A milling stability domain prediction method using Newton and Hermite interpolation methods

A technology of Hermitian interpolation and forecasting methods, applied in special data processing applications, instruments, complex mathematical operations, etc., can solve problems such as large amount of calculation, calculation accuracy and calculation efficiency cannot be improved at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The drawings constituting a part of the present invention are used to provide a further understanding of the present invention, and the schematic embodiments of the present invention and their descriptions are used to explain the present invention, and do not constitute an improper limitation of the present invention.

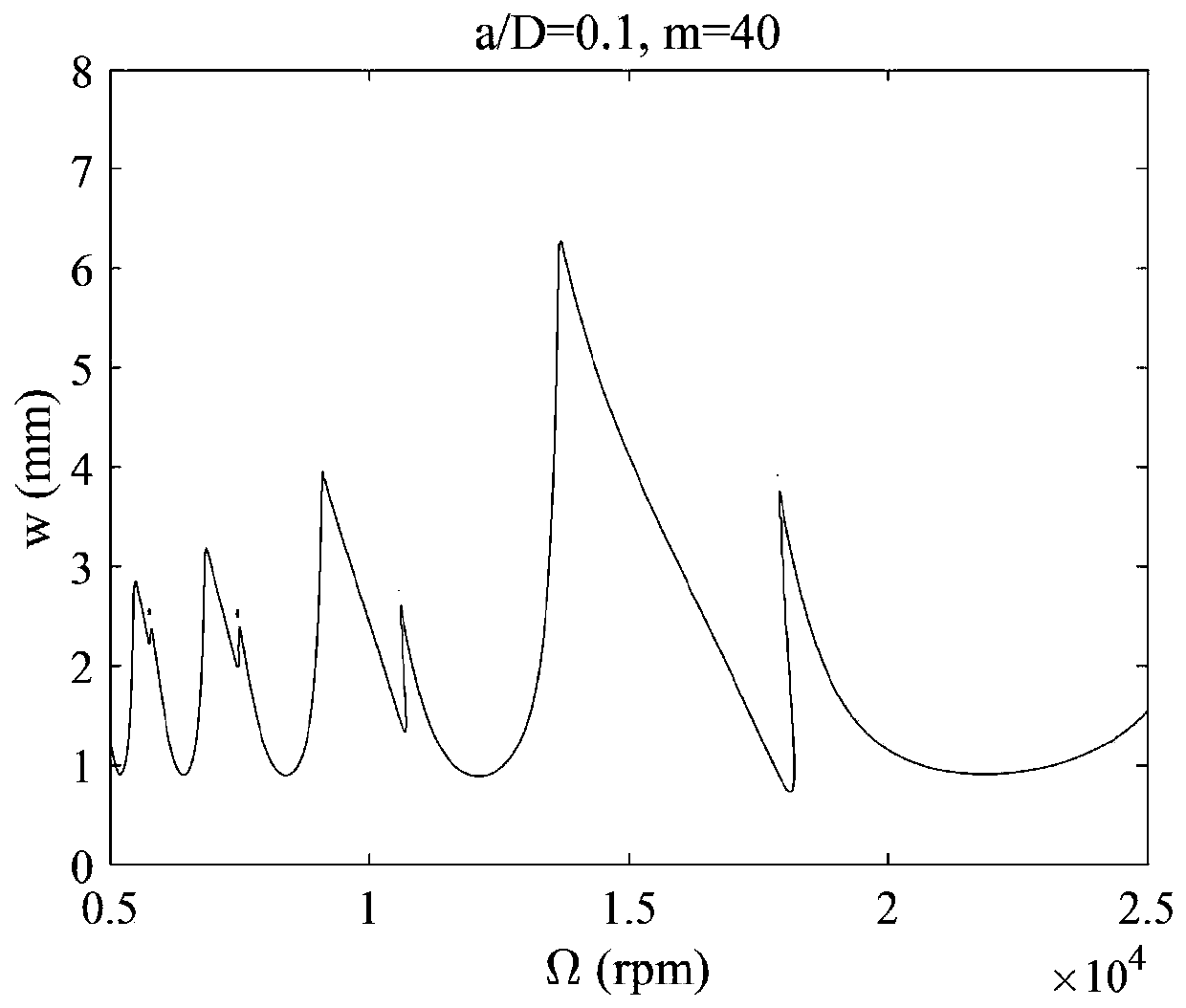

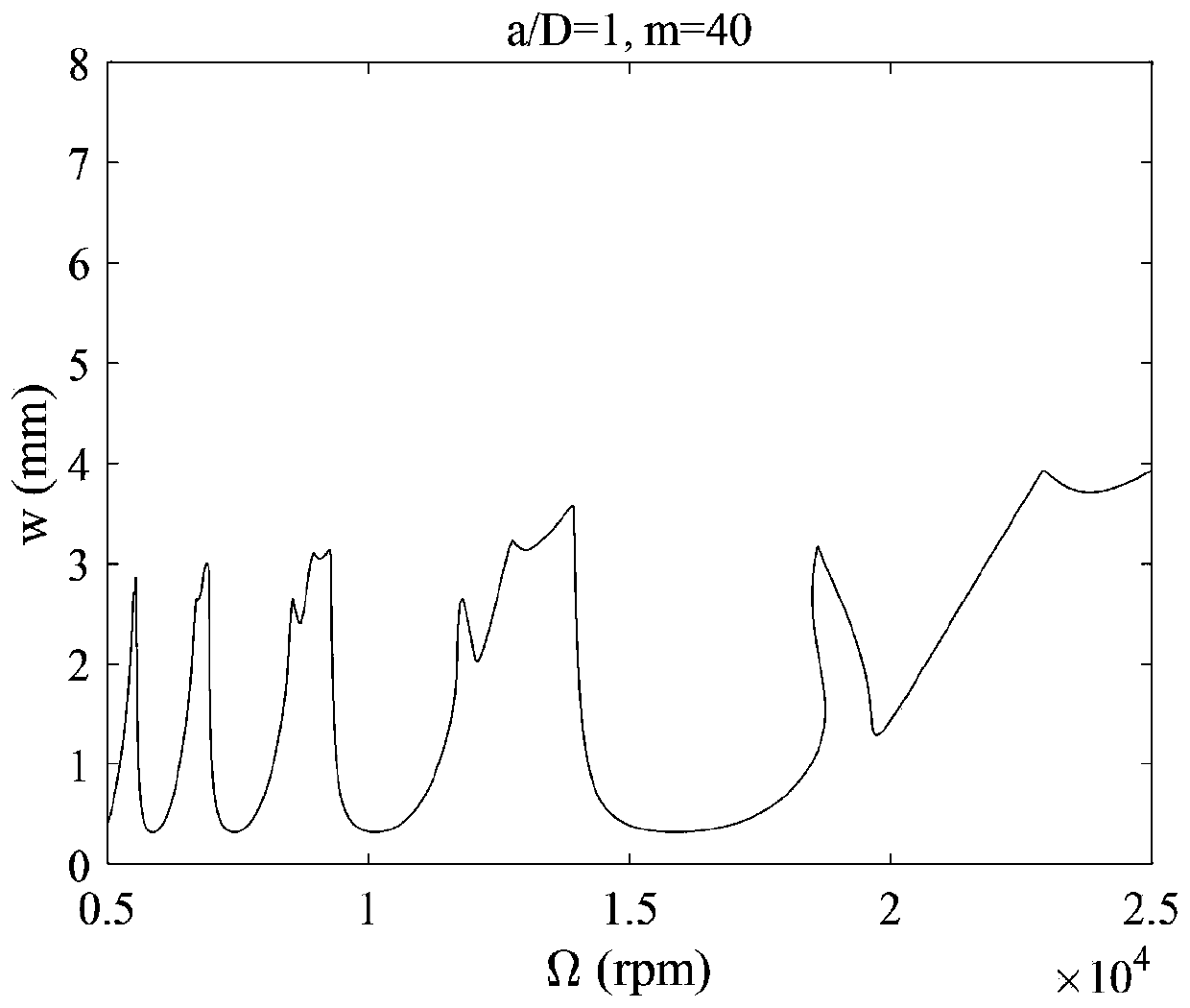

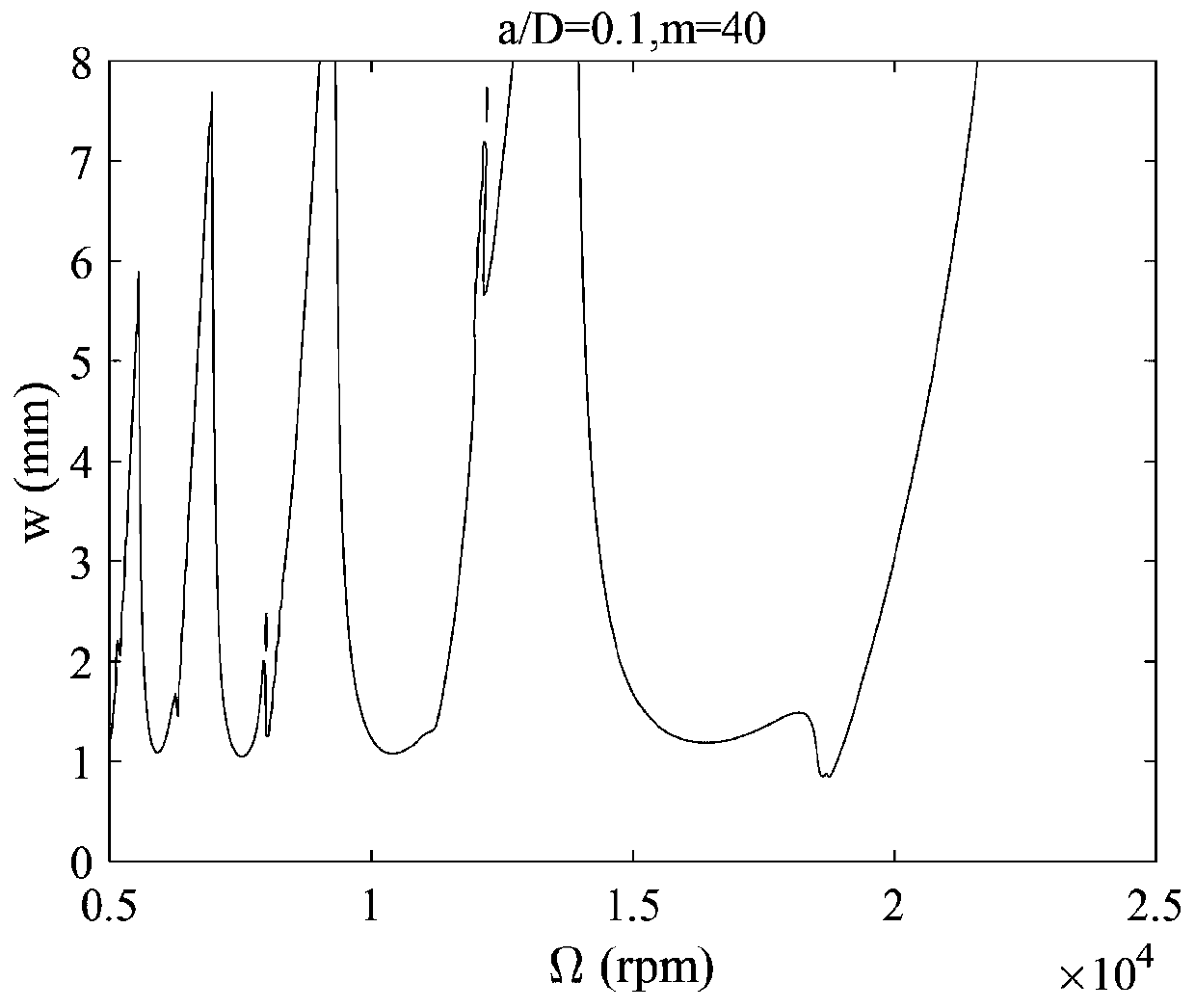

[0089] Such as Figure 7 As shown, the present invention provides a milling stable domain prediction method utilizing Newton and Hermitian interpolation method, the method specifically includes the following steps;

[0090] Step 1: Construct the time-delay differential equation considering the dynamics of single-degree-of-freedom regenerative chatter milling, as shown in Equation 22:

[0091]

[0092] Among them, ζ, ω n 、m t, w and q(t) are the damping ratio, natural frequency, mass, axial depth of cut and coordinates of the tool, respectively, is the first derivative of q(t), is the second derivative of q(t), h(t) represents the cutting force c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com