Electric tractor double-motor power junction control device

A control device and tractor technology, applied in the field of tractors, can solve the problems of increasing the control difficulty of the vehicle drive system, increasing the requirements of the drive motor, and the complex structure of the gearbox, so as to improve power and economy, overcome power shortage, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] For further describing the present invention, now in conjunction with accompanying drawing, the present invention is further described:

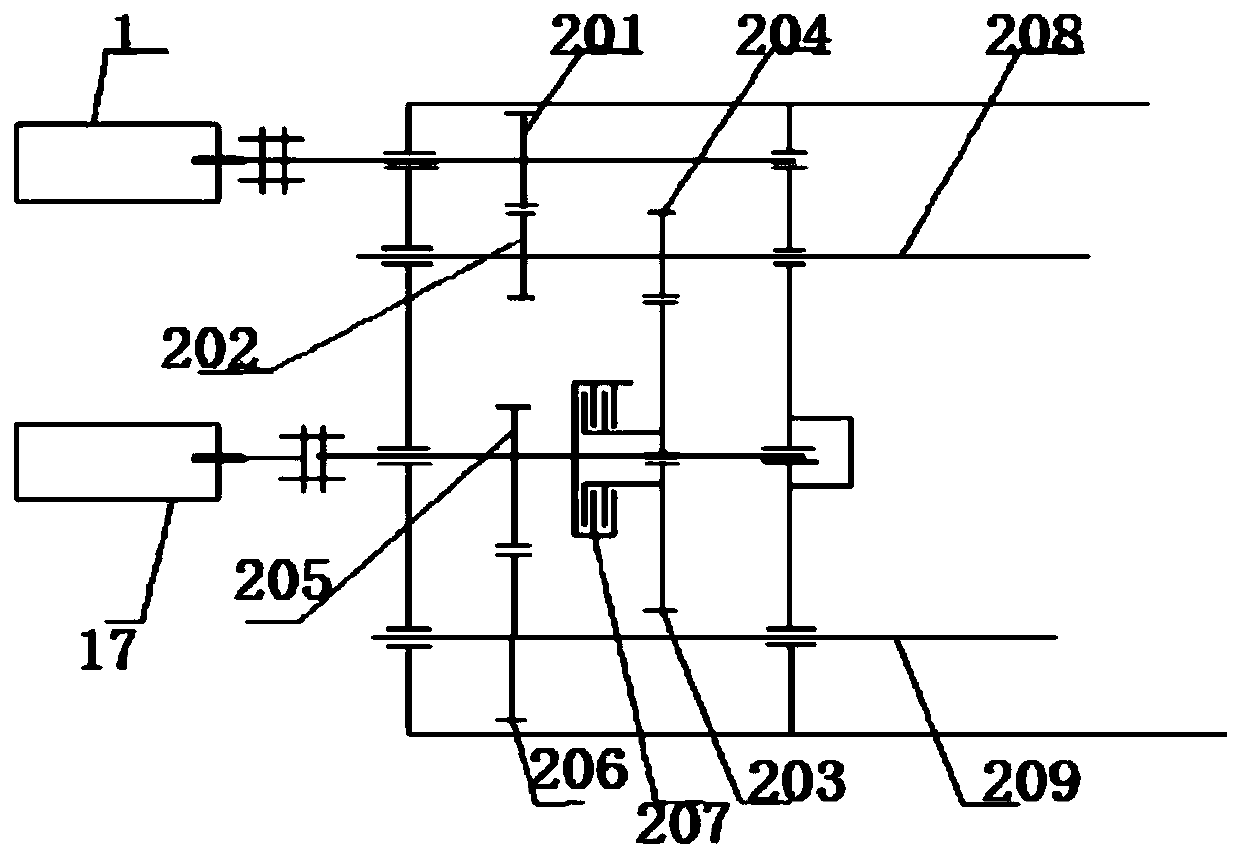

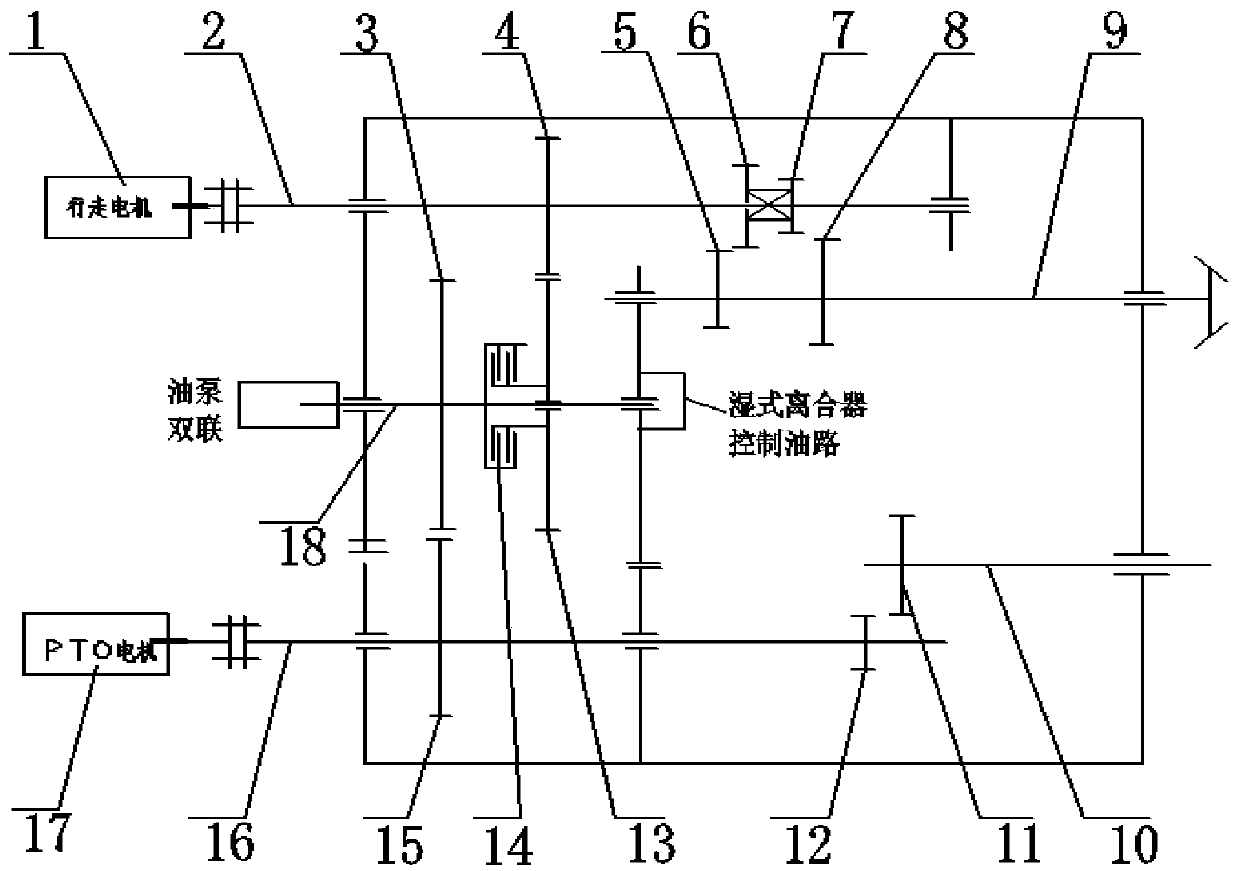

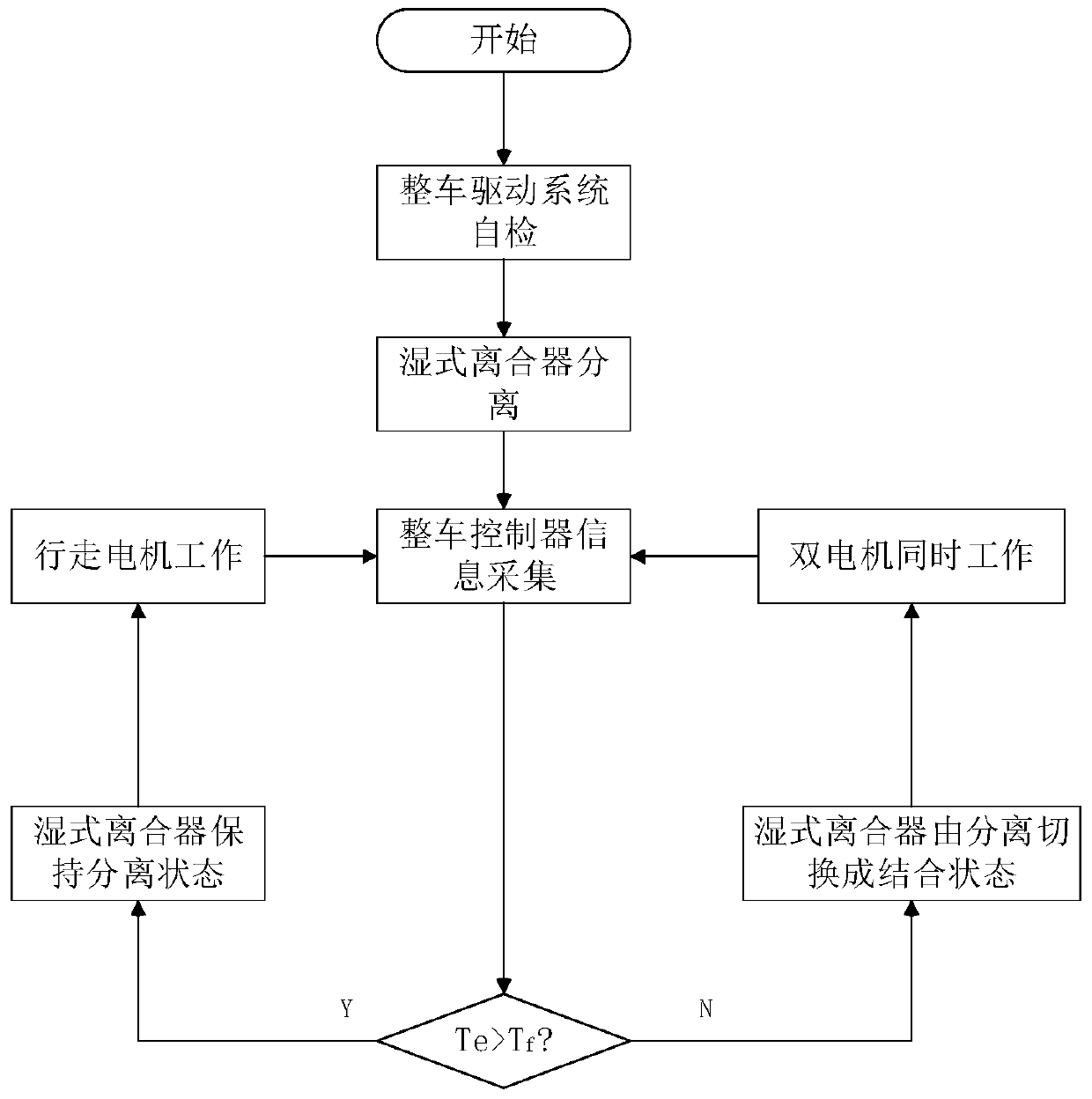

[0024] A control device for power confluence of dual motors of an electric tractor, characterized in that it includes a wet clutch control oil circuit and a power confluence gearbox; the wet clutch control oil circuit is connected in sequence according to the hydraulic oil circuit; the power confluence gearbox includes two One power input shaft, two power output shafts, a wet clutch, an intermediate shaft and several pairs of gears; the wet clutch controls the oil circuit to control the separation and combination of the wet clutch; the two power input shafts are respectively connected to the travel motor 1 and the PTO motor 17 The output shafts are connected; the two power output shafts are used to drive walking and PTO respectively. The traveling motor 1 and the PTO motor 17 are respectively controlled by a motor controller, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com