Transparent conductive film having piezoelectric effect and preparation method thereof

A transparent conductive film, piezoelectric effect technology, applied in cable/conductor manufacturing, conductive layer on insulating carrier, piezoelectric device/electrostrictive device, etc. Folding and other problems to achieve the effect of increasing the application range, reducing the electrical resistance value, and increasing the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

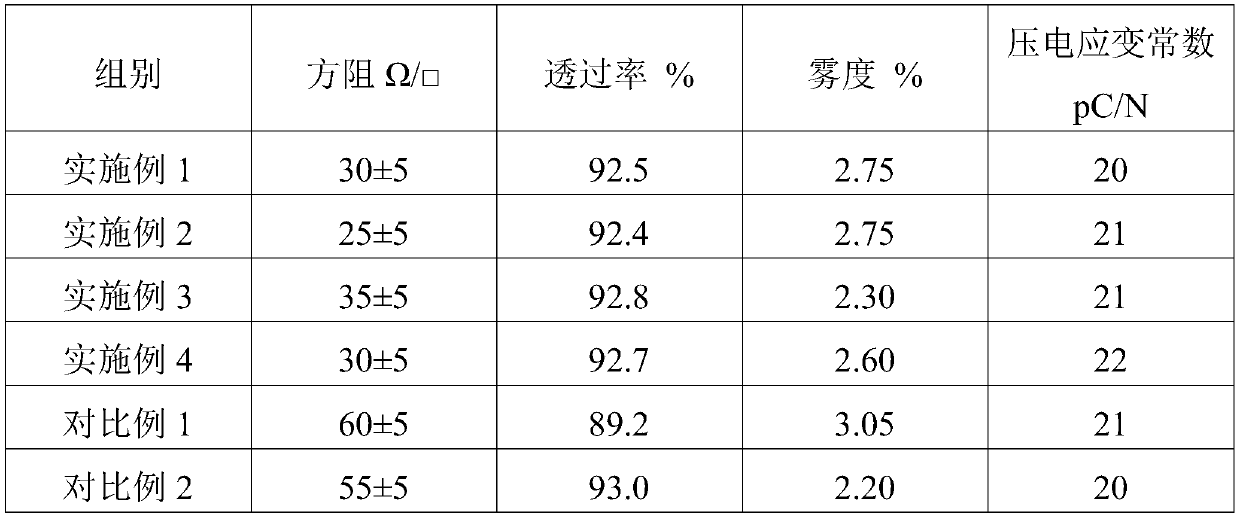

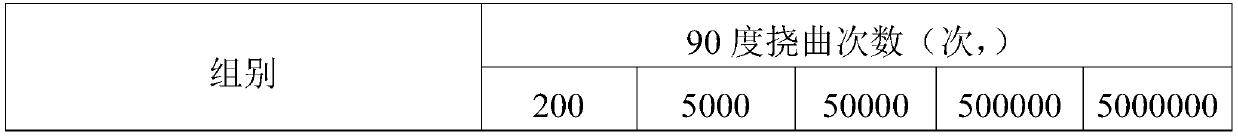

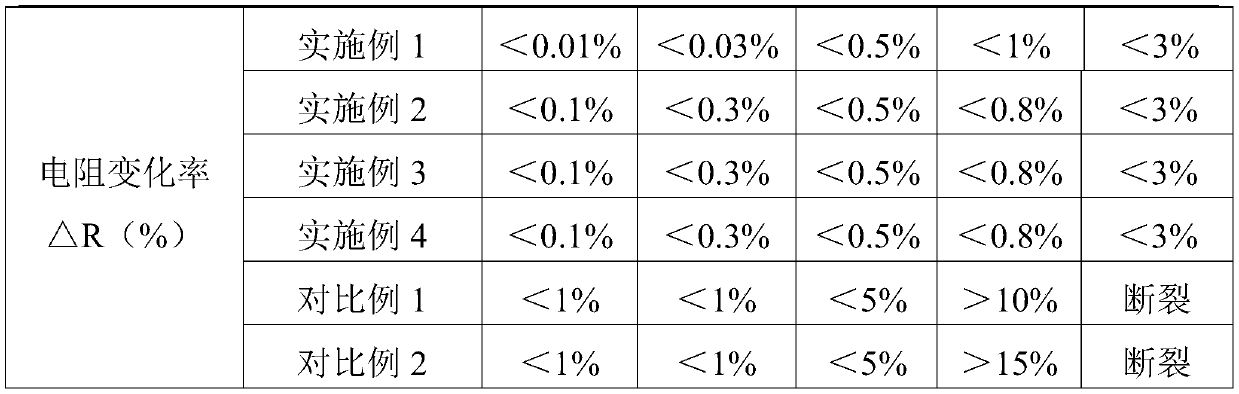

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of a transparent conductive film with piezoelectric effect, comprising the following steps:

[0033] (1) Silver nanowire 0.1-0.5wt%, adhesive 0.5-1.0wt%, leveling agent 0.1-0.5wt%, surfactant 0.05-0.1wt%, antioxidant 0.001-0.005wt% and ultrapure Water is added into the blender for defoaming and uniform mixing to obtain the first mixture;

[0034] (2) 1-5 parts of acrylic resin, 0.5-2 parts of photoinitiator, 0.1-0.5 parts of leveling agent, SiO 2 Stirring and mixing 0.01-0.05 parts of nanoparticles and 80-90 parts of organic solvents to obtain a second mixture;

[0035] (3) coat the first mixture on the base film, and bake and solidify to obtain the nano-silver conductive layer;

[0036] In some embodiments of the present invention, the coating speed is 8-12 m / min, the curing temperature is 100-150° C., and the curing time is 80-120 s. Preferably, the coating speed is 10 m / min, the curing temperature is 120° C....

Embodiment 1

[0044] A preparation method of a transparent conductive film with piezoelectric effect, comprising the following steps:

