A method for checking the fatigue strength of a flange connecting bolt

A technology for fatigue strength and connection bolts, which is applied in the field of checking the fatigue strength of flange connection bolts, can solve problems such as increasing calculation errors, and achieve the effect of accurate relationship, simple process and high precision of calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] In this embodiment, Hypermesh is used for finite element preprocessing operation, Abaqus is used for unit load solution, and Bladed software is used for rainflow counting and damage accumulation calculation.

[0025] A method for checking the fatigue strength of flange connection bolts, comprising the following steps:

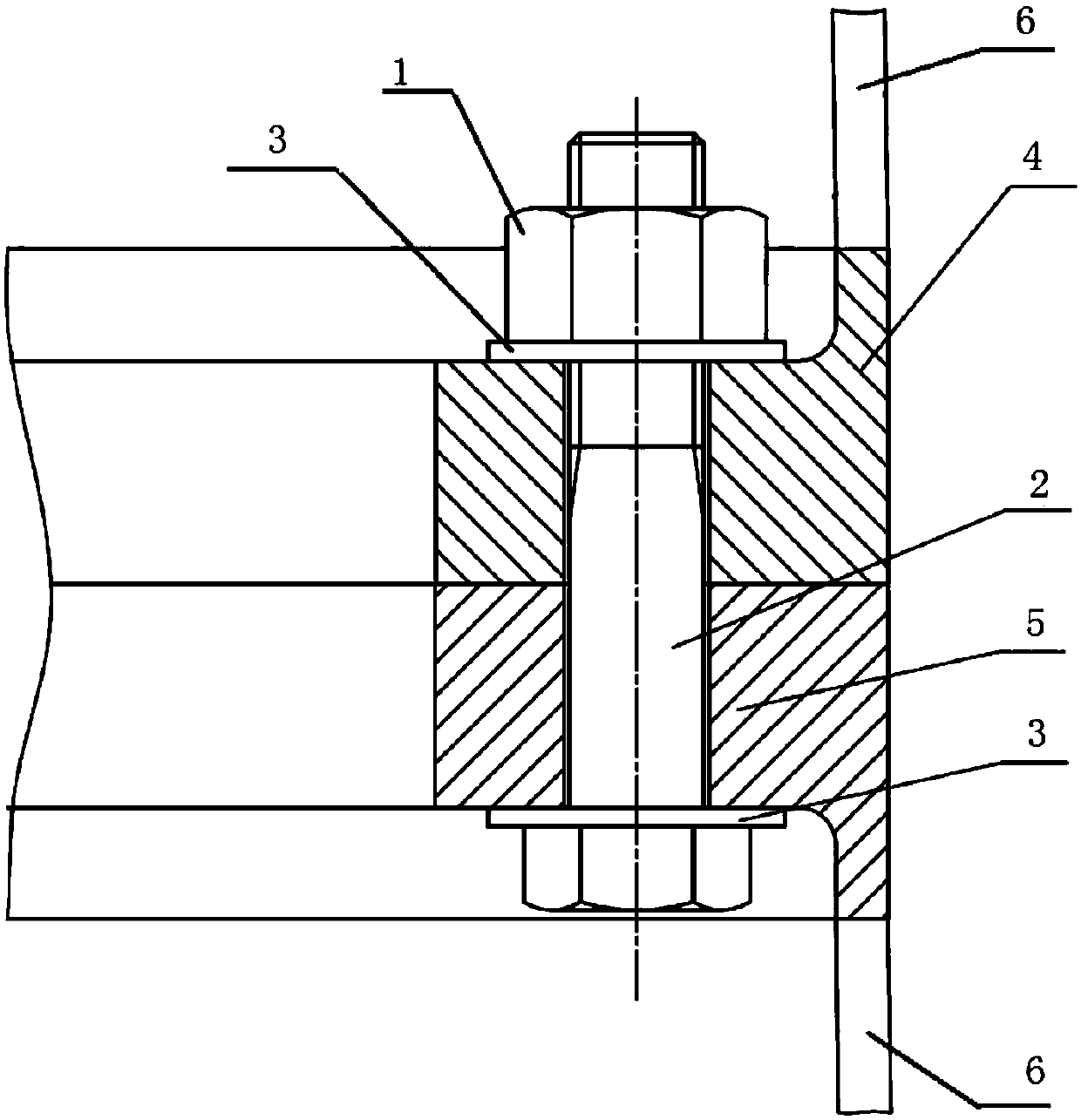

[0026] Step 1: Process the assembly of the flange connection structure in Hypermesh software to establish finite element modeling, in which the length of the tower prosthesis connected to the flange is not less than twice the outer diameter of the flange, the upper flange and The frictional contact relationship between the lower flange is set, the frictional contact relationship is set between the high-strength washer and the upper flange and between the high-strength washer and the lower flange, and the relationship between the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com