A vehicle hybrid power system adopting a planetary gear mechanism and a double-clutch module

A technology of hybrid power system and double clutch, which is applied to the layout of multiple prime movers of general power plants, power plants, vehicle components, etc., and can solve energy loss, friction surface friction coefficient reduction, and low shifting efficiency, etc. problem, to achieve the effect of improving efficiency, reducing shift loss, and reducing system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

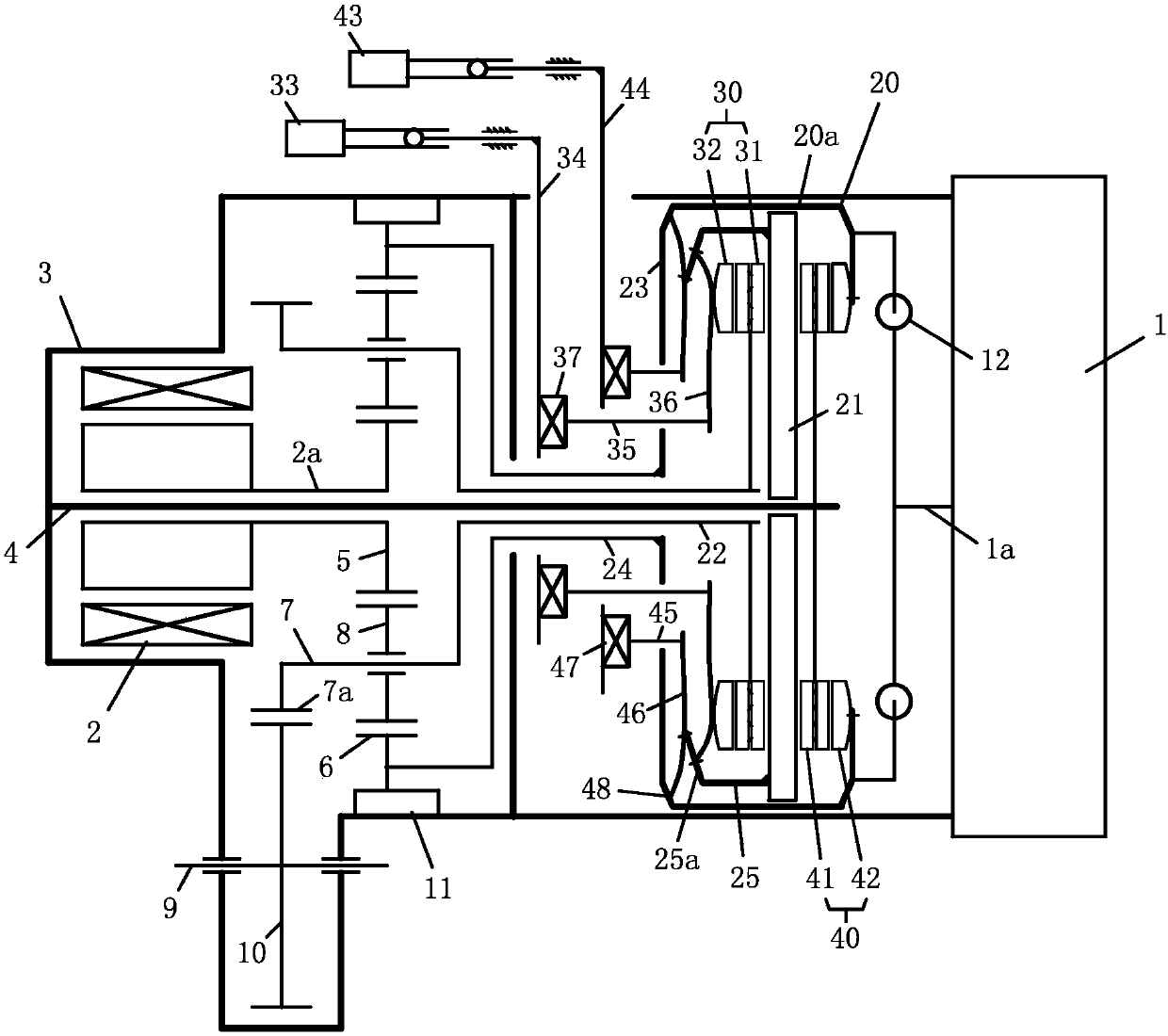

