A high-content chitosan-filled 3D printing consumable and preparation method thereof

A 3D printing and chitosan technology, which is applied in the field of high-content chitosan-filled 3D printing consumables and its preparation, can solve the problems of cumbersome steps, difficulty in large-scale application, and low chitosan content, so as to alleviate oxidative degradation, The effect of protecting integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

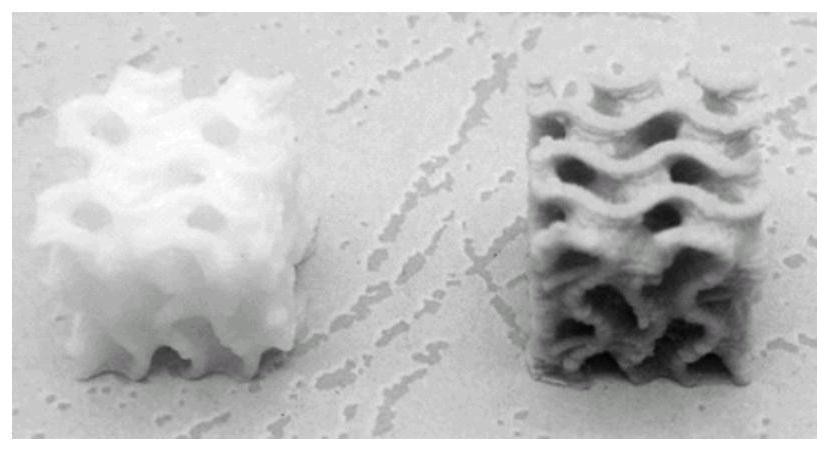

Image

Examples

Embodiment 1

[0053] 1. A high-content chitosan-filled 3D printing consumable, characterized in that:

[0054] (1) Formula according to weight percentage:

[0055] PLA50

[0056] TPU 14

[0057] Chitosan 35

[0059] Antioxidant 168 0.2

[0060] White oil 0.5

[0061] (2) Preparation method:

[0062] A. Vacuum dry PLA, TPU and chitosan for 12 h.

[0063] B. according to weight percentage formula, take by weighing PLA after drying, TPU, chitosan, then take by weighing lanthanum stearate, antioxidant 168, white oil;

[0064]C. Place the weighed components in a high-speed kneader, keep the speed at 2000 rpm, and stir at high speed for 20 min;

[0065] D. Add the above-mentioned fully mixed and uniform raw materials to the feeding port of the twin-screw extruder. The parameters of the twin-screw extruder are: the temperature of the first zone is 100 ℃, the temperature of the second zone is 115 ℃, the temperature of the third zone is 130 ℃, and the temperat...

Embodiment 2

[0070] 1. A 3D printing consumable filled with high chitosan, characterized in that:

[0071] (1) Formula according to weight percentage:

[0072] PLA 47

[0073] PBAT 11

[0074] Chitosan 41

[0075] Isooctyl tin dimethyl dimercaptoacetate 0.2

[0076] Antioxidant 1010 0.3

[0077] White oil 0.5

[0078] (2) Preparation method:

[0079] A. Vacuum dry PLA, PBAT, and chitosan for 12 h.

[0080] B. according to weight percentage formula, take by weighing PLA after drying, PBAT, chitosan, then successively take by weighing isooctyl tin dimethyl dimercaptoacetate, antioxidant 1010, white oil;

[0081] C. Place the weighed components in a high-speed kneader, keep the speed at 2500 rpm, and stir at high speed for 10 min;

[0082] D. Add the above-mentioned fully mixed and uniform raw materials to the feeding port of the twin-screw extruder. The parameters of the twin-screw extruder are: the temperature of the first zone is 110 ℃, the temperature of the second zone is 120 ℃, ...

Embodiment 3

[0087] 1. A 3D printing consumable filled with high chitosan, characterized in that:

[0088] (1) Formula according to weight percentage:

[0089] PLA 43

[0090] PBAT 11

[0091] Chitosan 45

[0093] Antioxidant 1067 0.3

[0094] White oil 0.4

[0095] (2) Preparation method:

[0096] A. Vacuum dry PLA, PBAT, and chitosan for 12 h.

[0097] B. according to weight percentage formula, take by weighing dried PLA, PBAT, chitosan, then take by weighing lanthanum stearate, antioxidant 1067, white oil;

[0098] C. Place the weighed components in a high-speed kneader, keep the speed at 1000 rpm, and stir at high speed for 40 min;

[0099] D. Add the above-mentioned well-mixed and uniform raw materials to the feeding port of the twin-screw extruder. The parameters of the twin-screw extruder are: the temperature of the first zone is 103 °C, the temperature of the second zone is 117 °C, the temperature of the third zone is 132 °C, and the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com