Fixed-point lifting laver (Porphyra) stripping device for spherical laver culture balls

A peeling device, a technology for laver, applied in agricultural machinery and implements, applications, harvesters, etc., can solve problems such as low efficiency and uneven peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

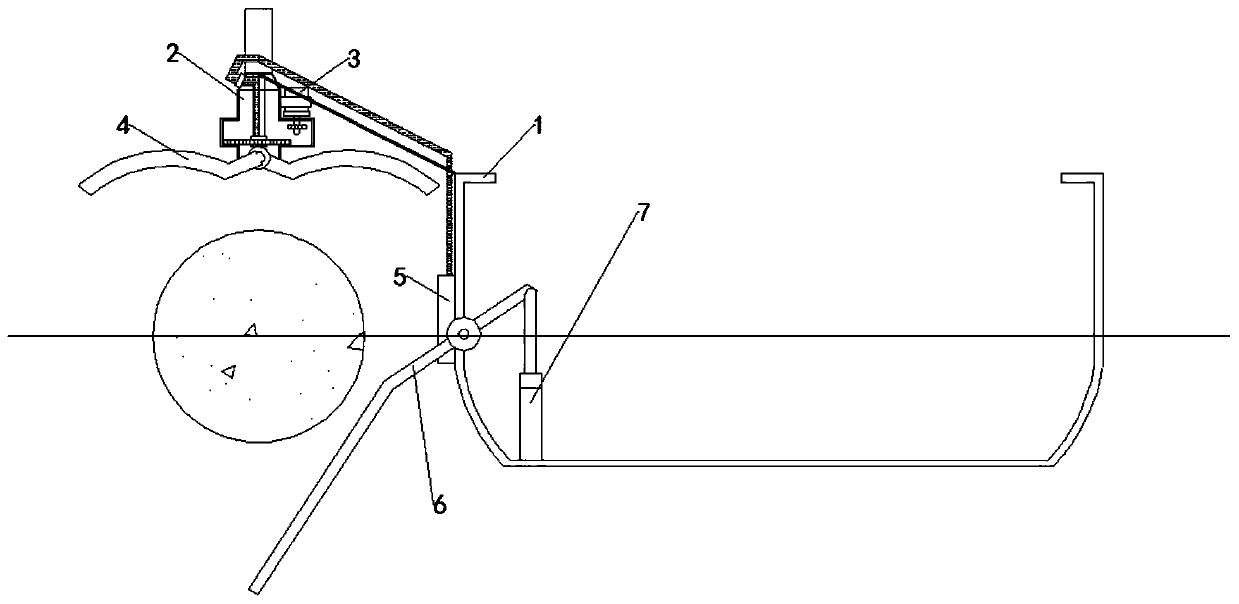

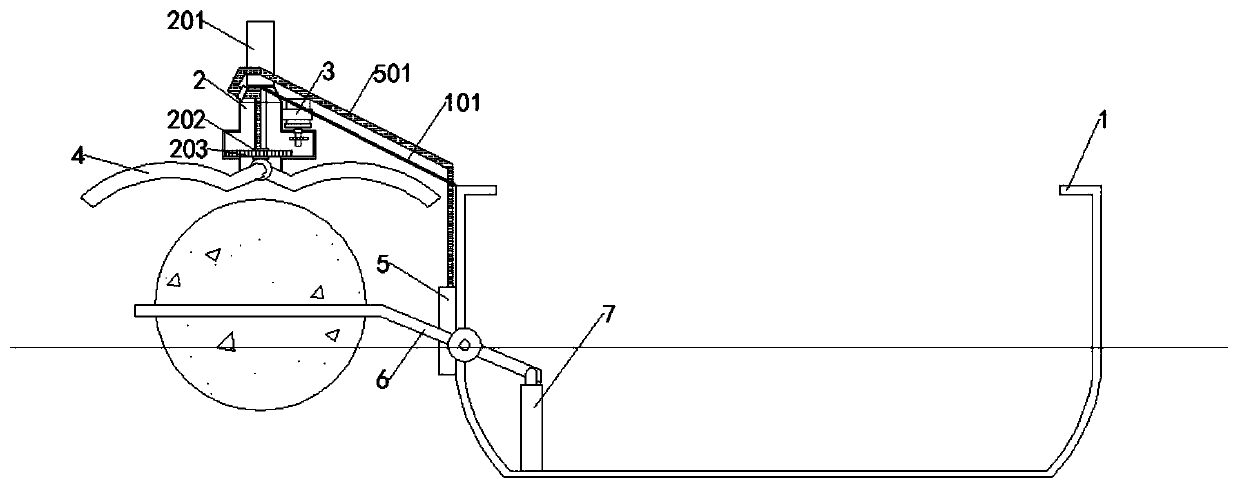

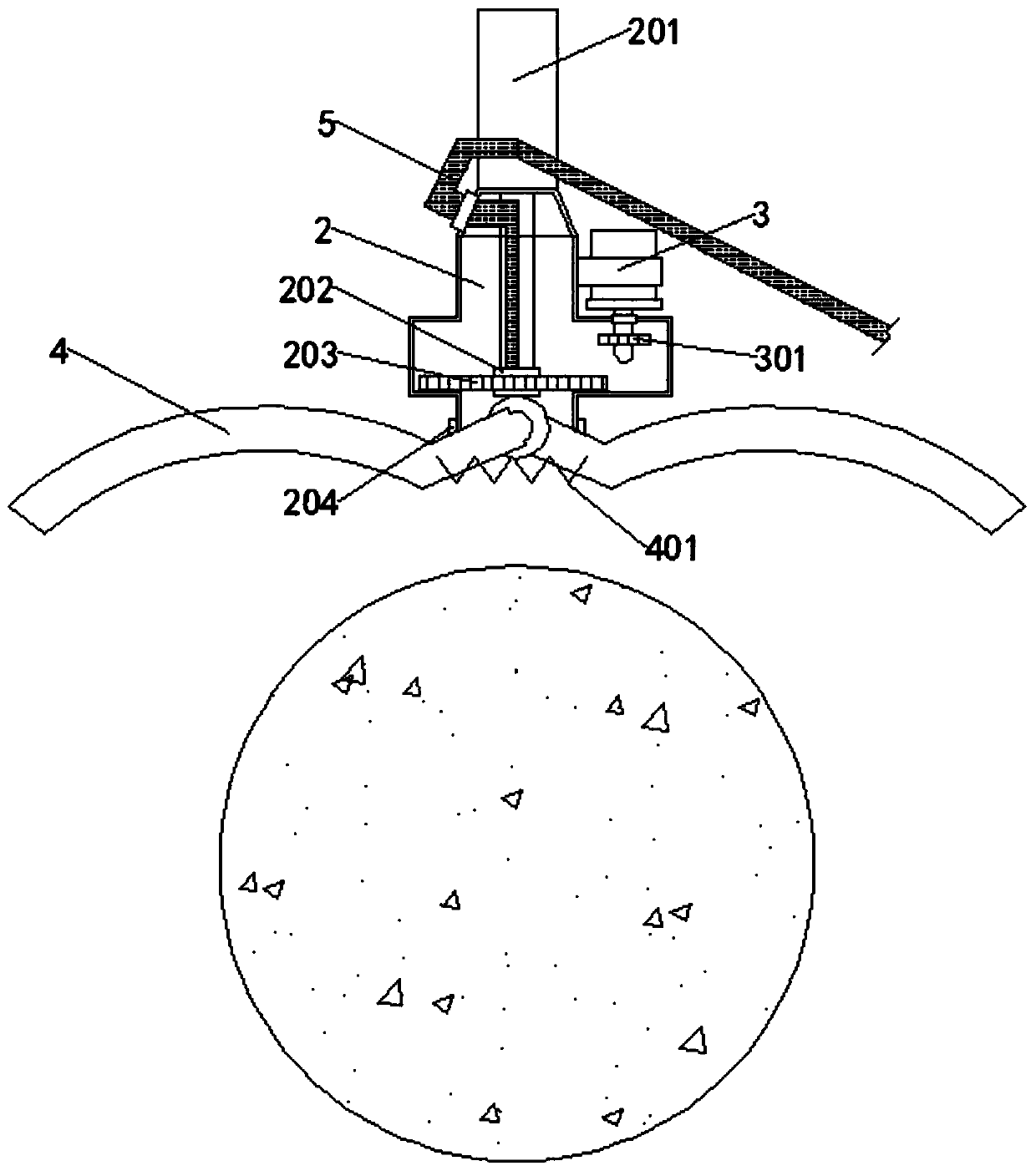

[0026] see Figures 1 to 8, in the embodiment of the present invention, including hull 1, fixed steel bar 101, stripper shell 2, hydraulic rod 1 201, bearing 202, bearing center connection point 2021, bearing outer ring 2022, gear 203, bearing 2 204, motor 3, transmission Gear 301, peeling claw 4, spring 401, water pump 5, hose 501, bracket 6, groove 601, chute 602, inclined chute 603, baffle plate 6031, filter screen 6032 and hydraulic pressure 2 7, hull 1 left The top of the side is fixedly connected with a fixed steel bar 101, and the top of the left side of the fixed steel bar 101 is fixedly connected with a stripper shell 2, and the top surface of the stripper shell 2 is clamped with a hydraulic rod one 201, and the bottom surface of the hydraulic rod one 201 is fixedly connected with a bearing 202, The left and right sides of the top surface of the bearing 202 are fixedly connected with the bearing center connection point 2021, and the bearing 202 is connected with the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com