A kind of voc tail gas water sealing device and water sealing method

A technology of water sealing device and exhaust gas, which is applied in the direction of valve device, valve heating/cooling device, valve details, etc., which can solve the problems of generating air bubbles, entraining liquid droplets, affecting the effect of condensate recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

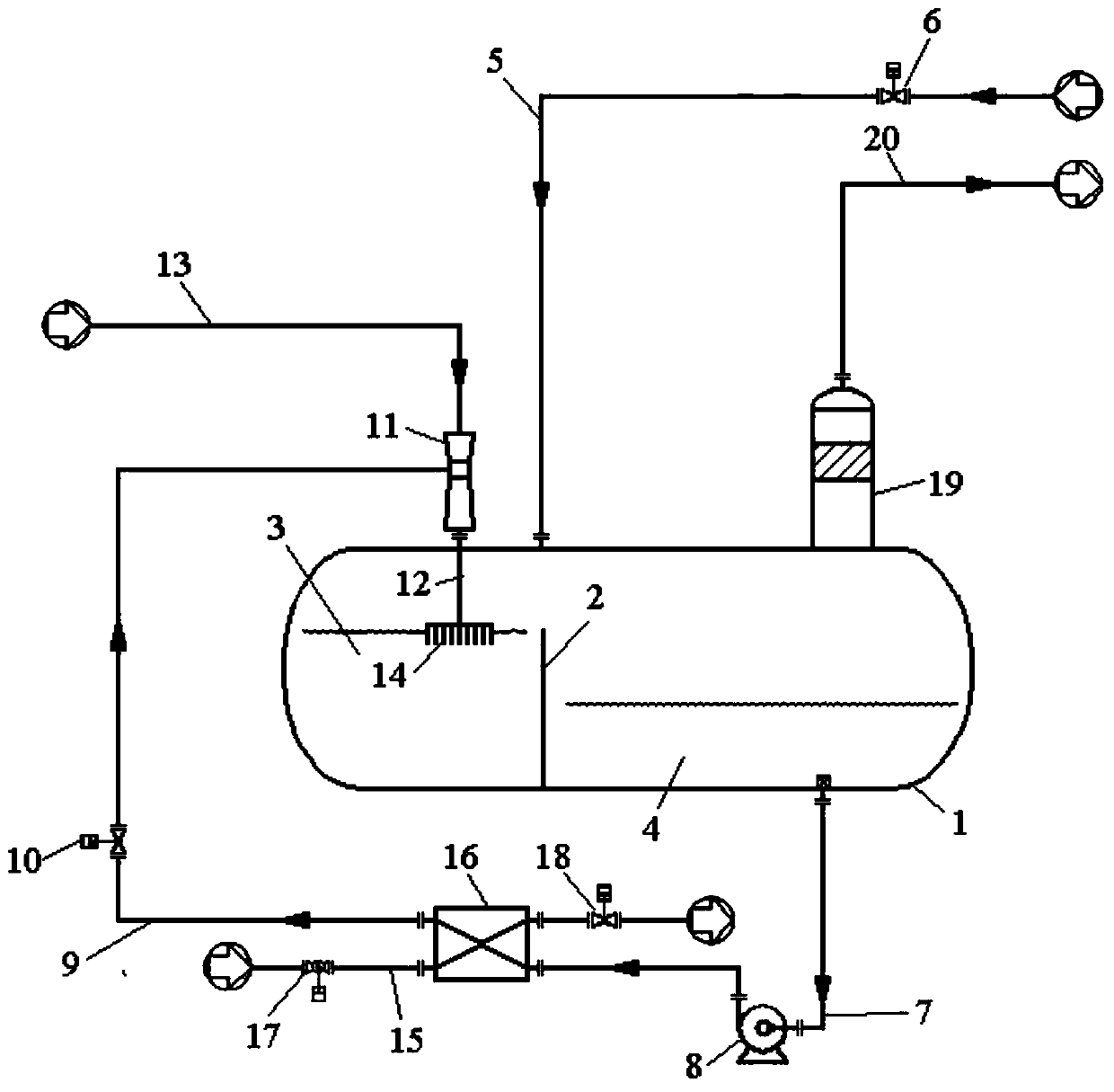

[0094] An exemplary embodiment of the present invention, such as figure 1 As shown, a VOC tail gas water sealing device includes a water sealing device, a backflow device, a cooling device, a water inlet device, an air intake device and an exhaust device.

[0095] The water sealing device includes a water sealing tank 1, a baffle 2 is arranged inside the water sealing tank 1, and the baffle 2 divides the water sealing tank 1 into a first chamber 3 and a second chamber 4, and the first chamber 3 and the second chamber The top of the chamber 4 communicates, but the bottoms of the first chamber 3 and the second chamber 4 do not communicate.

[0096] Further, the liquid level of the sealing liquid in the first chamber 3 is higher than the liquid level of the sealing liquid in the second chamber 4 .

