Fresh and wet noodles with low cooking loss ratio and preparing method thereof

A loss rate and noodle technology, which is applied in the field of fresh and wet noodles and its preparation, can solve the problems of no set of process schemes, single use of food additives, poor cooking loss rate, etc., to improve gel strength and thermal processing stability properties, improving thermal processing stability, improving structure and texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

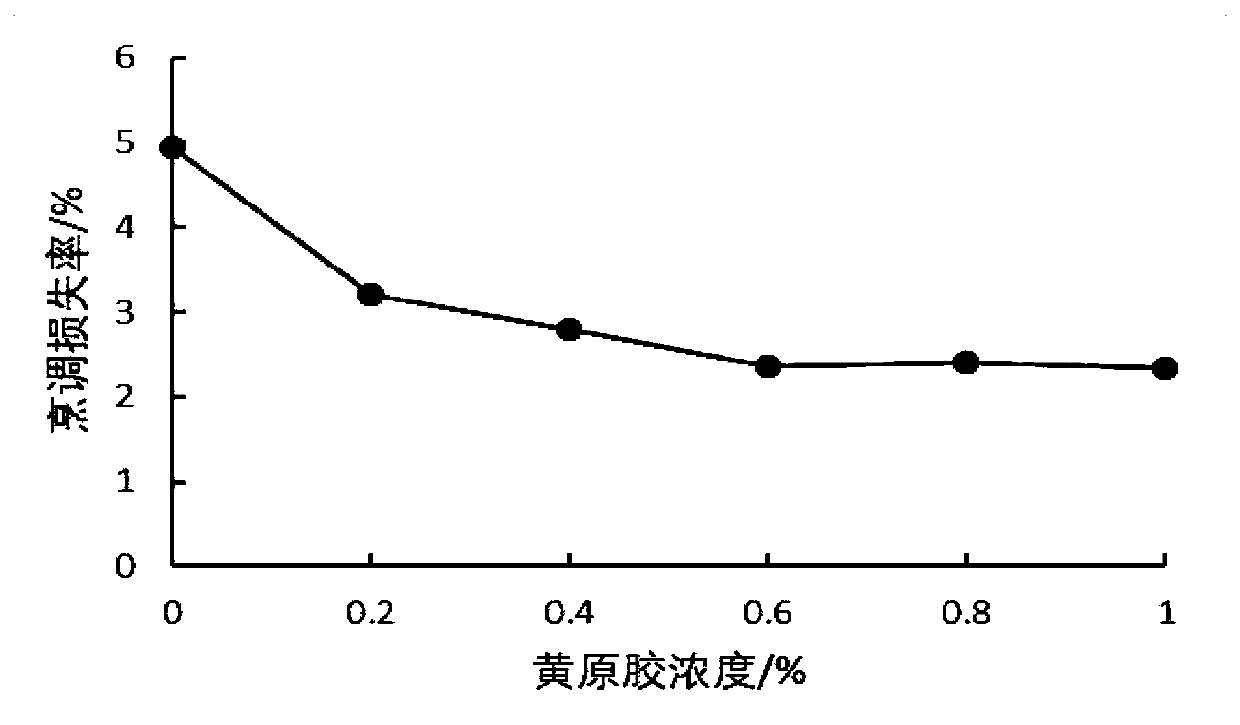

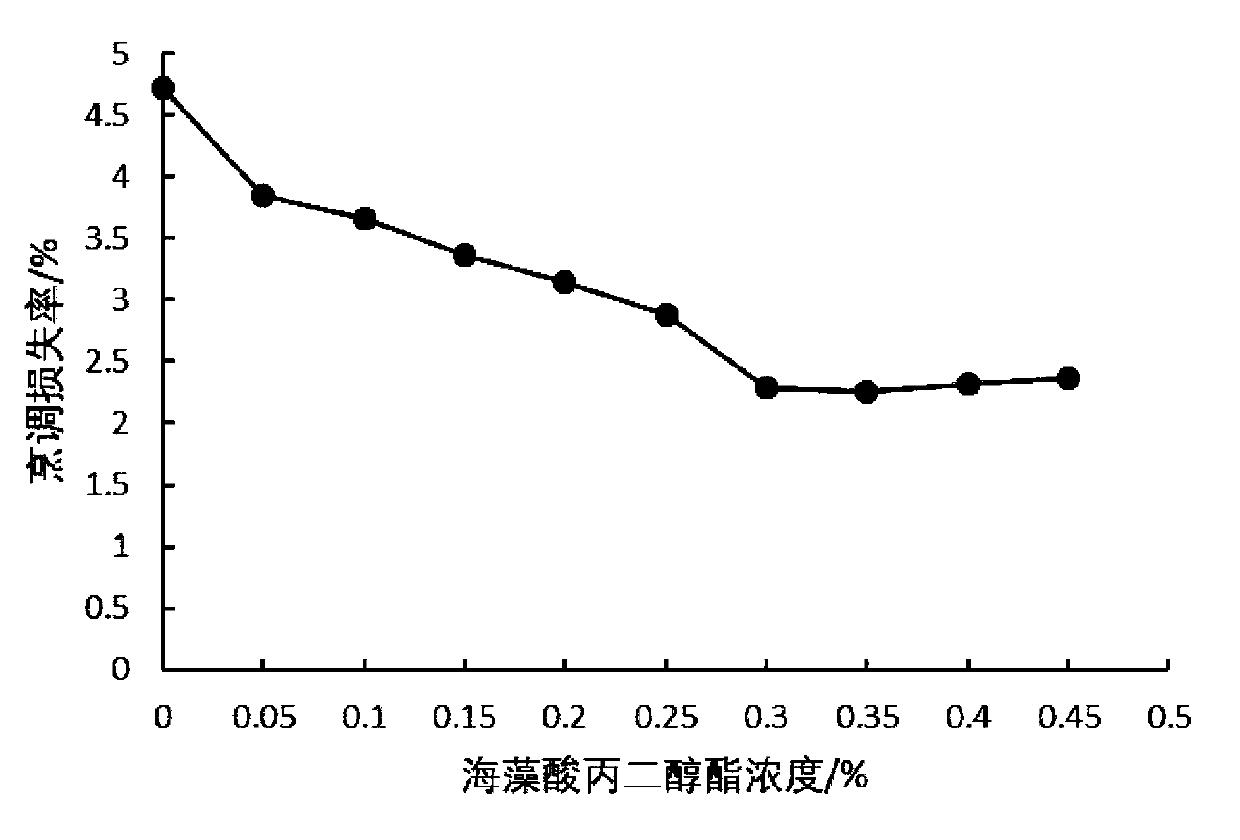

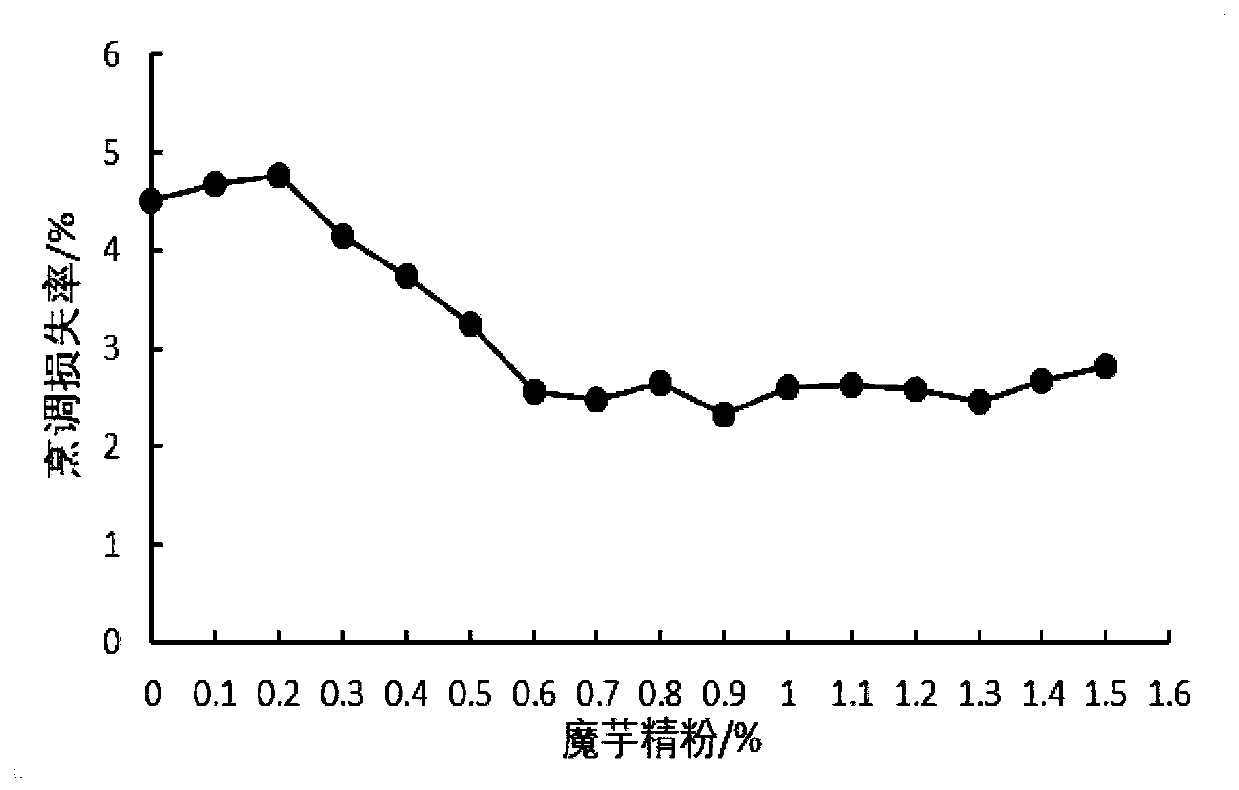

Method used

Image

Examples

Embodiment 1

[0040] 1) Take high-gluten flour as the main raw material, and mix 1.5 parts of salt into it;

[0041] 2) Add xanthan gum, propylene glycol alginate, konjac fine powder and water in step 1; The dosage is 33 parts, xanthan gum, propylene glycol alginate and konjac powder need to be dissolved in water first;

[0042] 3) Vacuum knead the raw and auxiliary materials obtained in step 2 at 25°C for 10 minutes at a stirring speed of 100 r / min, then rest the dough at 25°C for 25 minutes, and stir and mix the raw and auxiliary materials once every 5 minutes;

