Novel tire glue spraying machine and using method thereof

A glue-spraying machine and glue-spraying technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of uneven flow of the glue, large differences in the thickness of the sprayed layer, and weakening of the fluidity of the glue. The effect of uniform distribution of glue quantity, uniform coating thickness and precise flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

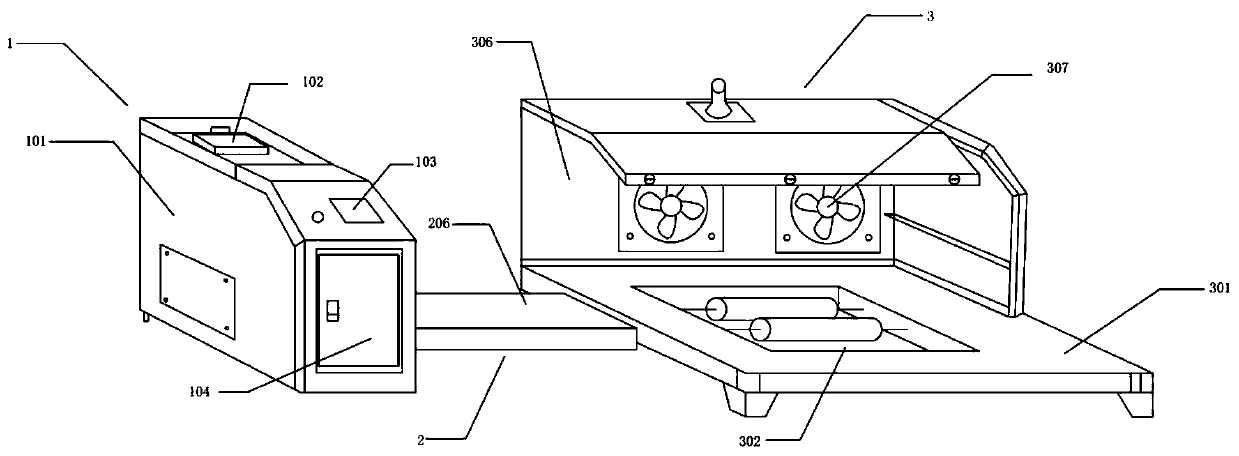

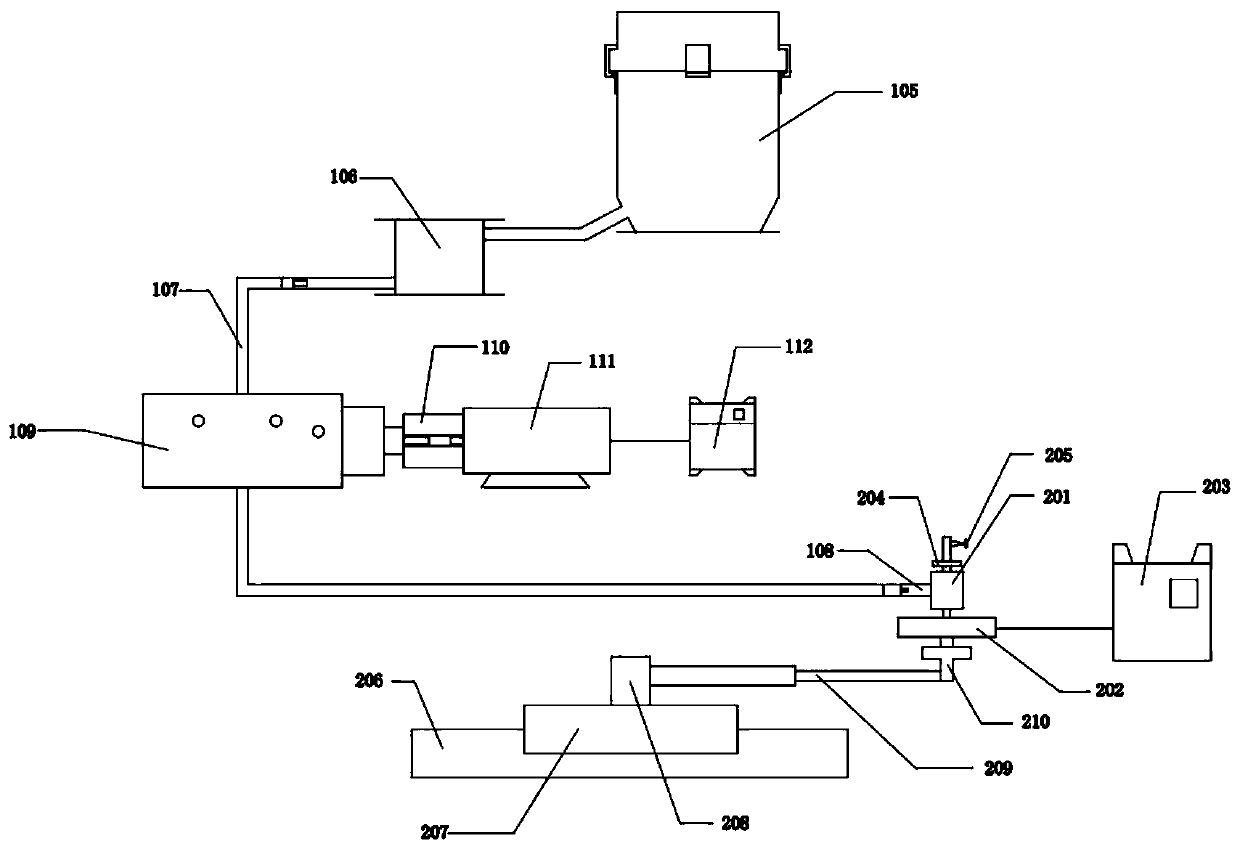

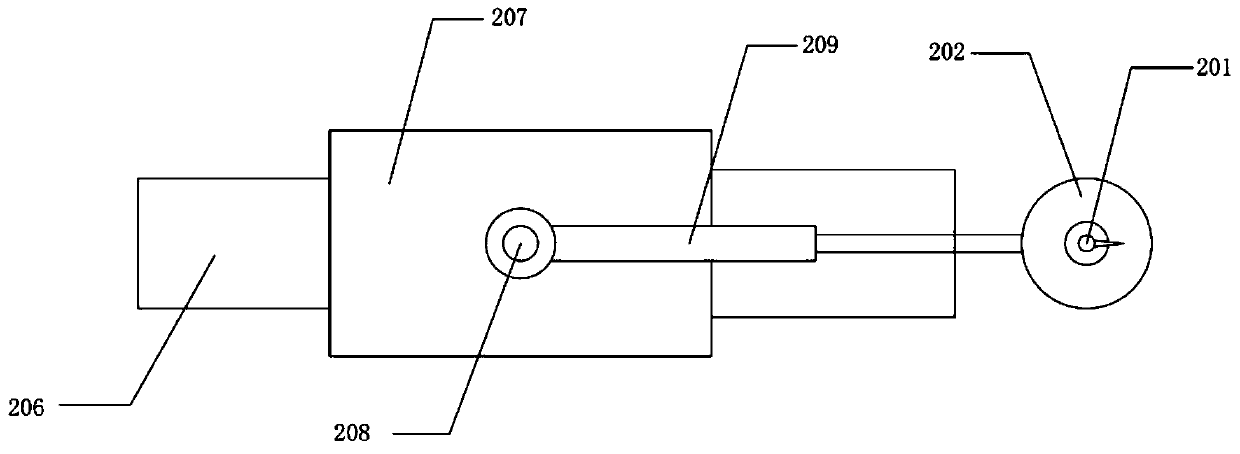

[0036] see Figure 1-8As shown, a new type of tire glue spraying machine includes a chassis mechanism 1, a glue spray mechanism 2, and a worktable mechanism 3; the chassis mechanism 1 includes a box body 101, and an upper slot 102 is opened above the box body 101, The top of the upper slot 102 is equipped with an upper slot cover, the side of the casing 101 is equipped with a touch screen 103, and the inside of the touch screen 103 is equipped with a control CPU. The main slot 104 is arranged directly below the touch screen 103, and the main slot 104 The main tank cover is installed, and the staff can check and repair the internal parts of the box body 101 through the main slot hole. The inside of the cabinet 101 is equipped with a melting glue bucket 105. To realize feeding, the bottom of the melting glue barrel 105 is connected to the glue stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com