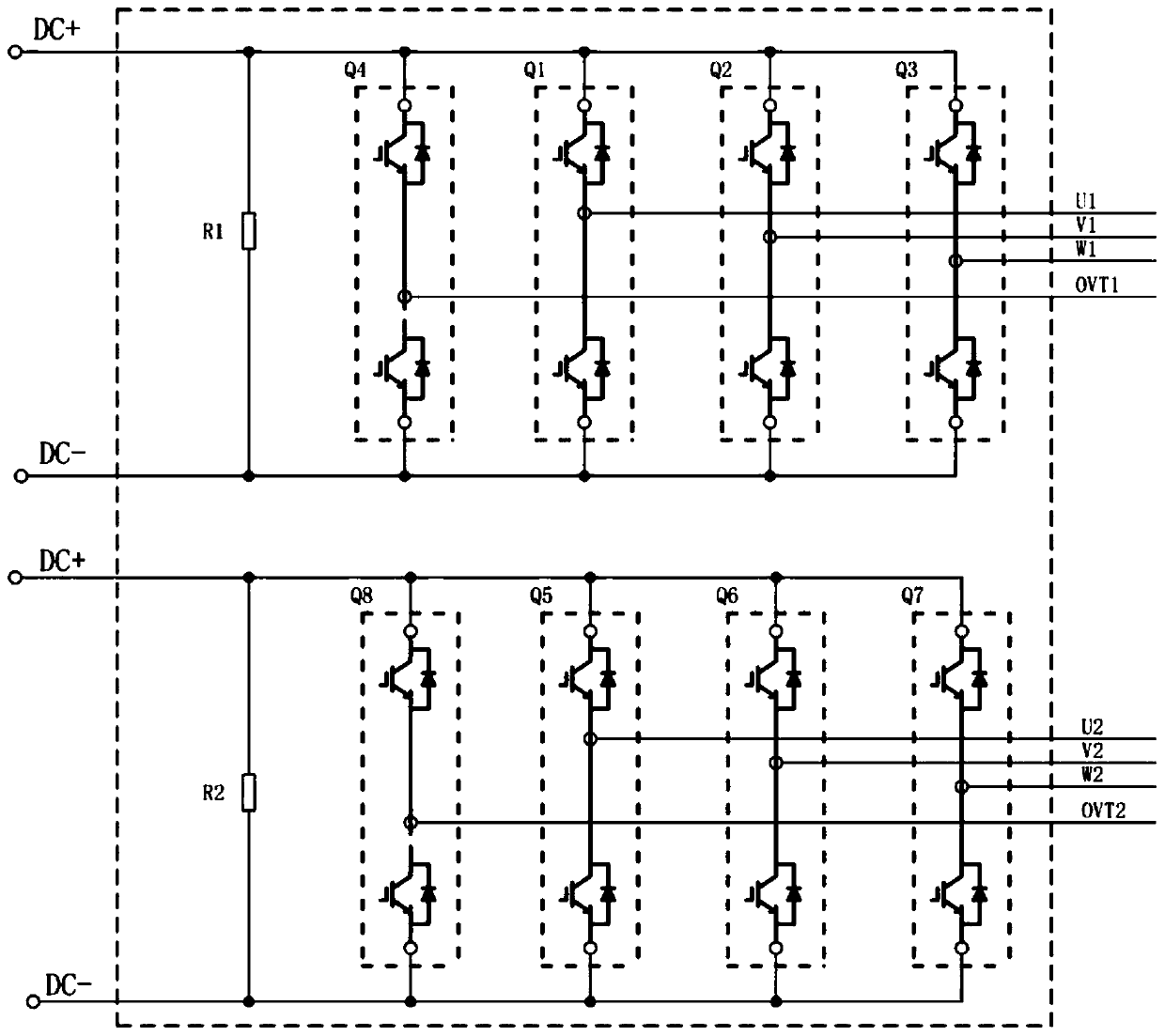

[0025] refer to figure 1 As shown, the rail transit water-cooled heat dissipation power module of this embodiment integrates two traction inverter units, and each inverter unit is composed of Q1-Q4 and Q5-Q8 respectively, wherein Q1 and Q5 are the two inverter units respectively. U-phase bridge arms, Q2 and Q6 are V-phase bridge arms, Q3 and Q7 are W-phase bridge arms, and Q4 and Q8 are chopping bridge arms. At the same time, each inverter unit integrates fixed loads R1 and R2, which simplifies the system layout.