[0043] 4) The dough obtained in step 3 is rolled, the number of times of rolling is 8 times, and the horizontal and vertical rolling are 4 times respectively, and the final thickness of the dough is 2mm;

[0044] 5) Stack the noodle strips obtained in step 4 to 6 layers and press them tightly, then proof for 10 minutes, and then calender again, the number of times of calendering is 4 times, the final noodle strip thickness is 1....

Embodiment 2

[0048] 1) Use high-gluten flour as the main raw material, and mix 2 parts of salt into it;

[0049] 2) Add xanthan gum, propylene glycol alginate, konjac powder and water in step 1; the consumption of xanthan gum is 0.3 part, the consumption of propylene glycol alginate is 0.2 part, the consumption of konjac powder is 0.6 part, water The dosage is 33 parts, xanthan gum, propylene glycol alginate and konjac powder need to be dissolved in water first;

[0050] 3) Vacuum knead the raw and auxiliary materials obtained in step 2 at 25°C for 15 minutes at a stirring speed of 80 r / min, then rest the dough at 25°C for 25 minutes, and stir and mix the raw and auxiliary materials once every 5 minutes;

[0051] 4) rolling the dough obtained in step 3, the number of times of rolling is 10 times, and the final thickness of the dough is 2mm;

[0052]5) Stack the noodle strips obtained in step 4 to 5 layers and press them tightly, proof for 15 minutes, and then roll again, the number of tim...

Embodiment 3

[0056] 1) Using high-gluten flour as the main raw material, mix 1.2 parts of salt into it;

[0057] 2) Add xanthan gum, propylene glycol alginate, konjac powder and water in step 1; the consumption of xanthan gum is 0.4 part, the consumption of propylene glycol alginate is 0.2 part, the consumption of konjac powder is 0.8 part, water The dosage is 35 parts, xanthan gum, propylene glycol alginate and konjac powder need to be dissolved in water first;

[0058] 3) Vacuum knead the raw and auxiliary materials obtained in step 2 at 25°C for 15 minutes at a stirring speed of 80 r / min, then rest the dough at 25°C for 25 minutes, and stir and mix the raw and auxiliary materials once every 5 minutes;

[0059] 4) The dough obtained in step 3 is rolled, the number of times of rolling is 10 times, and the horizontal and vertical rolling is 5 times respectively, and the thickness of the final dough strip is 2 mm;

[0060] 5) Stack the noodle strips obtained in step 4 to 8 layers and press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com