Gas-liquid two-phase mass flowmeter

A mass flow meter, mass flow technology, applied in the direction of indirect mass flow meter, mass flow measurement device, volume flow measurement device, etc. Large and other problems, to achieve the effect of improving the measurement range and adaptability, and ensuring the reliability of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

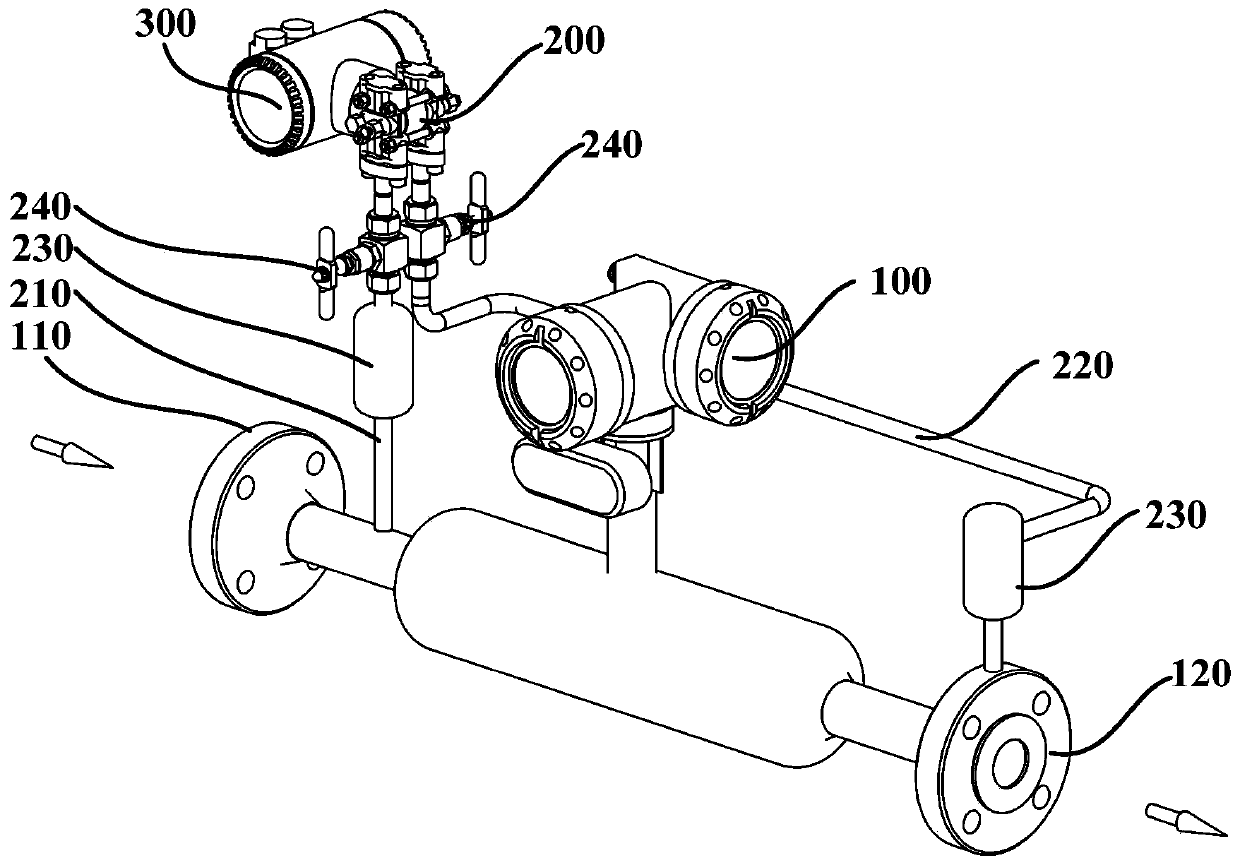

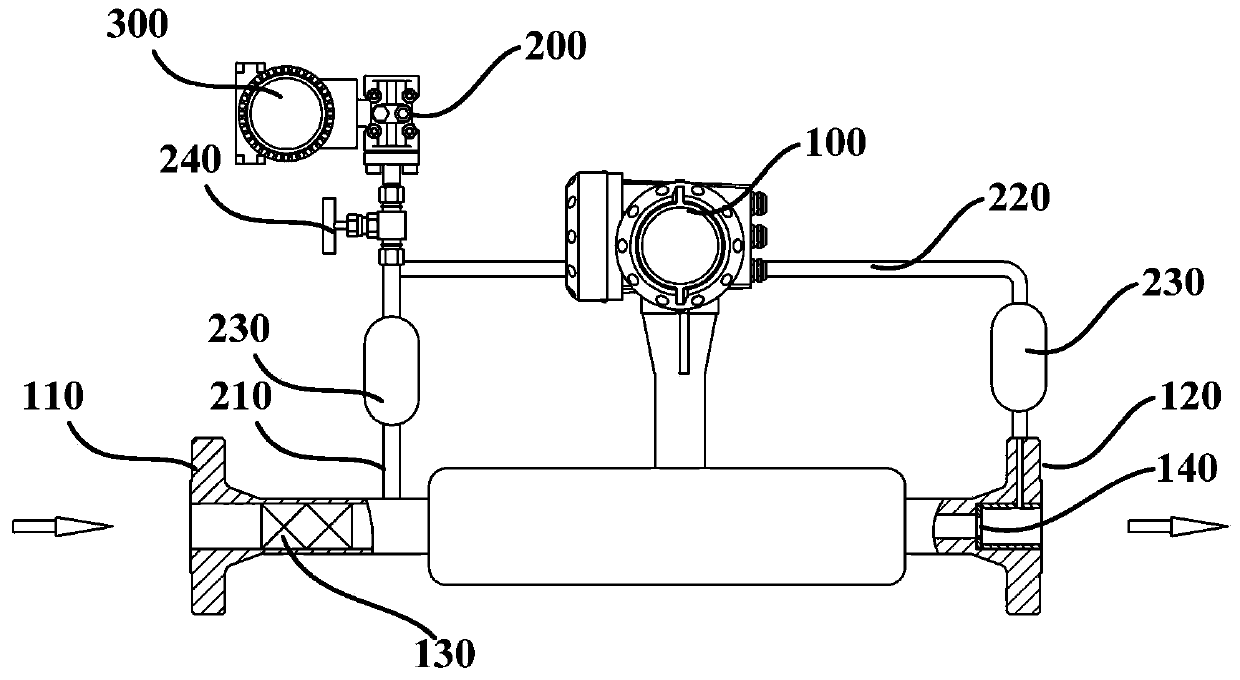

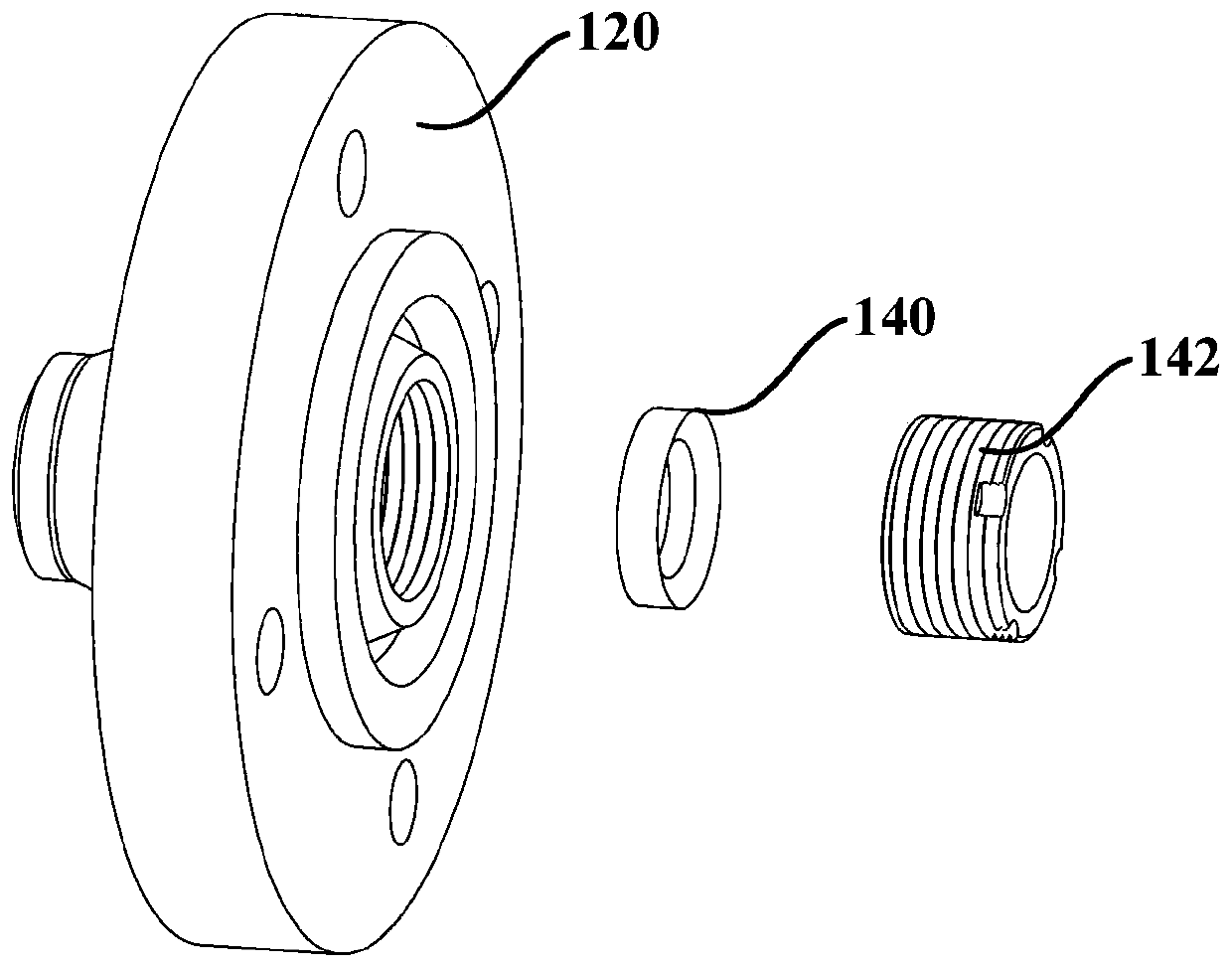

[0027] figure 1 is a schematic structural diagram of a gas-liquid two-phase mass flowmeter according to an embodiment of the present invention. figure 2 is based on figure 1 Schematic of another angle of the gas-liquid two-phase mass flowmeter shown.

[0028] The gas-liquid two-phase mass flowmeter of this embodiment may generally include: a mass flowmeter 100 , a pressure differential pressure composite sensor 200 , and a flow computer 300 .

[0029] The mass flow meter 100 is connected to the pipeline of the measured gas-liquid two-phase fluid, and is used to measure the temperature, mass flow rate and mixed density of the measured gas-liquid two-phase fluid.

[0030] The pressure differential pressure composite sensor 200, its differential pressure positive pressure pipe 210 and differential pressure negative pressure pipe 220 are respectively connected to the upstream pipeline and the downstream pipeline of the mass flow meter 100, and are used to measure the measured g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com