Low-energy coal water slurry gasification system and coal water slurry heating method

A technology of gasification system and coal-water slurry, which is applied in the manufacture of combustible gas and petroleum industry, etc., can solve the problems of high coal consumption and oxygen consumption, high operating cost, and easy blockage of heat exchangers, etc., to reduce coal consumption and Oxygen consumption, reduce operating costs, improve the effect of active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

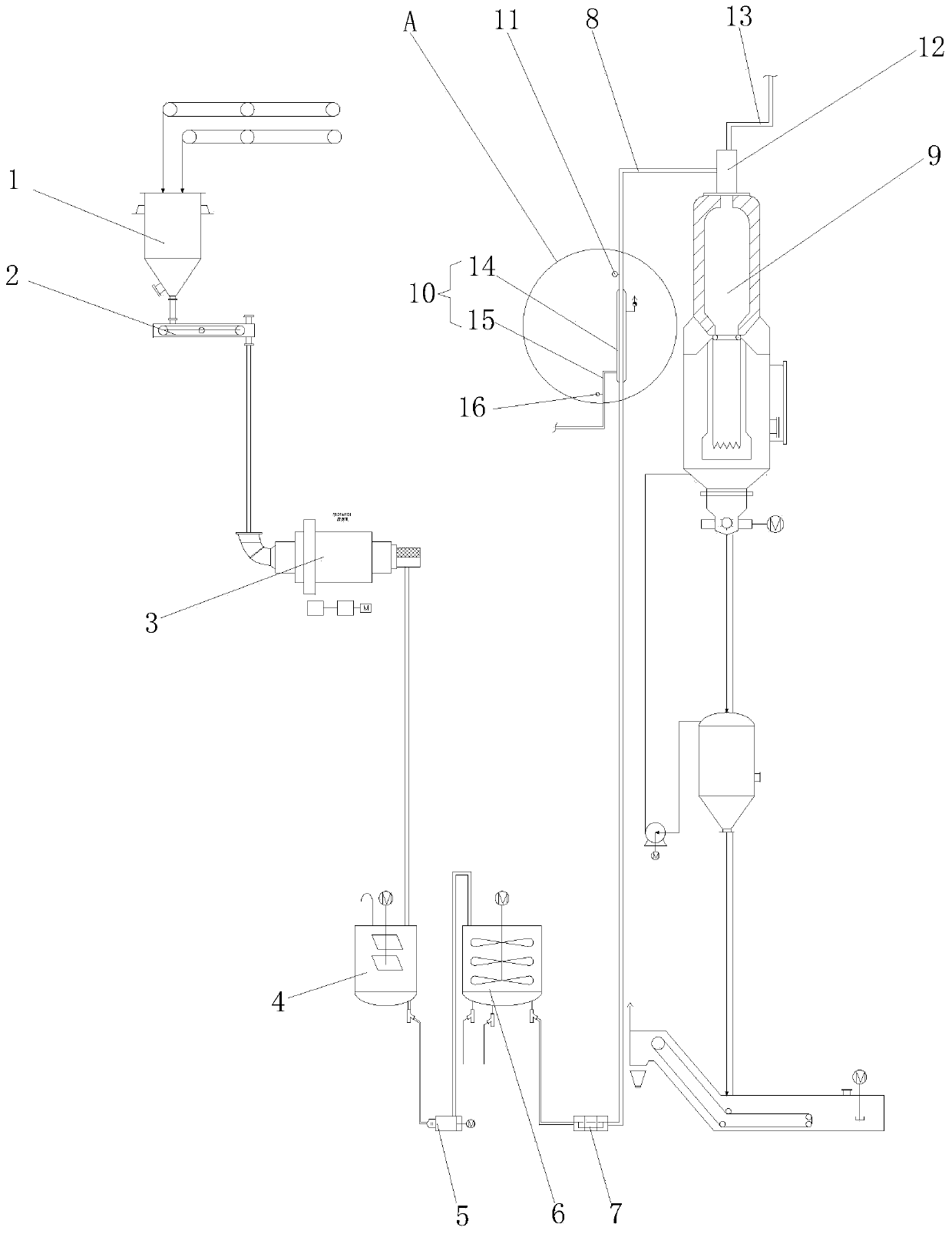

[0021] Embodiment 1 of the present invention: a low-energy-consumption coal-water slurry gasification system, comprising a coal storage hopper 1, the discharge port of the coal storage hopper 1 is connected to a coal weighing feeder 2, and the coal weighing feeder 2 is connected to The inlet of the coal mill 3 is connected, the coal mill 3 is connected to the mill discharge chute 4, the outlet of the mill discharge chute 4 is connected to the mill discharge chute pump 5, and the mill discharge chute pump 5 Connected to the coal slurry tank 6, the coal slurry tank 6 is connected to the coal slurry feed pump 7, the coal slurry feed pump 7 is connected to the gasifier 9 through the coal slurry delivery pipe 8, and the coal slurry delivery pipe 8 A heating device 10 is provided on it, and a temperature detection device 11 is also provided on the coal slurry delivery pipe 8 .

