A dark-color polyester fabric post-treatment process

A polyester fabric and post-processing technology, applied in the textile field, can solve problems such as complicated procedures, increased difficulty in sewage treatment, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

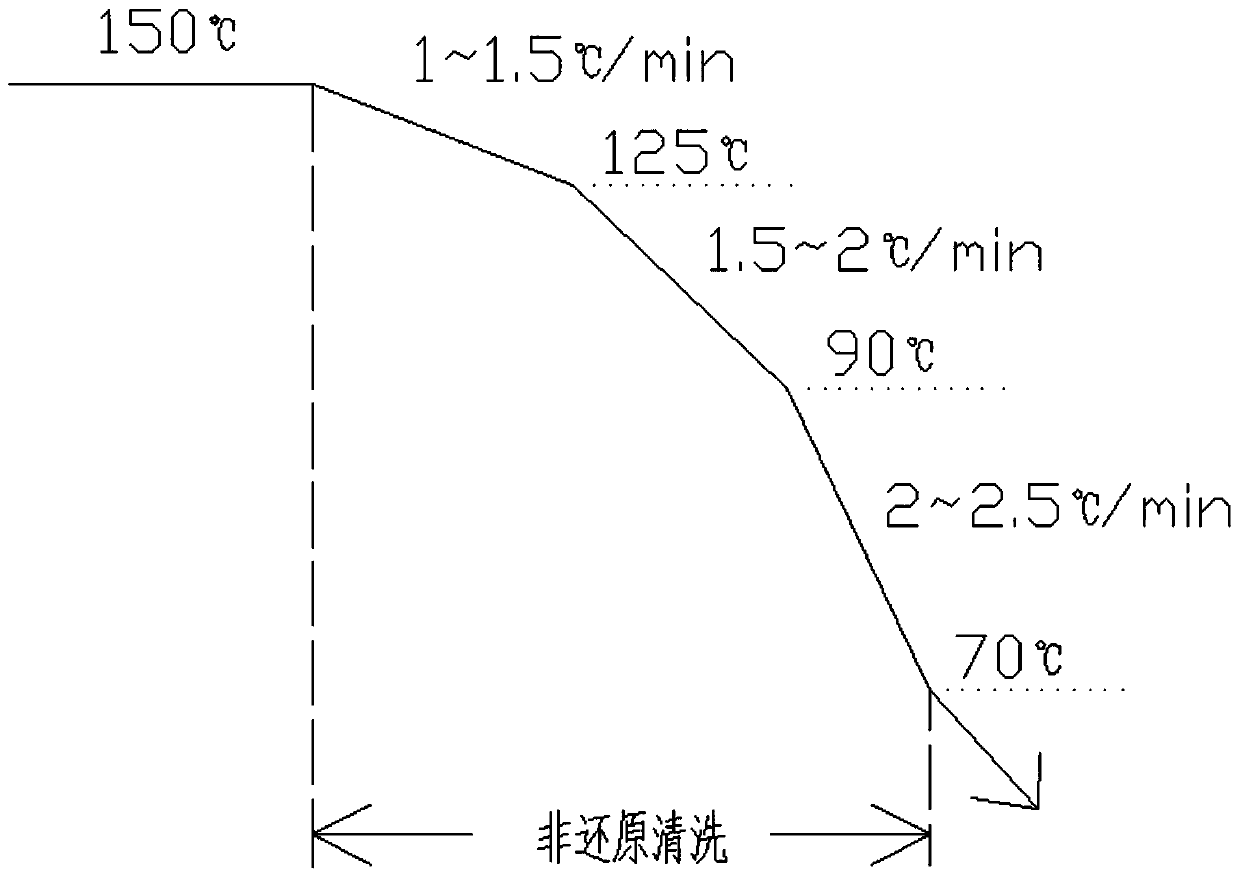

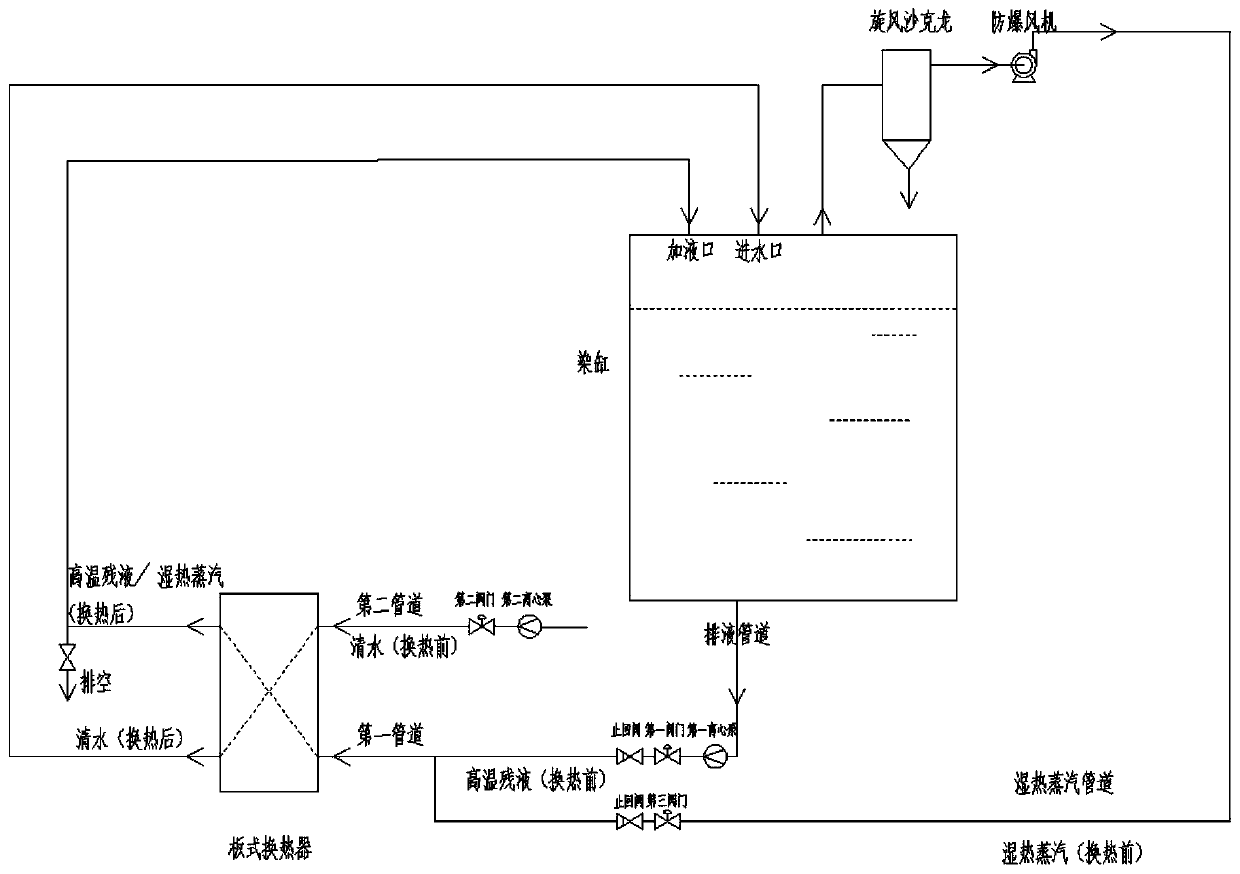

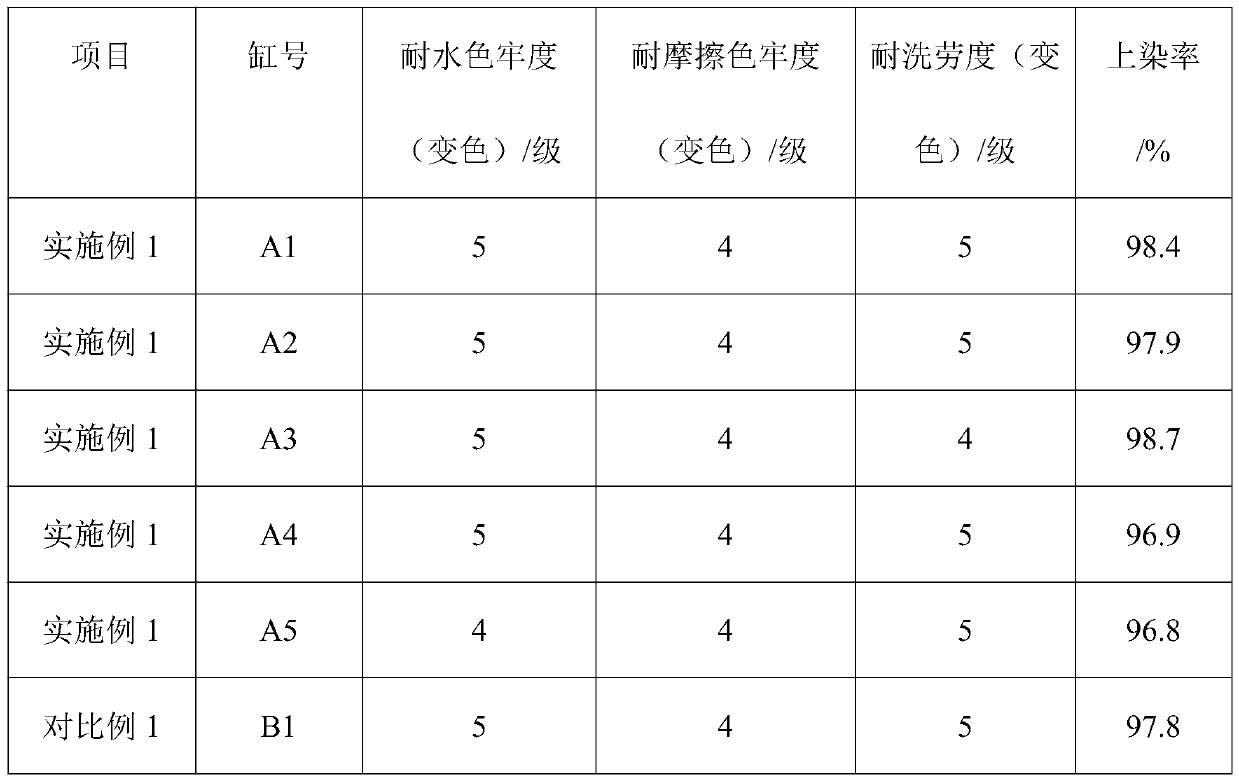

[0023] After degreasing and pre-setting, the polyester fabric falls into the dyeing vat. The pressure in the dyeing vat is 4bar. Add water to soak the polyester fabric and raise the temperature to 40°C. After diluting and mixing the disperse dyes in the auxiliary vat, add the disperse dyes into the dyeing vat. Control the bath ratio to 1:12, so that the temperature of the dyeing liquor is raised to 80°C for the first time at a rate of 2°C / min, then add acetic acid and sodium acetate buffer regulator to adjust the pH of the dyeing liquor to 4.5-4.8, and then increase the temperature at a rate of 1°C / min The rate is raised to 150°C for the second time for dyeing and heat preservation; at the same time, the dyeing tank drain inlet pipe and the