Sintering brazing gear shifting fixing block and manufacturing method thereof

A fixed block and brazing technology, used in transmission control, components with teeth, belts/chains/gears, etc., can solve the problems of large machining volume, long processing cycle, large processing cost, etc., and achieve convenient production. , The effect of packing convenience and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

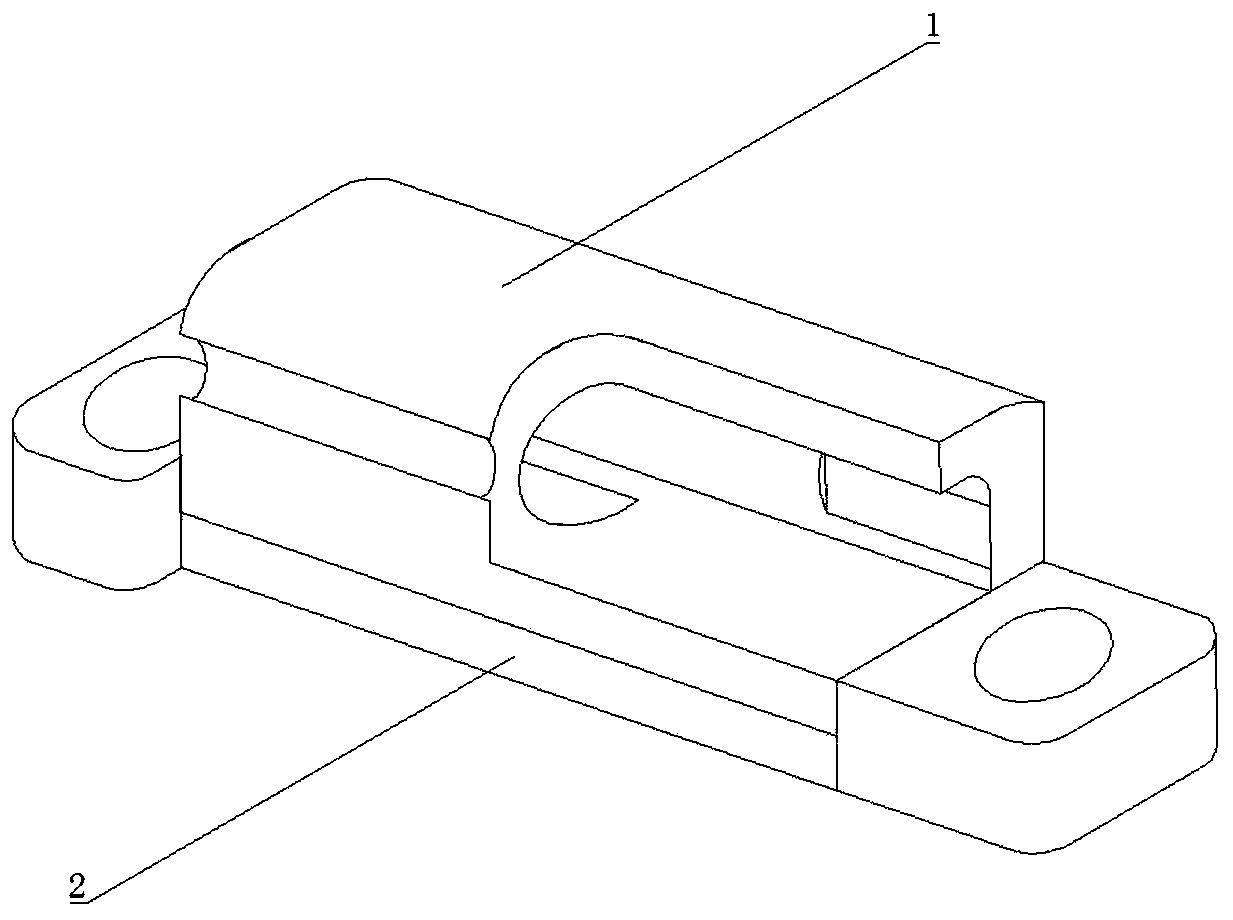

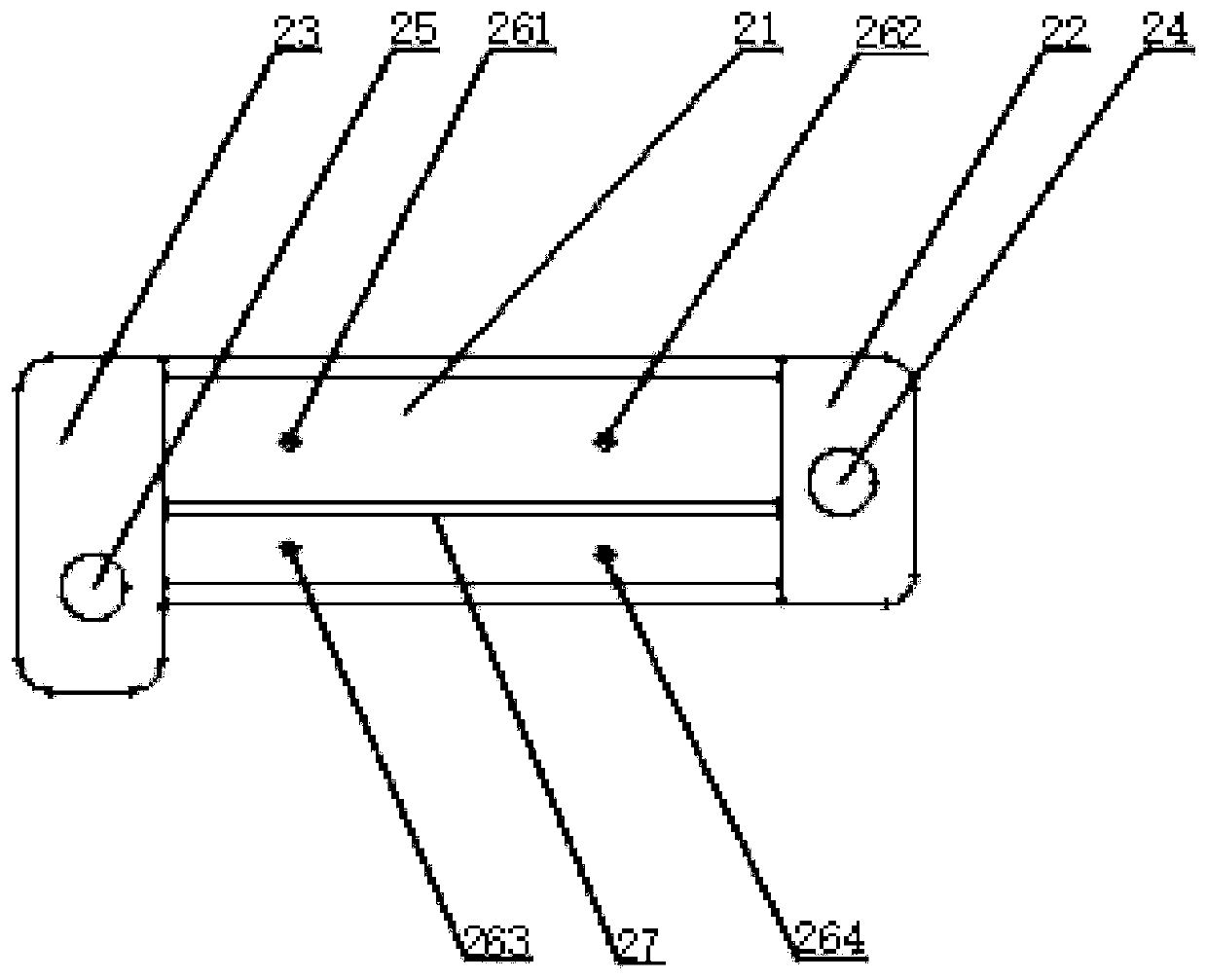

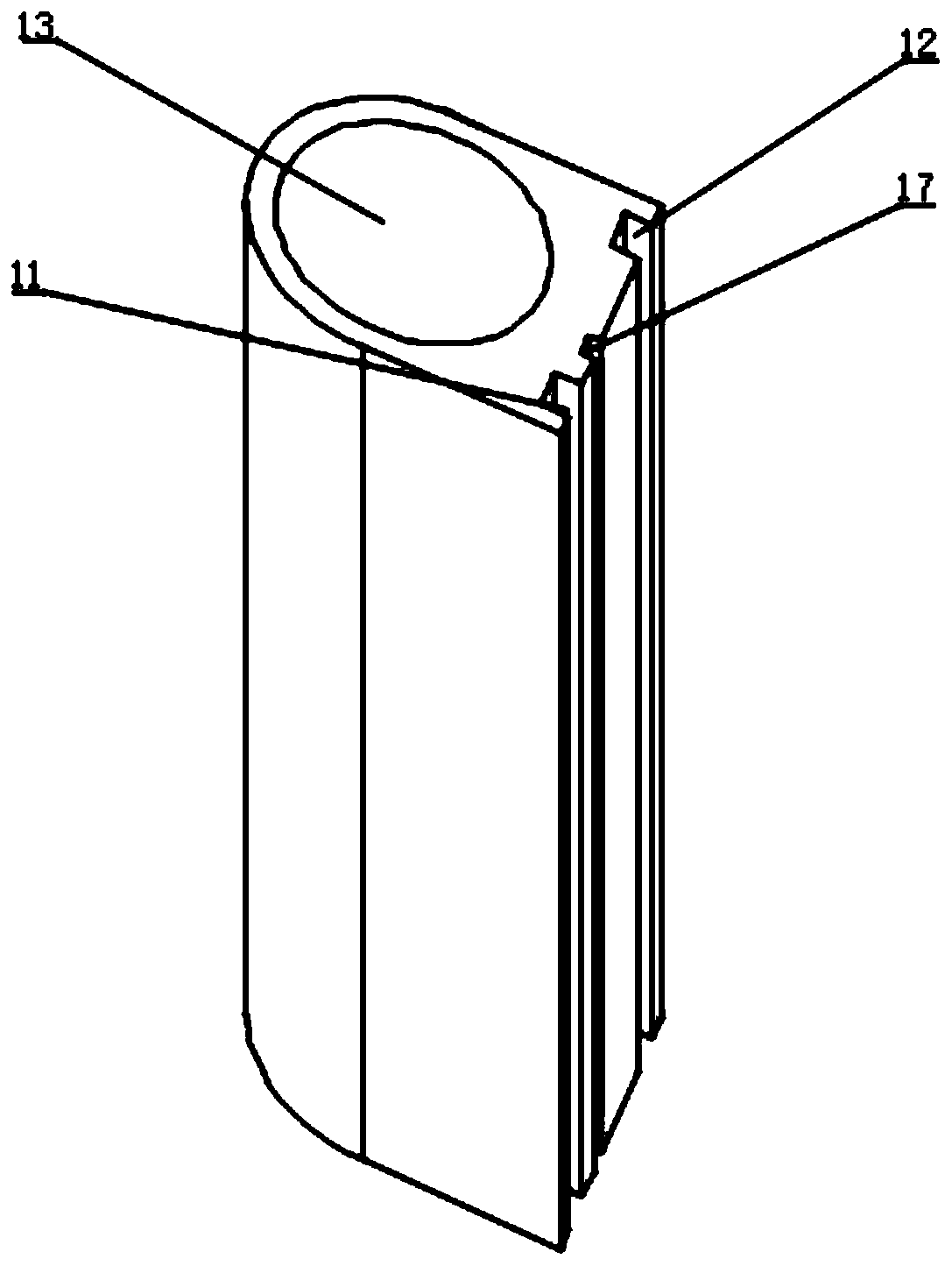

[0024] Example: as attached Figure 1-5 As shown, the sintered brazing shift fixed block is characterized in that it includes a conduit 1 and a base 2, and the base 2 includes a middle plate 21, and the two ends of the middle plate 21 are respectively fixed with a first boss 22 and a second boss. Two bosses 23, the first boss 22 and the second boss 23 protrude toward the same direction, the first boss 22 is provided with a first installation hole 24, and the second boss 23 is provided with The second mounting hole 25, the middle plate 21 is provided with a protrusion, the middle plate 21 is provided with a positioning protrusion 27 along the length direction, the outer surface of the conduit 1 is provided with a solder groove along the length direction, and the solder groove Corresponding to the protrusion, the conduit 1 is provided with a positioning groove 17 corresponding to the positioning protrusion 27, and the conduit 1 is provided with a through hole 13, and the through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com