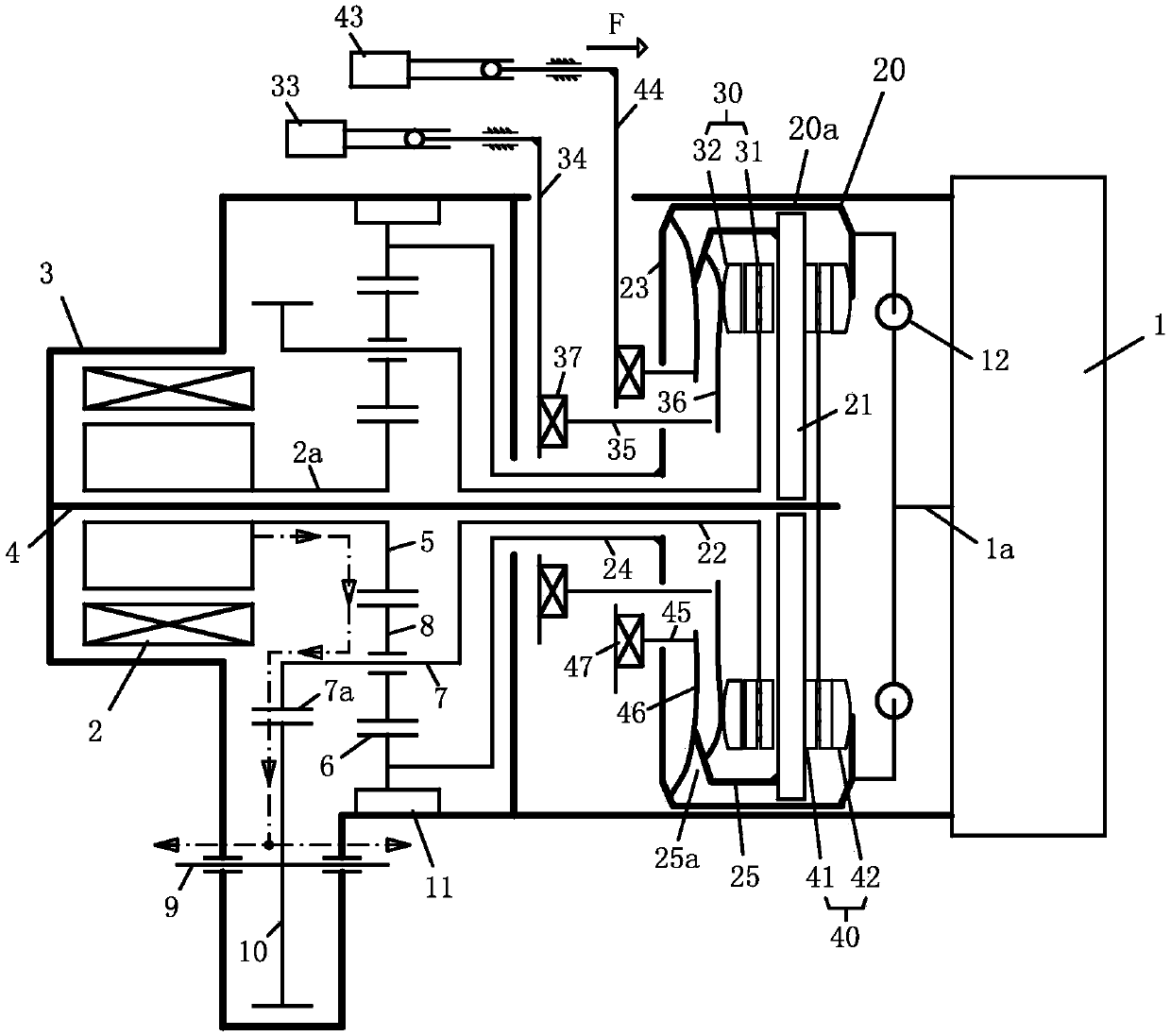

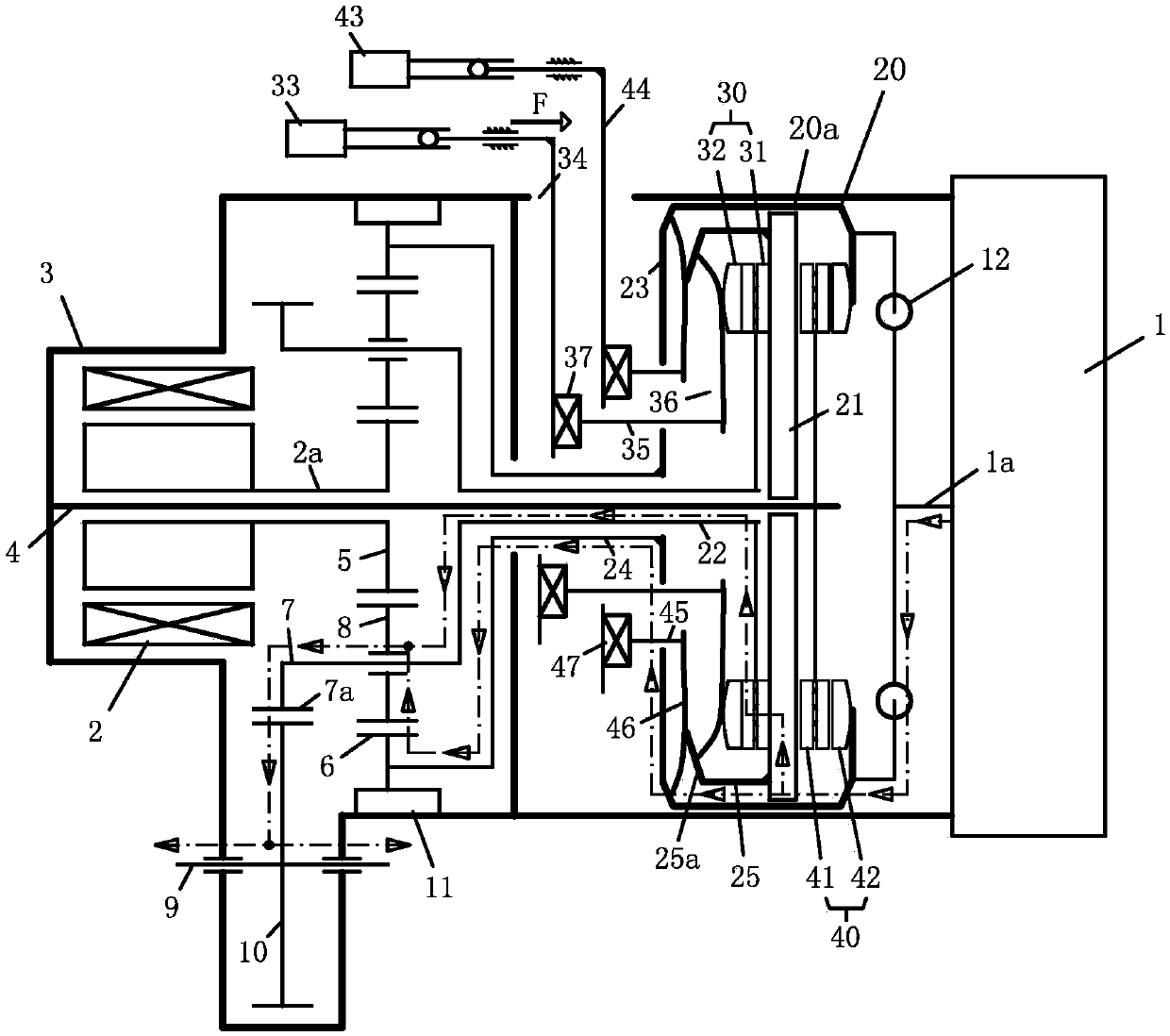

[0034] The vehicle hybrid power system of the present application will be described below with reference to the accompanying drawings.

[0035] figure 1 A vehicle hybrid power system according to a possible implementation of the present application is schematically shown, which includes two power sources, one of which is an engine 1 and the other is an electric motor 2 . The engine 1 has a motor shaft 1a, and the electric machine 2 has a motor shaft 2a. The vehicle hybrid power system also includes a transmission (power coupling device), which is arranged between the engine 1 and the motor 2, and is configured to be dynamically connected to the engine shaft 1a so as to be able to receive the output power of the engine 1 from the engine shaft 1a, and It is dynamically connected with the motor shaft 2a so as to be able to receive the output power of the motor 2 from the motor shaft 2a and transmit power to the motor 2 through the motor shaft 2a (making the motor 2 act as a gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com