[0097] The water inlet device includes a first water inlet pipe 5 , the first end of the first water inlet pipe 5 communicates with the water seal tank 2 , and the water seal liquid ...

Embodiment 2

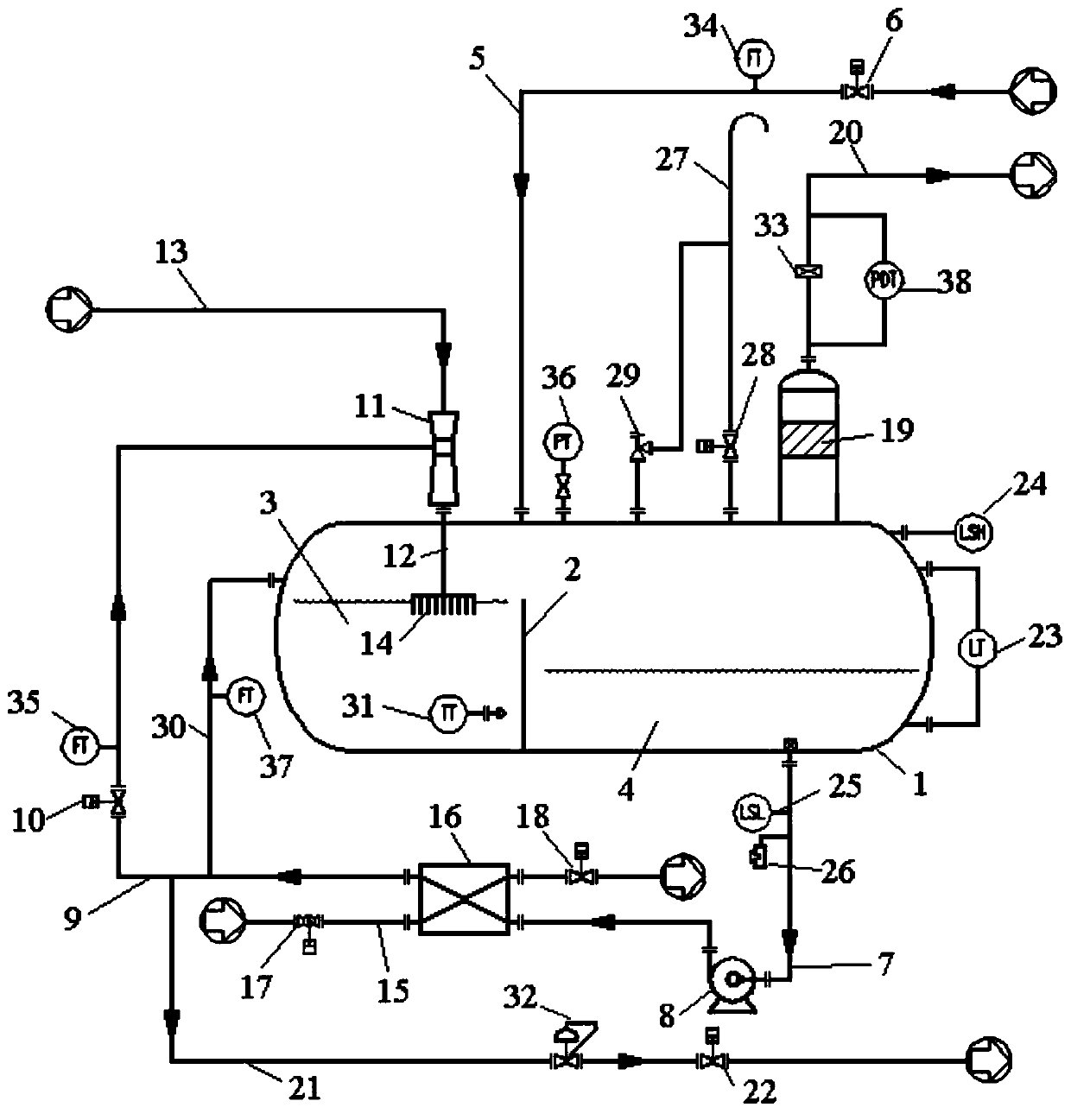

[0125] This embodiment is a preferred embodiment of the present invention, and this embodiment is further optimized on the basis of Embodiment 1.

[0126] Such as figure 2 As shown, the VOC tail gas water sealing device of this embodiment, on the basis of Embodiment 1, further includes: a waste water discharge device, a liquid level control device, a pressure control device, a temperature control device, a fire protection device and multiple transmitters.

[0127] The first water inlet pipe 5 is provided with a second transmitter 34, the second transmitter 34 is located between the first valve 6 and the water seal tank 1, and is used to detect the flow rate of the first water inlet pipe 5 to the water seal tank 1. The flow rate of the sealing fluid, that is, the second transmitter 34 is a flow rate transmitter.

[0128] A third transmitter 35 is arranged on the circulation pipe 9, and the third transmitter 35 is located between the second valve 10 and the vacuum device 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com