Device and method for evaluating abrasion resistance of bearing retainer

A bearing cage and wear resistance technology, applied in the field of tribology, can solve the problems of long evaluation time and inconsistent evaluation indicators, and achieve the effects of short evaluation time, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

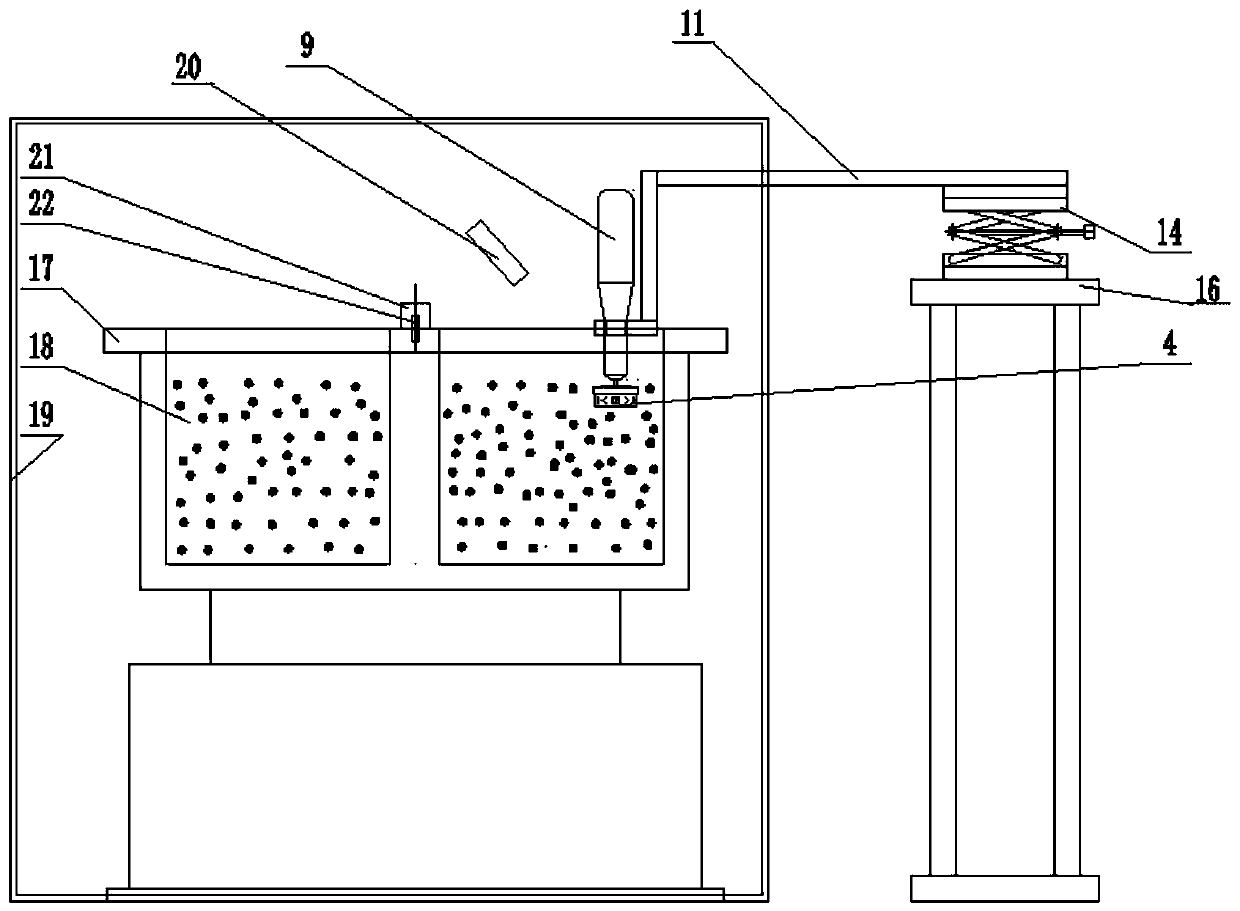

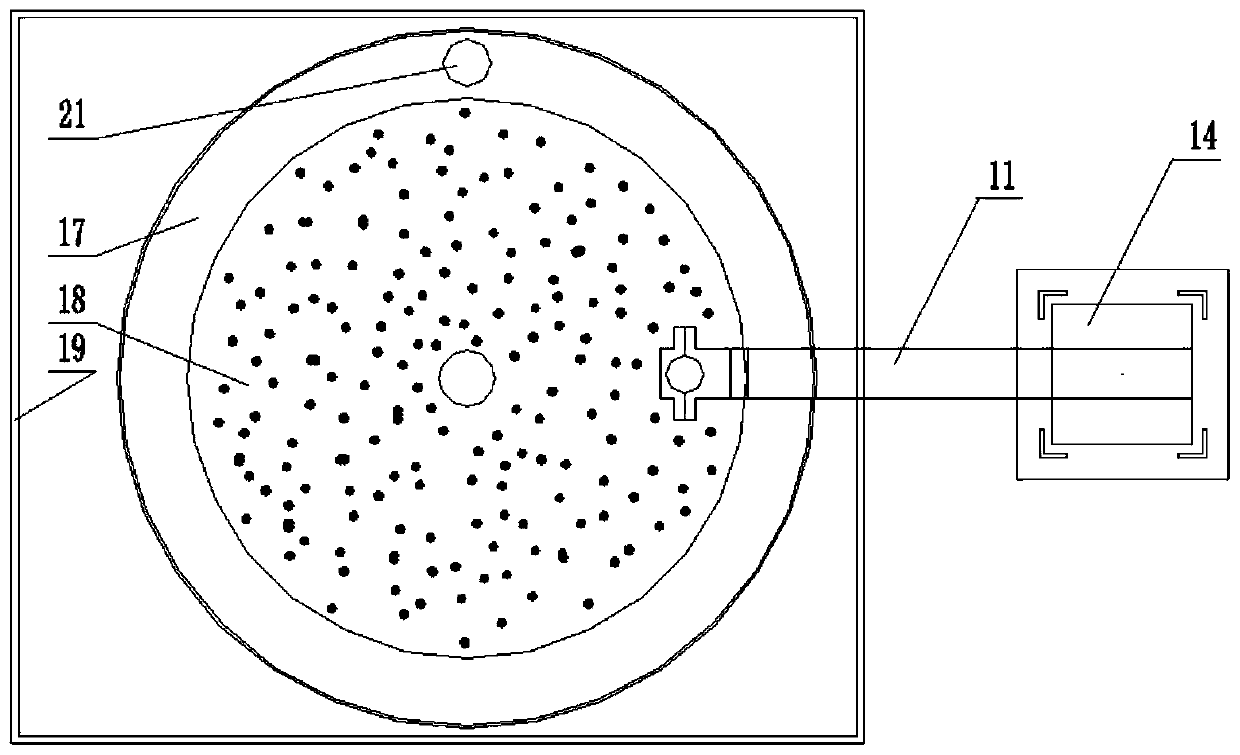

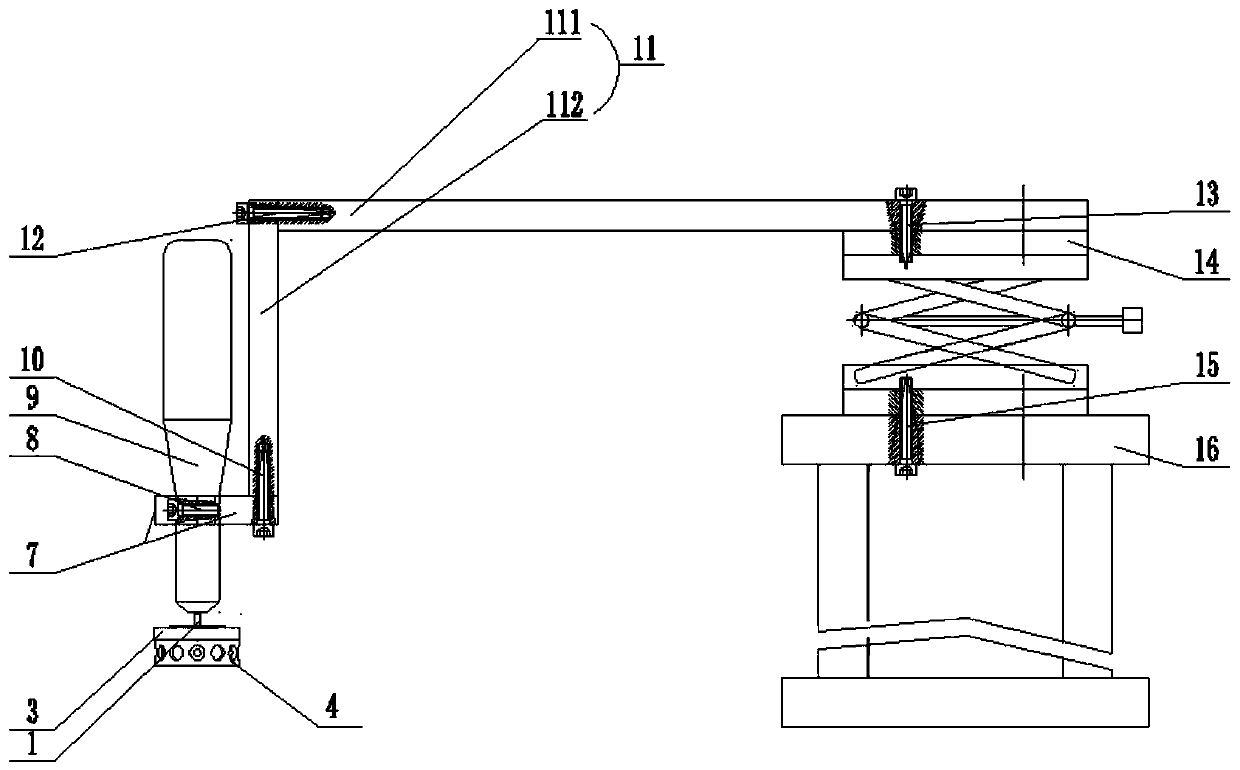

[0056] A method for evaluating the wear resistance of a bearing cage using the above-mentioned device for evaluating the wear resistance of a bearing cage includes the following steps:

[0057] Step 1. Add 10-18 mesh white corundum abrasives into the frequency conversion vibrator;

[0058] Step 2. Weigh the mass of the bearing cage to be tested. The polyimide cage used is used. The measurement accuracy of the microcrystalline balance for measuring the cage should be 0.001g. The cage to be tested is measured 3 times, and the obtained The average weight is 2.1302g; then fix the bearing cage to be tested on the motor shaft of the motor through the cage fixture; fix the motor on the lifting platform through the motor fixture and L-shaped cantilever; paste reflective paper on the back of the cage fixture , used to measure the cage speed;

