Large-diameter directional long drill hole extraction method for mining body gushing out of gas roof

A long-drilling, large-diameter technology, applied in the fields of mining fluids, gas discharge, mining equipment, etc., can solve the problems of affecting the release of high-yield potential, low efficiency, large engineering volume, etc., to improve the scope of application, reduce gas concentration, improve The effect of extraction success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

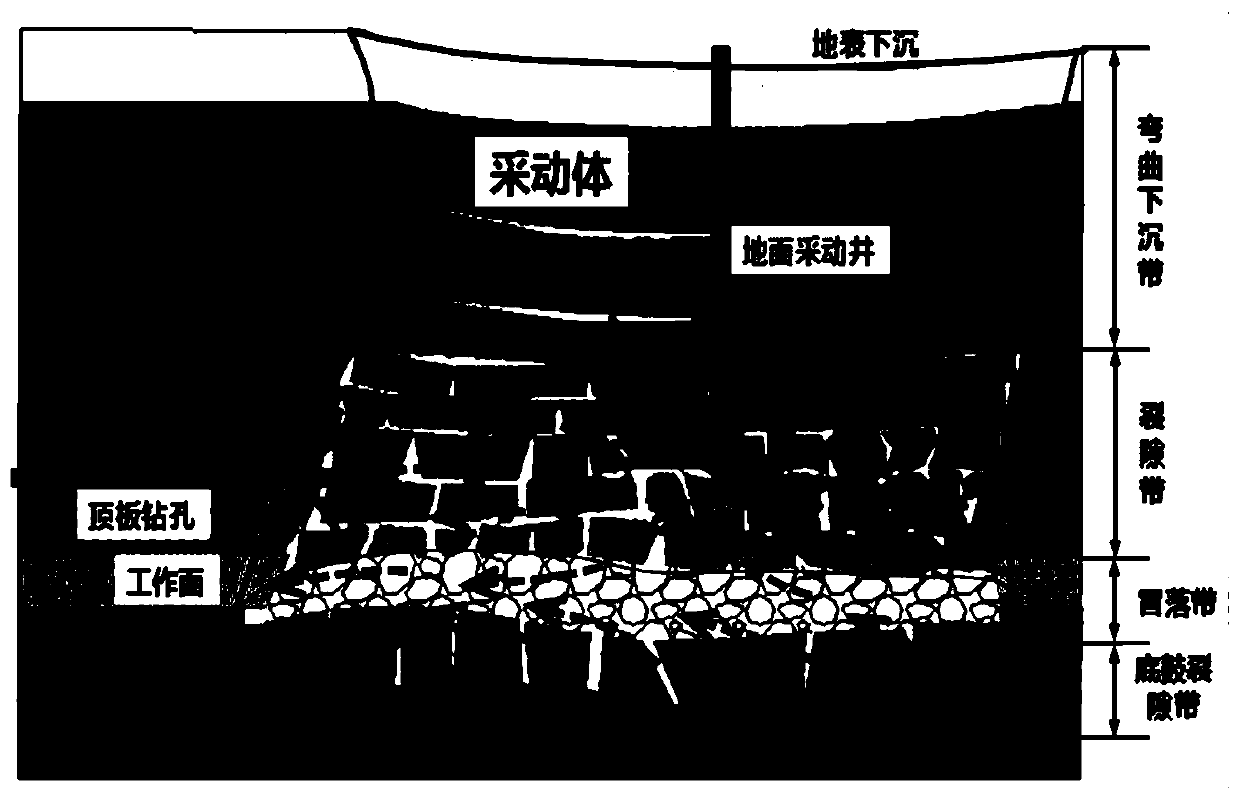

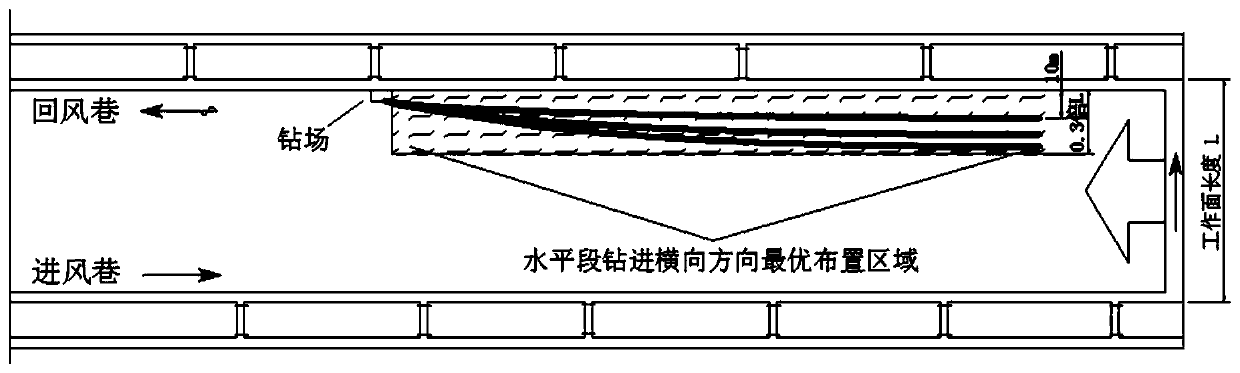

[0042] Such as figure 1 As shown, the extraction method of large-diameter directional long drilling holes on the gas roof gushing out of the mining body according to the present invention specifically includes the following steps:

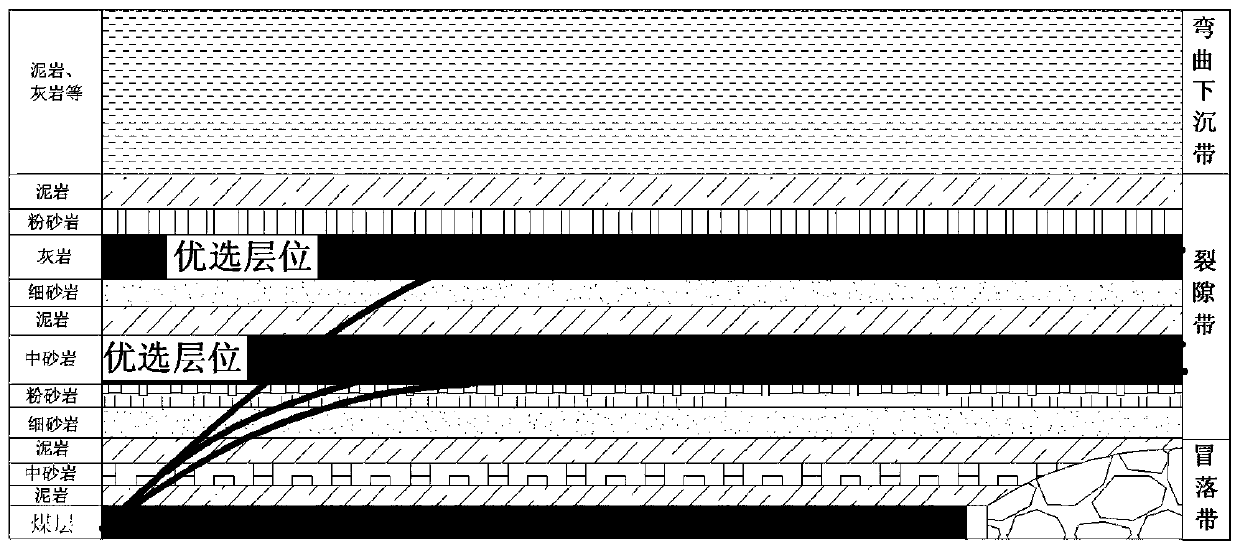

[0043] S1: Calculate and determine the basic parameters of large-diameter directional long drilling on the roof, including the longitudinal height of the hole layout area, the number of drilling holes, the selection of drilling layers in the horizontal section and the spatial layout, drilling site and drilling parameters;

[0044] (1) Determination of the vertical height of the hole layout area

[0045] In order to effectively control the gas in the upper corner, the long drilling holes for drainage should be arranged in the roof strata near the return air roadway of the working face. In order to ensure the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com