Steel structure hoisting construction method for incineration room and purification room of power plant

A construction method and incineration room technology, which is applied in the hoisting construction of steel structures in purification rooms and incineration rooms in power plants, can solve problems such as unsatisfactory construction period requirements, long cycle times, and high construction costs, so as to reduce transportation costs, shorten construction periods, The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

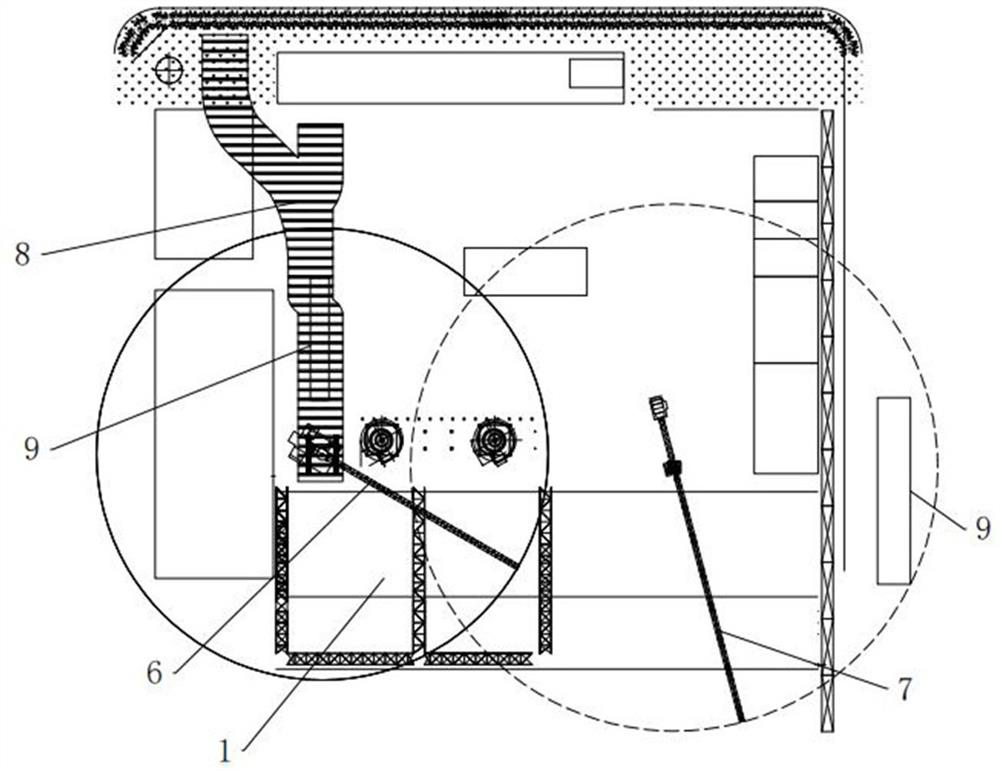

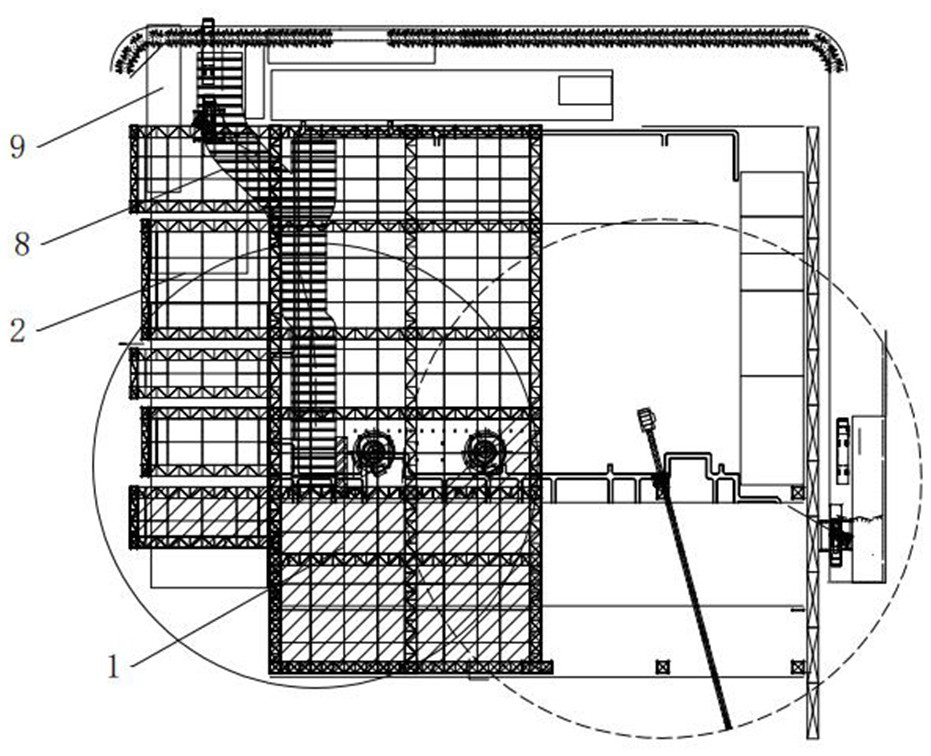

[0038] The steel structure of the incineration room and the purification room of the power plant of the present application includes lattice columns, wall trusses, main trusses, secondary trusses and connecting rods.