[0059] Step 3. Completely immerse the bearing cage into the abrasive material of the frequency conversion vibrator through the lifting platform...

Embodiment 2

[0063] A method for evaluating the wear resistance of a bearing cage using the above-mentioned device for evaluating the wear resistance of a bearing cage includes the following steps:

[0064] Step 1. Add 10-18 mesh white corundum abrasives into the frequency conversion vibrator;

[0065] Step 2. Weigh the mass of the bearing cage after the experiment of Example 1 is completed. The measurement accuracy of the microcrystalline balance for measuring the cage should be 0.001g. The cage to be tested is measured 3 times, and the average weight obtained is 2.0421g; Then fix the bearing cage to be tested on the motor shaft of the motor through the cage fixture; fix the motor on the lifting platform through the motor fixture and L-shaped cantilever; stick reflective paper on the back of the cage fixture for measuring the cage Rotating speed;

[0066] Step 3. Completely immerse the bearing cage into the abrasive material of the frequency conversion vibrator through the lifting platfo...

Embodiment 3

[0070] A method for evaluating the wear resistance of a bearing cage using the above-mentioned device for evaluating the wear resistance of a bearing cage includes the following steps:

[0071] Step 1. Add 10-18 mesh white corundum abrasives into the frequency conversion vibrator;

[0072] Step 2. Weigh the mass of the bearing cage after the experiment of Example 2 is completed. The measurement accuracy of the microcrystalline balance for measuring the cage should be 0.001g. The cage to be tested is measured 3 times, and the average weight obtained is 1.9725g; Then fix the bearing cage to be tested on the motor shaft of the motor through the cage fixture; fix the motor on the lifting platform through the motor fixture and L-shaped cantilever; stick reflective paper on the back of the cage fixture for measuring the cage Rotating speed;

[0073] Step 3. Completely immerse the bearing cage into the abrasive material of the frequency conversion vibrator through the lifting platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com