An installation process of a steel sleeve box used in the construction of bridge pier caps

An installation process and a technology of steel sleeve boxes, which are applied in bridges, bridge construction, infrastructure engineering and other directions, can solve the problems of difficult construction, complex construction process and high construction cost, and achieve low construction cost, reasonable layout and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

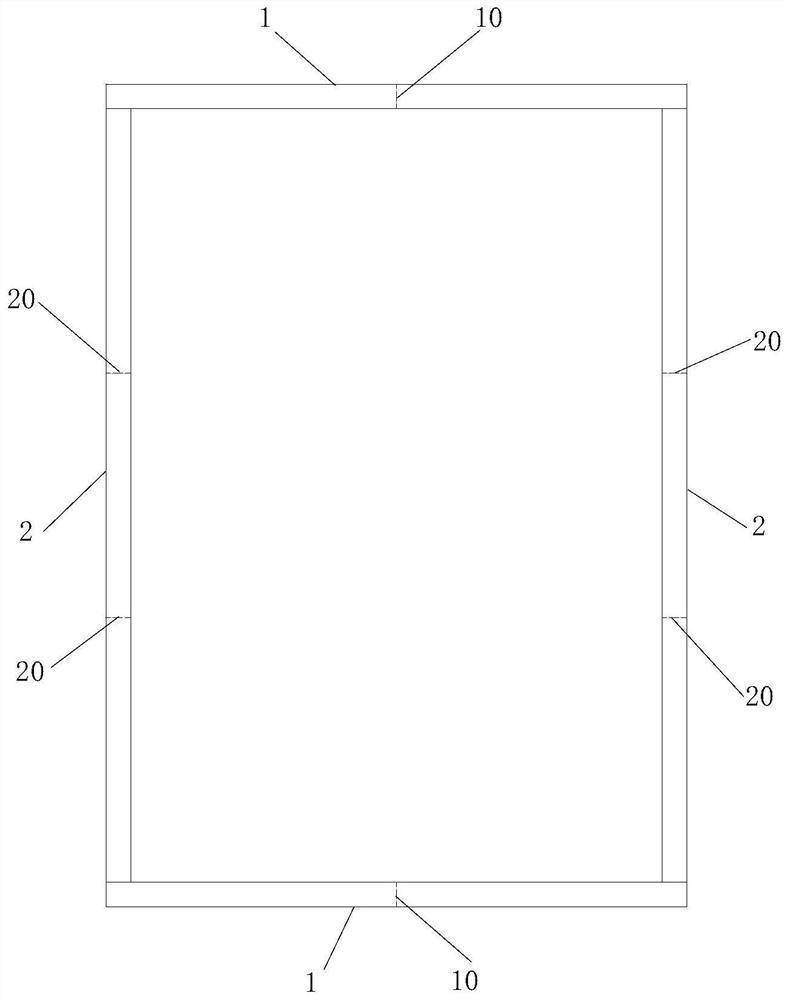

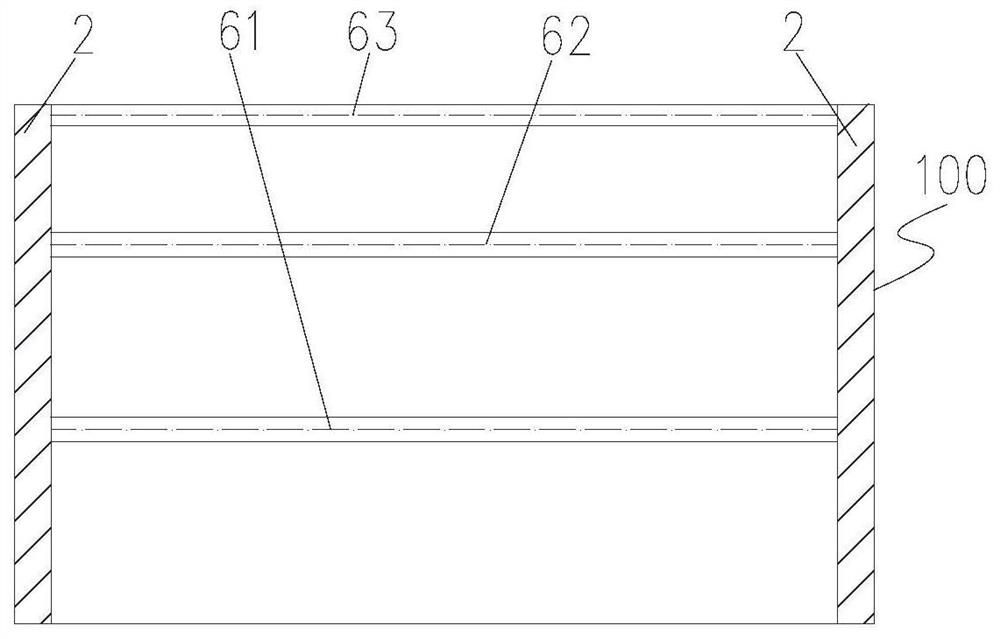

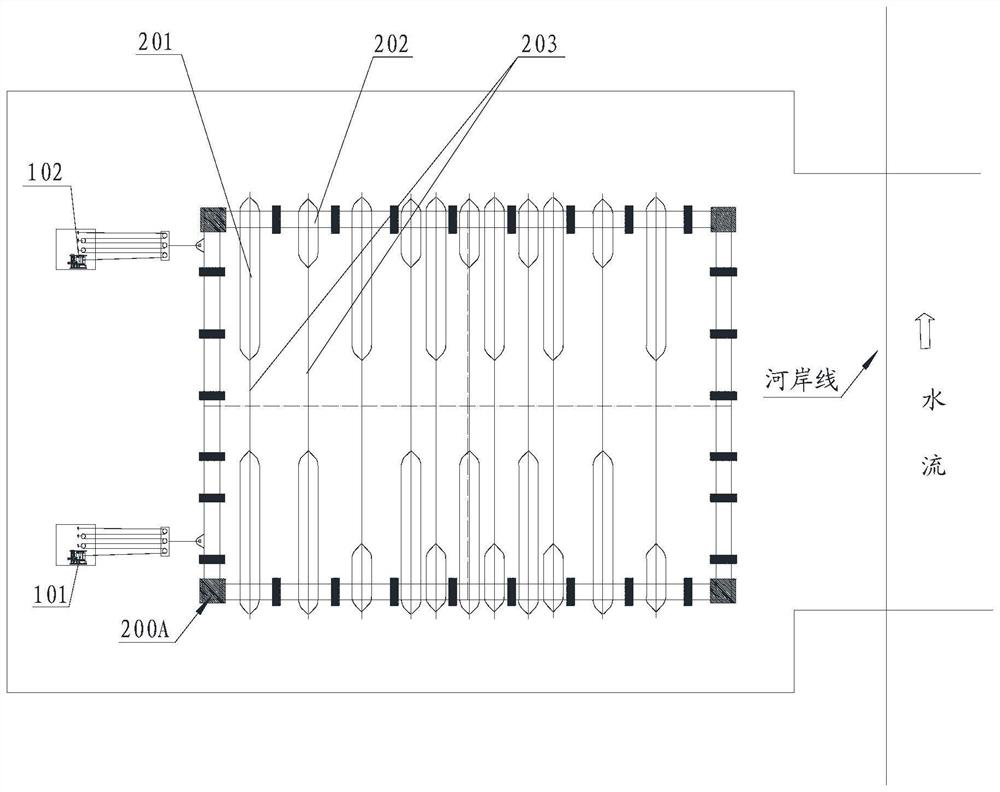

[0040] see Figure 1a and Figure 1b The steel box used in the installation process of the steel box for the construction of the pier cap of the present invention is rectangular and has a bottomless structure. The wall of the steel box 100 includes two wall panels 1 along the bridge direction and two horizontal The bridge wall 2 and the inner support, the inner support includes the first to third plane frames 61, 62, 63; the width of the wall 1 along the bridge is smaller than the width of the wall 2 of the cross bridge; The size is 40.4m in width along the bridge x 28.4m in width across the bridge; the wall 1 along the bridge and the wall 2 towards the cross bridge are double-walled structures; the wall 1 along the bridge is divided into two by a partition 10 A horizontal water-proof warehouse; the horizontal bridge to the wall plate 2 is divided into three horizontal wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com