Belt wheel cross-ball diameter gauge

A pulley and ball-crossing technology, applied in the direction of mechanical diameter measurement, can solve the problems of low stability of the hand-held school stick, inaccurate measurement results, inconvenient operation, etc., to achieve simple and convenient operation, save labor resources, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

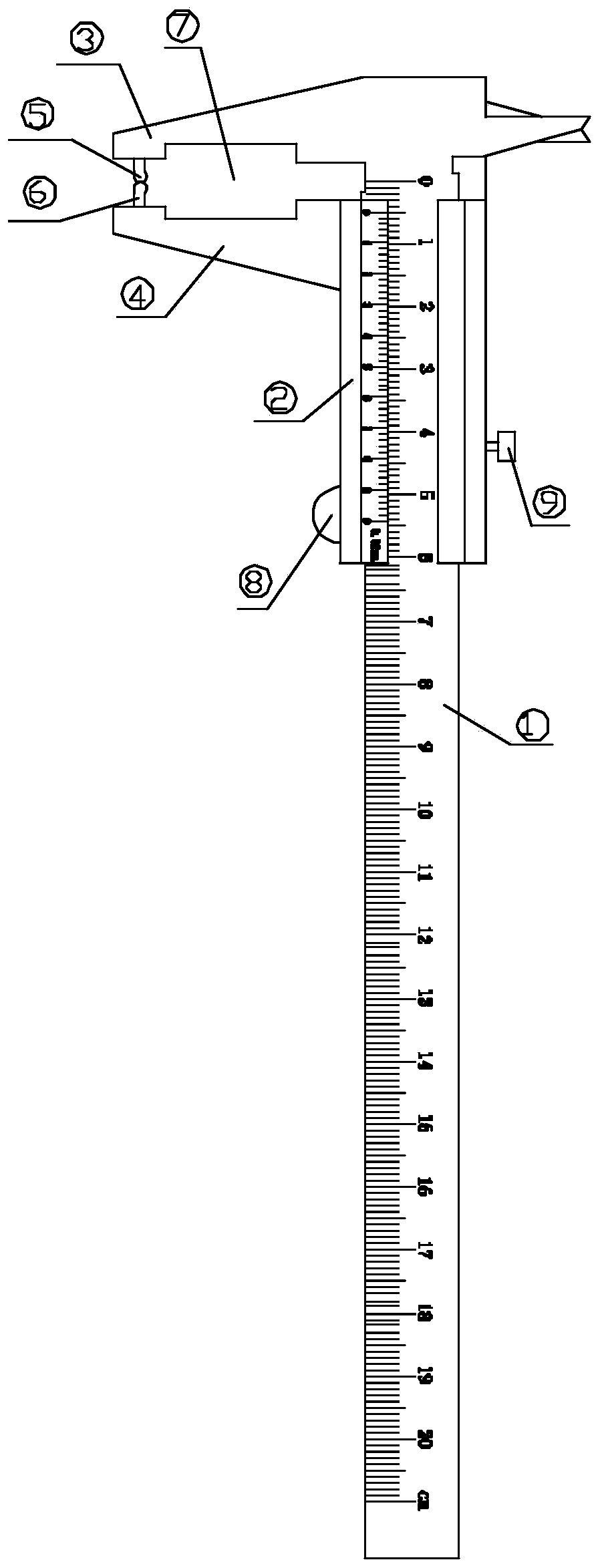

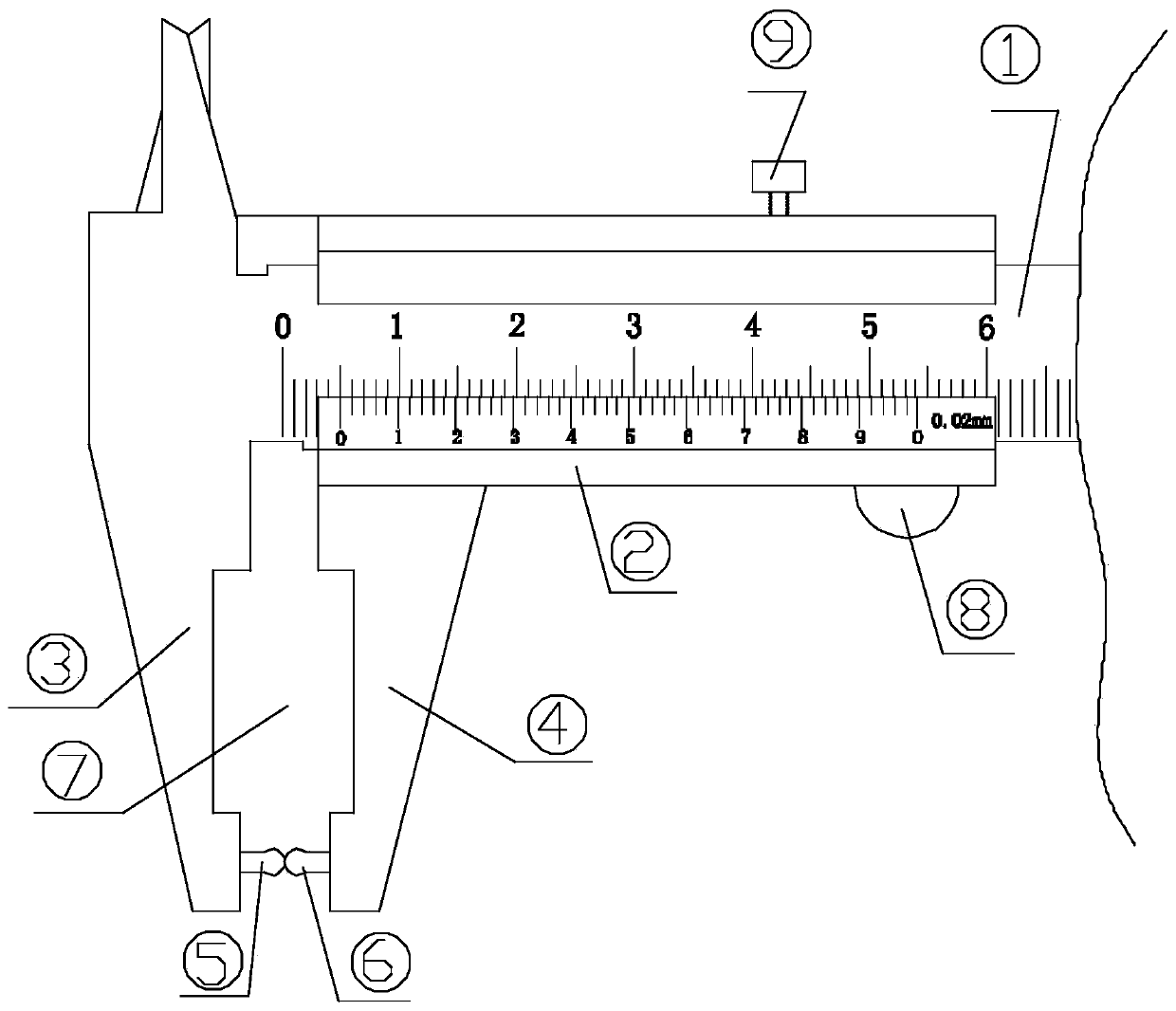

[0022] refer to figure 1 , a belt pulley cross-ball diameter inspection tool proposed by the present invention includes: a main scale 1, a vernier scale 2, a fixed detection arm 3, a moving detection arm 4, a first standard rod 5 and a second standard rod 6.

[0023] The vernier scale 2 is sleeved on the main scale 1 and slidably connected with the main scale 1, and the vernier scale 2 and the main scale 1 form a vernier caliper structure. The fixed detection arm 3 is installed on the main ruler 1 , and the mobile detection arm 4 is installed on the vernier 2 and slides back and forth with the vernier 2 relative to the fixed detection arm 3 . In this way, in this embodiment, the distance between the fixed detection arm 3 and the movable detection arm 4 can be adjusted by sliding the vernier 2 , so that the fixed detection arm 3 and the movable detection arm 4 engage pulleys of different diameters for diameter measurement.

[0024] Specifically, in this embodiment, the fixed d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com