LED lamp

A technology of LED lamps and LED light sources, which is applied to lampshades, lighting devices, cooling/heating devices of lighting devices, etc., can solve the problems of environmental protection, troublesome recycling, etc., and achieve low cost, increased heat dissipation surface area, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

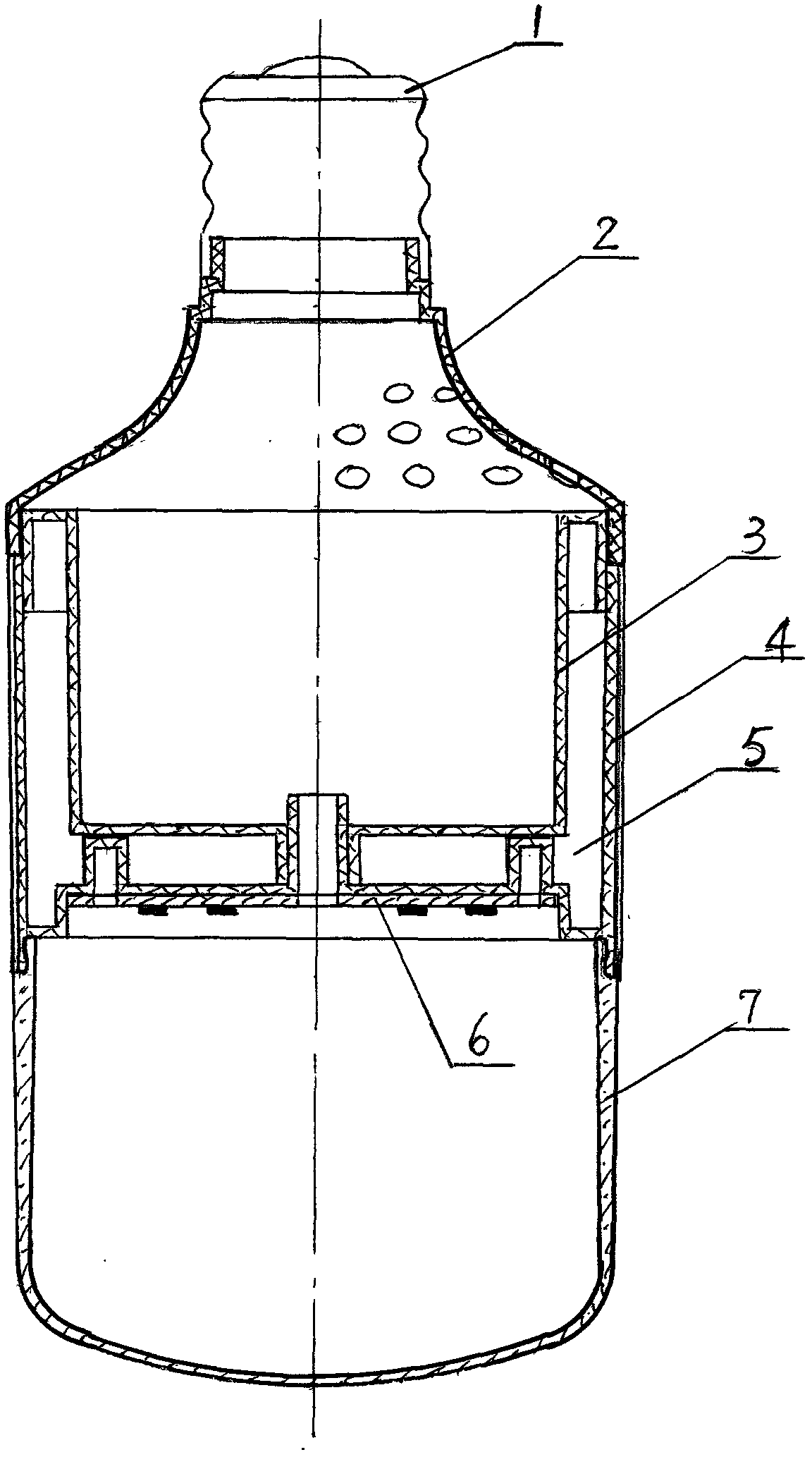

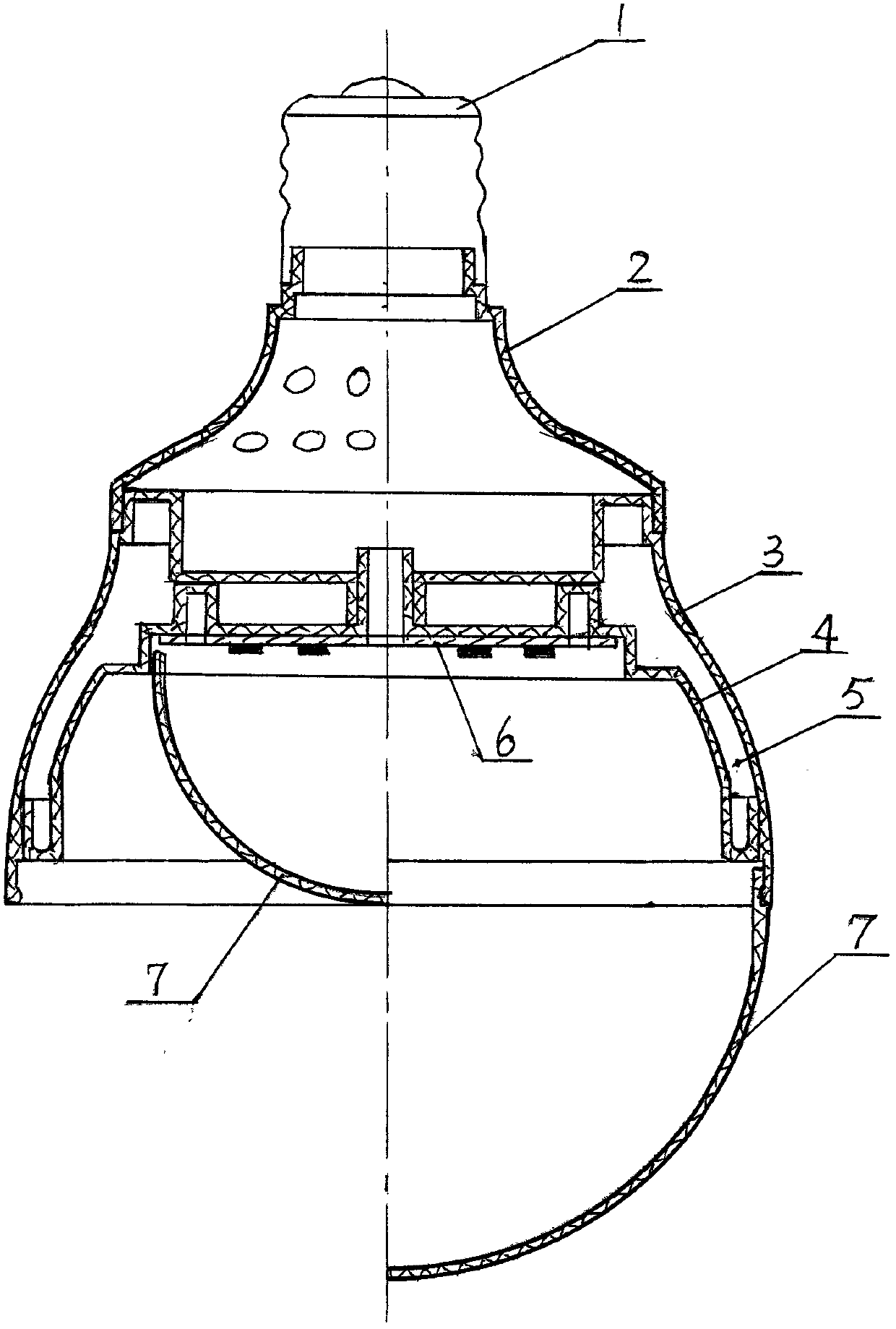

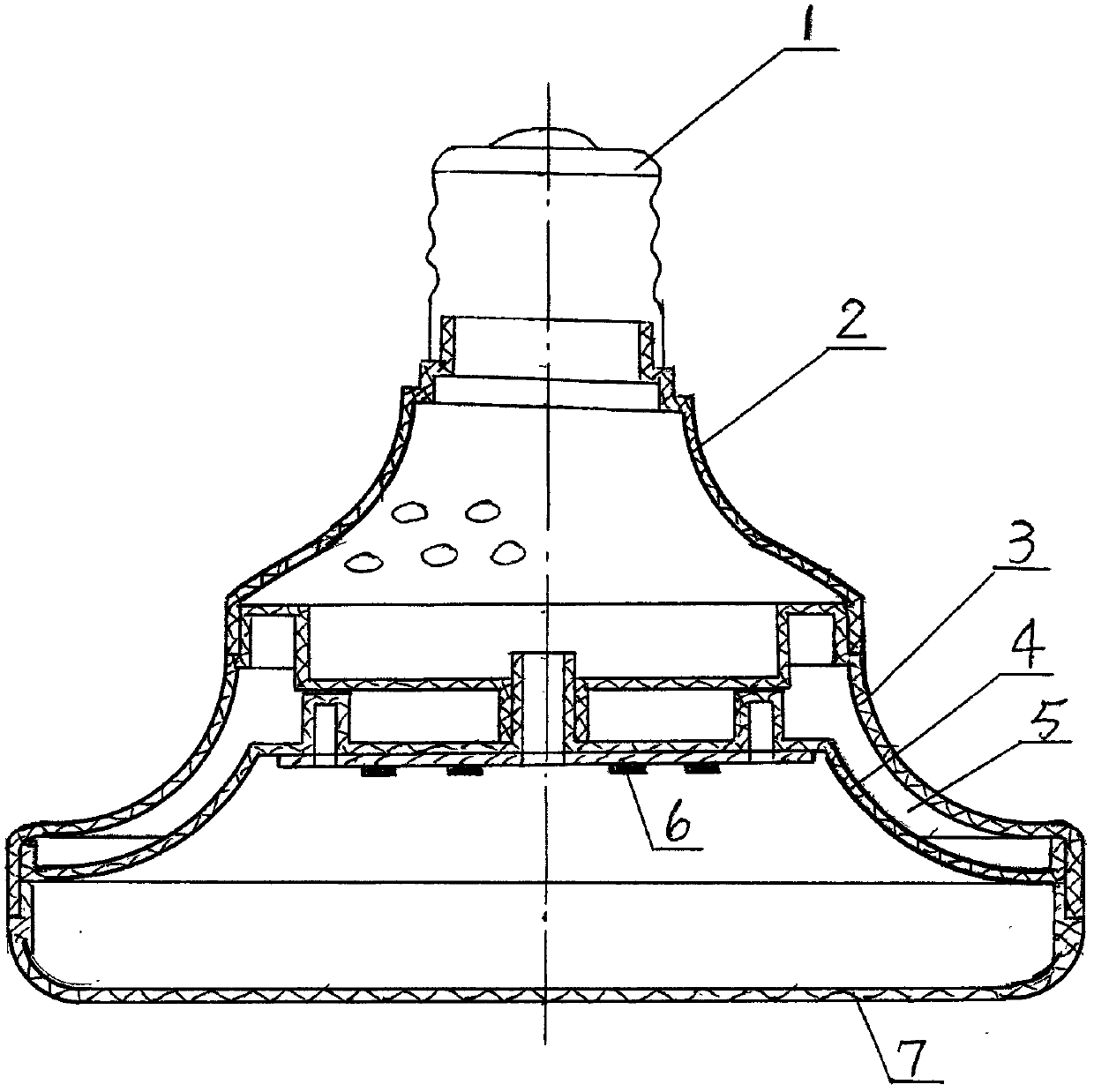

[0012] See figure 1 , figure 2 , image 3 , the lamp cap 1 is installed on the lamp cap plastic part 2, the shape of the lamp cap plastic part 2 can be changed, there may or may not be a ventilation hole on it, the heat dissipation lamp body is formed by sealing the plastic part 3 and the plastic part 4, and the space between the two plastic parts A closed cavity 5 is formed, in which a heat-conducting liquid is injected. figure 1 The middle plastic part 3 and the plastic part 4 are designed in the shape of a cylinder. The two plastic parts are sealed and connected at the upper port, and there is an outlet hole in the center of the lower end to communicate with each other. The LED light source circuit board assembly 6 is installed on the bottom of the lamp body plastic part 4. On a plane, the lampshade 7 covers it, and the lampshade 7 is shown in the shape of a column bubble, but it can be in any shape. The heat energy generated by the LED light source is conducted to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com