Embodiment 2

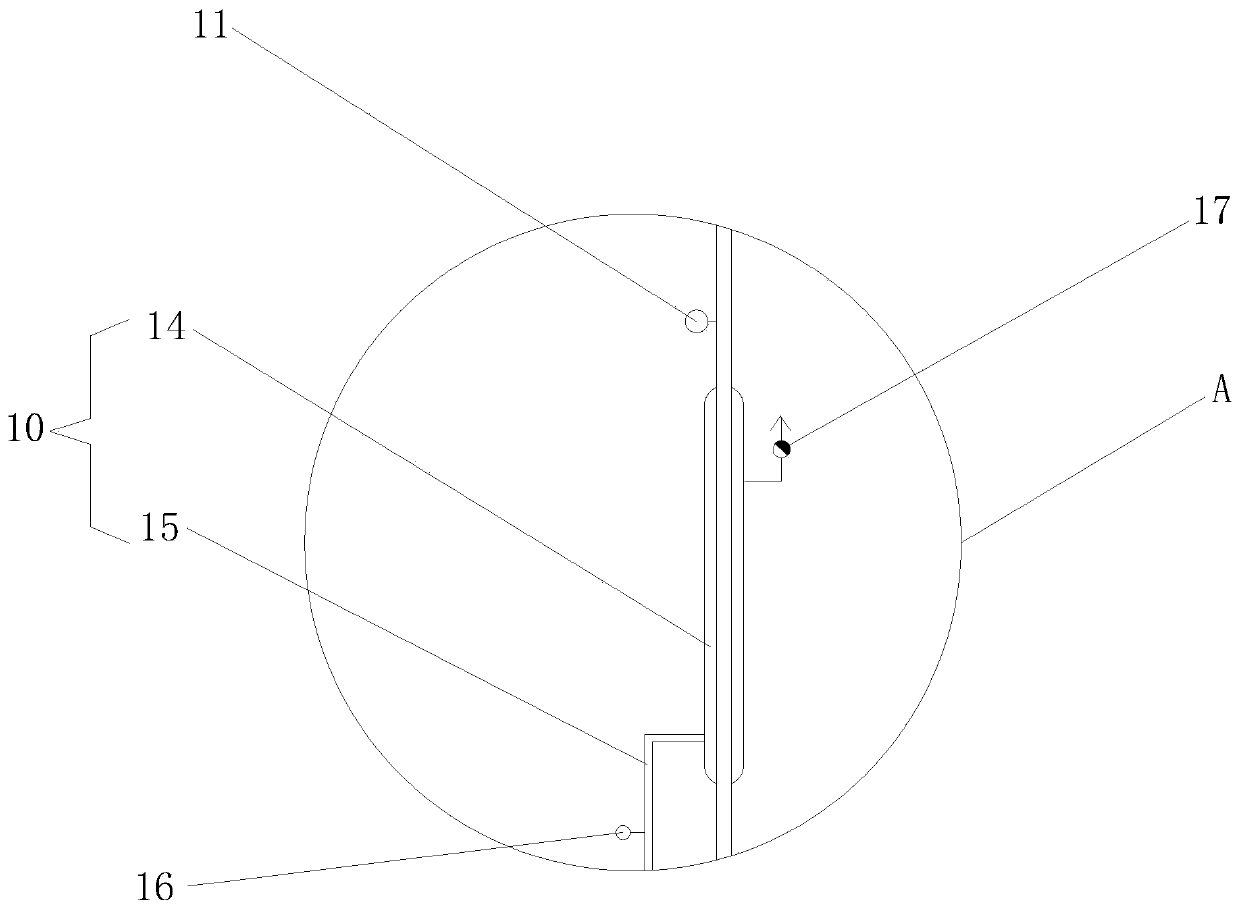

[0022] Embodiment 2 of the present invention: a low-energy-consumption coal-water slurry gasification system, comprising a coal storage hopper 1, the discharge port of the coal storage hopper 1 is connected to a coal weighing feeder 2, and the coal weighing feeder 2 is connected to The inlet of the coal mill 3 is connected, the coal mill 3 is connected to the mill discharge chute 4, the outlet of the mill discharge chute 4 is connected to the mill discharge chute pump 5, and the mill discharge chute pump 5 Connected to the coal slurry tank 6, the coal slurry tank 6 is connected to the coal slurry feed pump 7, the coal slurry feed pump 7 is connected to the gasifier 9 through the coal slurry delivery pipe 8, and the coal slurry delivery pipe 8 A heating device 10 is provided on it, and a temperature detection device 11 is also provided on the coal slurry delivery pipe 8 . The heating device 10 includes a jacketed heat tracing pipe 14 and a steam conveying pipe 15 . The jacketed...

Embodiment 3

[0023] Embodiment 3 of the present invention: a low-energy-consumption coal-water slurry gasification system, comprising a coal storage hopper 1, the discharge port of the coal storage hopper 1 is connected to a coal weighing feeder 2, and the coal weighing feeder 2 is connected to The inlet of the coal mill 3 is connected, the coal mill 3 is connected to the mill discharge chute 4, the outlet of the mill discharge chute 4 is connected to the mill discharge chute pump 5, and the mill discharge chute pump 5 Connected to the coal slurry tank 6, the coal slurry tank 6 is connected to the coal slurry feed pump 7, the coal slurry feed pump 7 is connected to the gasifier 9 through the coal slurry delivery pipe 8, and the coal slurry delivery pipe 8 A heating device 10 is provided on it, and a temperature detection device 11 is also provided on the coal slurry delivery pipe 8 . The heating device 10 includes a jacketed heat tracing pipe 14 and a steam conveying pipe 15 . The jacketed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com