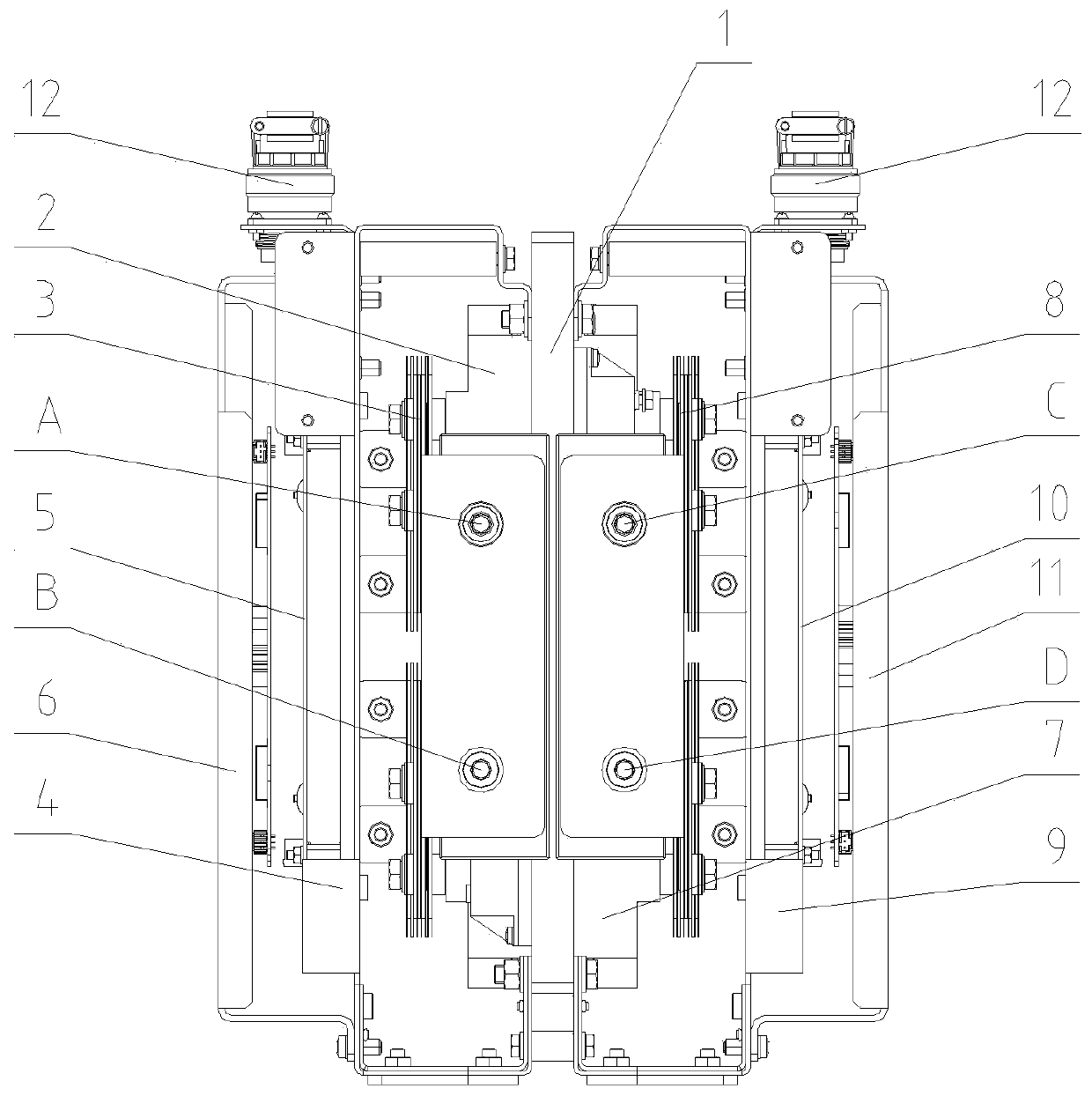

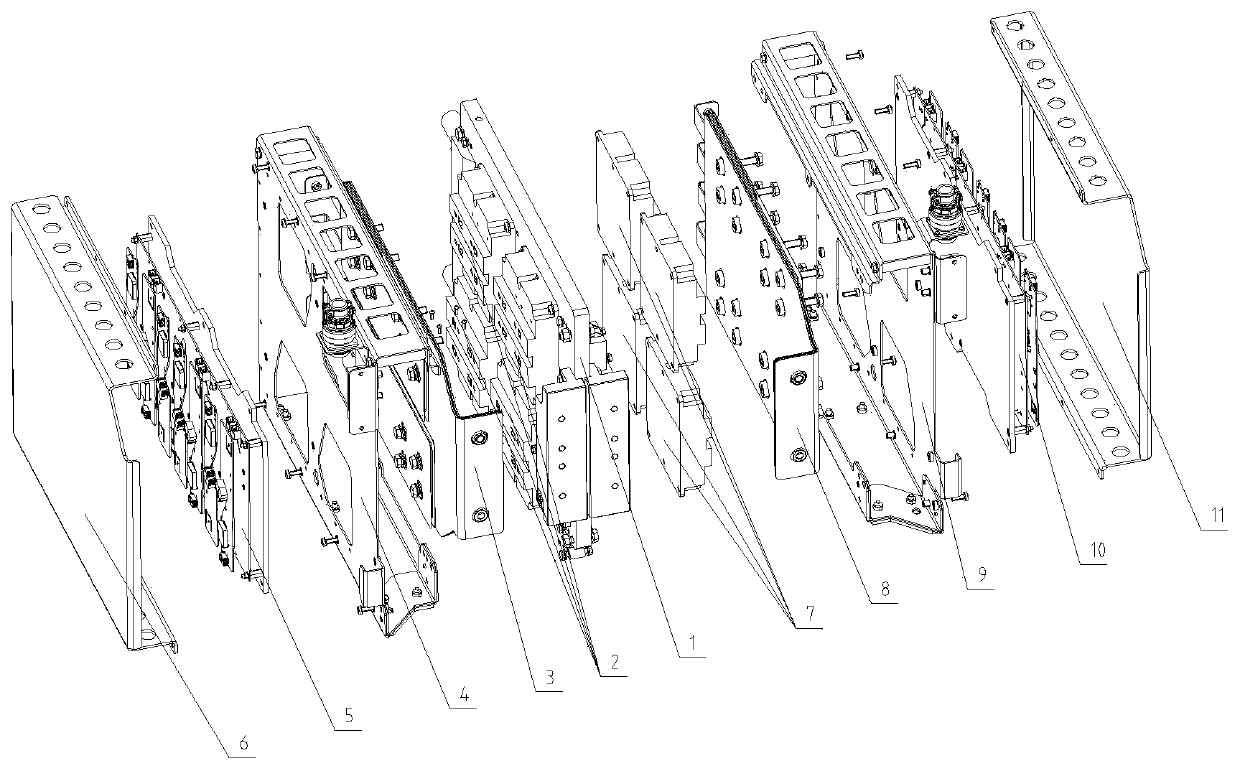

[0026] see figure 2 , image 3 , Figure 4 , the power module also includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com