[0039] The present invention is a construction method for hoisting a steel structure in an incineration room and a purification room of a power plant, comprising the following steps:

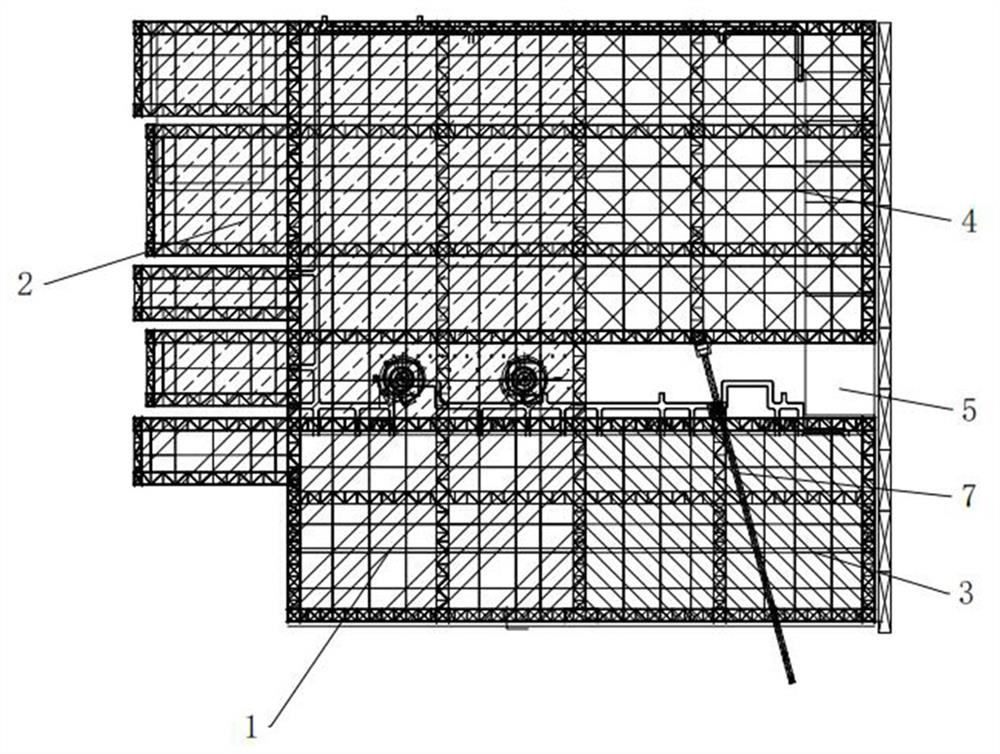

[0040] refer to figure 1 , Step 1: Zoning: According to the lifting performance of the on-site hoisting machinery, the hoisting radius, the equipment construction time, and the tower crane 7 removal time, locate the incineration room area on the west side of the tower crane 7 used for hoisting the incineration room and the purification room equipment. The clean room area on the north side of the room is designated as the second area 2; the area on the south side of the tower crane 7 area is designated as the third area 3, the north area is designated as the fourth area 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com