hot and humid steam pipe in the first pipe of the plate heat exchanger are opened, and the plate heat exchanger is used for heat exchange, heating and cleaning. The residual liquid in the dyeing vat is cooled from 150°C to 125°C for the firs...

Embodiment 2

[0042] After degreasing and presetting, the polyester fabric falls into the dyeing vat. The pressure in the dyeing vat is 6bar. Add water to soak the polyester fabric and raise the temperature to 40°C. After diluting and mixing the disperse dyes in the auxiliary vat, add the disperse dyes into the dyeing vat. Control the bath ratio to 1:12, so that the temperature of the dyeing liquor is raised to 80°C for the first time at a rate of 2°C / min, then add acetic acid and sodium acetate buffer regulator to adjust the pH of the dyeing liquor to 4.5-4.8, and then increase the temperature at a rate of 1°C / min The rate is raised to 150°C for the second time for dyeing and heat preservation; at the same time, the dyeing tank drain inlet pipe and the hot and humid steam pipe in the first pipe of the plate heat exchanger are opened, and the plate heat exchanger is used for heat exchange, heating and cleaning. Let the residual liquid in the dyeing vat cool down from 150°C to 125°C for the f...

Embodiment 3

[0044] After degreasing and pre-setting, the polyester fabric falls into the dyeing vat. The pressure in the dyeing vat is 5bar. Add water to soak the polyester fabric and raise the temperature to 40°C. After diluting and mixing the disperse dyes in the auxiliary vat, add the disperse dyes into the dyeing vat. Control the bath ratio to 1:12, so that the temperature of the dyeing liquor is raised to 80°C for the first time at a rate of 2°C / min, then add acetic acid and sodium acetate buffer regulator to adjust the pH of the dyeing liquor to 4.5-4.8, and then increase the temperature at a rate of 1°C / min The rate is raised to 150°C for the second time for dyeing and heat preservation; at the same time, the dyeing tank drain inlet pipe and the hot and humid steam pipe in the first pipe of the plate heat exchanger are opened, and the plate heat exchanger is used for heat exchange, heating and cleaning. Make the residual liquid in the dyeing vat cool down from 150°C to 125°C for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com