[0045] (1) Add 0.5wt% of silver nanowires, 1.0wt% of adhesive, 0.5wt% of water-based leveling agent BYK-333, 0.1wt% of polyvinylpyrrolidone, 0.005wt% of antioxidant and 97.895wt% of ultrapure water to Degassing and mixing uniformly in a mixer to obtain the first mixture;

[0046] (2) 5 parts of acrylic resin, 1.8 parts of photoinitiator, 0.3 parts of water-based leveling agent BYK-333, SiO 2 0.05 parts of nanoparticles and 90 parts of organic solvent were stirred and mixed to obtain the second mixture;

[0047] (3) Coating the first mixture on the PET base film, the coating speed is 10m / min, and baking and curing, the curing temperature is 120°C, and the curing time is 100s to obtain the nano-silver conductive layer;

[0048] (4) Coating the second mixture on the nano-silver conductive layer, the coating speed is 4m / min, and curing by baking, the curing t...

Embodiment 2

[0050] A preparation method of a transparent conductive film with piezoelectric effect, comprising the following steps:

[0051] (1) Add 0.4wt% silver nanowire, 0.8wt% adhesive, 0.4wt% aqueous leveling agent BYK-333, 0.08wt% sodium benzenesulfonate, 0.004wt% antioxidant and 98.316wt% ultrapure water Degassing and mixing uniformly in a blender to obtain the first mixture;

[0052] (2) 3 parts of acrylic resin, 0.5 parts of photoinitiator, 0.1 part of water-based leveling agent BYK-333, SiO 2 0.03 parts of nanoparticles and 85 parts of organic solvent were stirred and mixed to obtain the second mixture;

[0053] (3) Coating the first mixture on the PET base film, the coating speed is 8m / min, and baking and curing, the curing temperature is 100°C, and the curing time is 80s to obtain the nano-silver conductive layer;

[0054] (4) Coating the second mixture on the nano-silver conductive layer, the coating speed is 3m / min, and baking and curing, the curing temperature is 100°C, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com