Fuel injection device, tappet and tappet housing

A shell and pin technology, applied in fuel injection devices, fuel injection pumps, charging systems, etc., can solve the problems of high cost and reduced assembly joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It can be seen from the background art that the technical problem solved by the embodiments of the present invention is to simplify the assembly between the pin and the housing and improve the assembly efficiency.

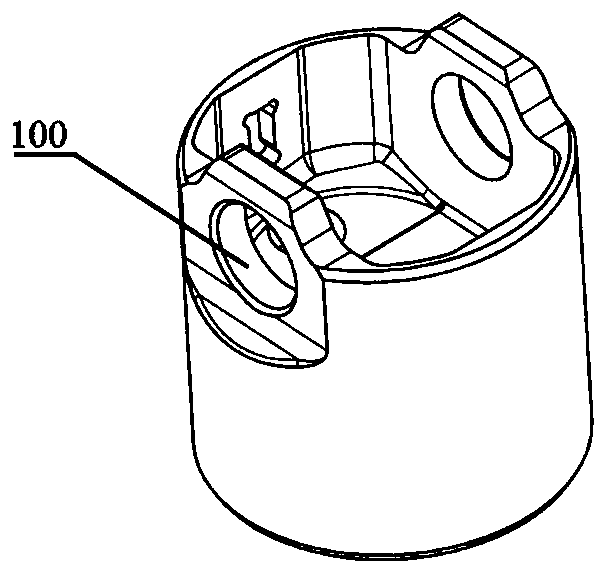

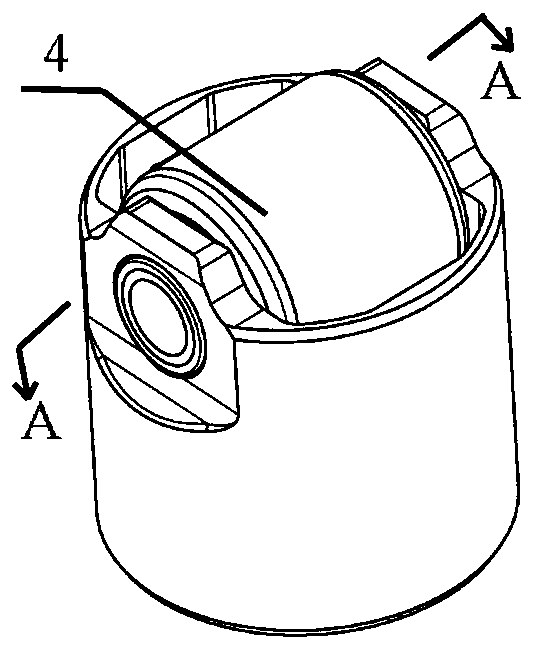

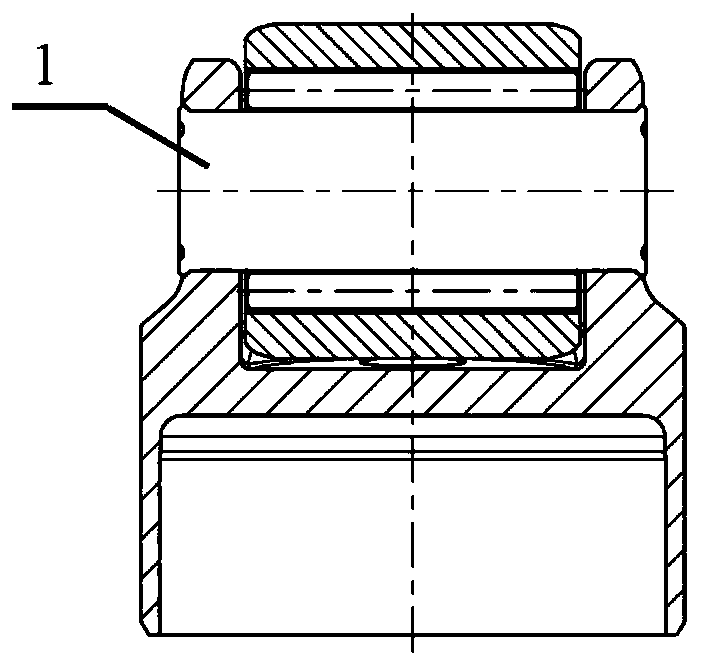

[0034] Please refer to Figure 1-Figure 3 , figure 1 is a structural schematic diagram of a tappet shell; figure 2 is a structural schematic diagram of a tappet; image 3 yes figure 2 Sectional view along A-A direction.

[0035] As shown in the figure, a tappet includes a tappet housing, a pin 1, a roller (not shown) and a roller 4, and the housing is provided with a pin hole 100. When assembling the tappet, the roller is first loaded into The inner surface of the roller 4, and insert the pin 1 substitute inside the roller, so that the rollers are distributed on the inner ring surface of the roller 4, that is, the pre-assembly of the roller and the roller 4 is completed. After that, the assembly of the roller and the roller 4 is put into the tappet ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com