A cosmetic bottle with its own pressure

A self-contained pressure cosmetic bottle technology, applied in the packaging of cosmetics, cosmetic powder containers, toiletry containers, etc., can solve the problems that the cosmetic bottle cannot be fully used, is not connected to the outside world, and the working efficiency of the pressure pump is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

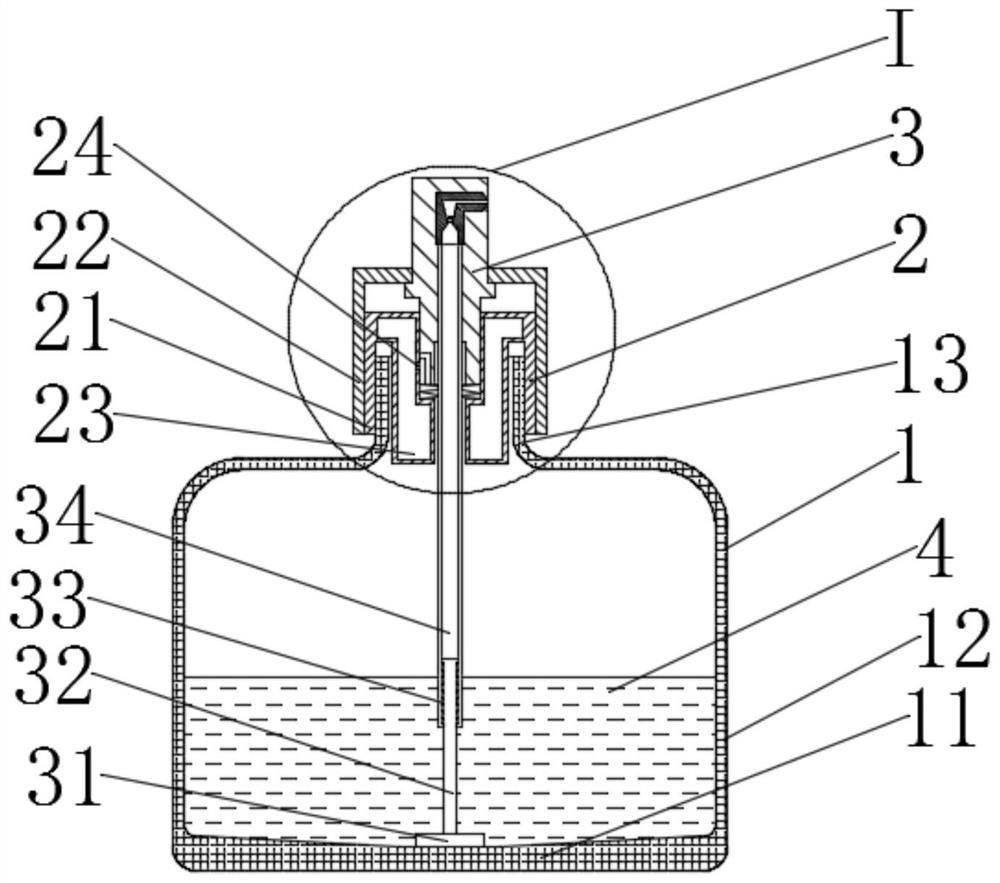

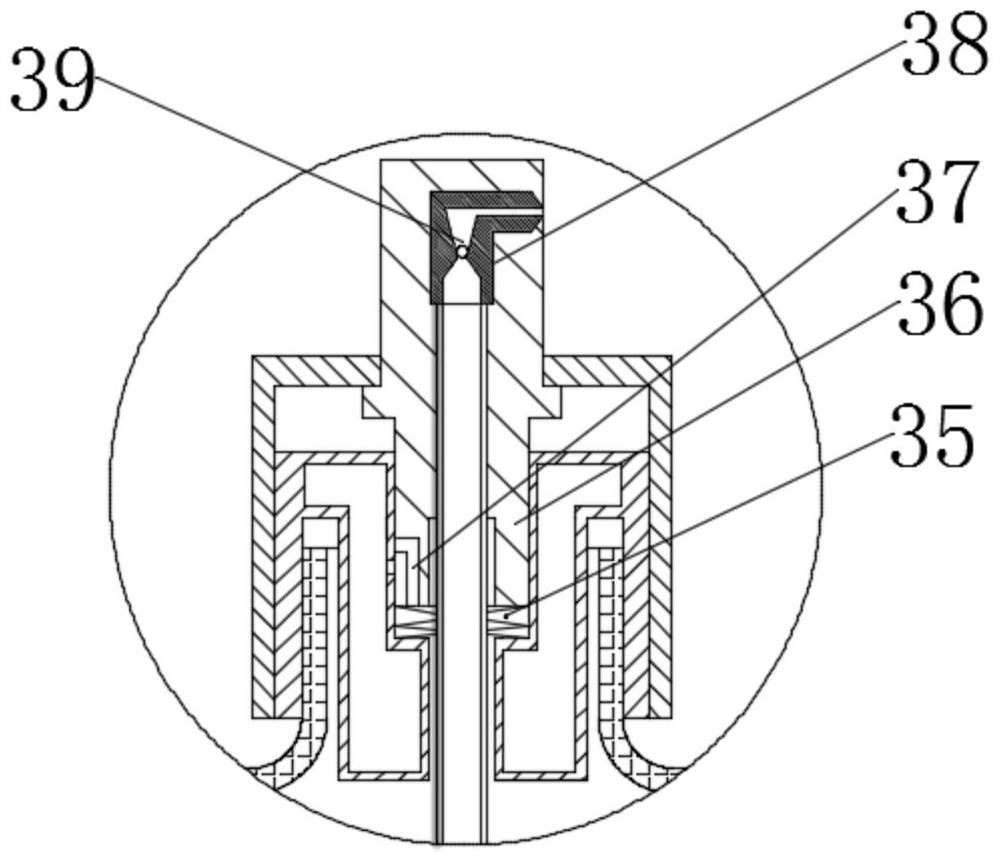

[0023] see Figure 1-2 , a cosmetic bottle with its own pressure, comprising a bottle body 1, a bottle cap 2 and a spray mechanism 3; the bottle cap 2 is fixed on the bottle body 1 through threaded connection; the spray mechanism 3 is fixed on the bottle cap 2 by a spring internal;

[0024] The bottle body 1 includes a bottle bottom 11, a bottle body 12 and a bottleneck 13; the bottle body 1 is made of glass; the bottle bottom 1 and the bottle body 2 enclose a cosmetic storage cavity; the upper end of the bottle bottom 11 is provided with There is a groove; the groove is tapered to prevent residual cosmetics in the bottle; the bottle mouth 13 is provided with threads for installing the bottle cap 2;

[0025] The bottle cap 2 is divided into an inner bottle cap 21 and an outer bottle cap 22; the inner bottle cap 21 is provided with a pressure chamber 23; the pressure chamber 23 is filled with high-pressure nitrogen; the inside of the pressure chamber 23 is provided with a pres...

Embodiment 2

[0032] A bottled cosmetic, comprising the cosmetic bottle with self-pressure described in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com