Ultrasonic image probe cleaning device

A cleaning device and ultrasonic imaging technology, applied to water supply devices, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of low medical efficiency, poor wiping effect, cumbersome operation of manual wiping probes, etc., and achieve simple structure, Time-saving and highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

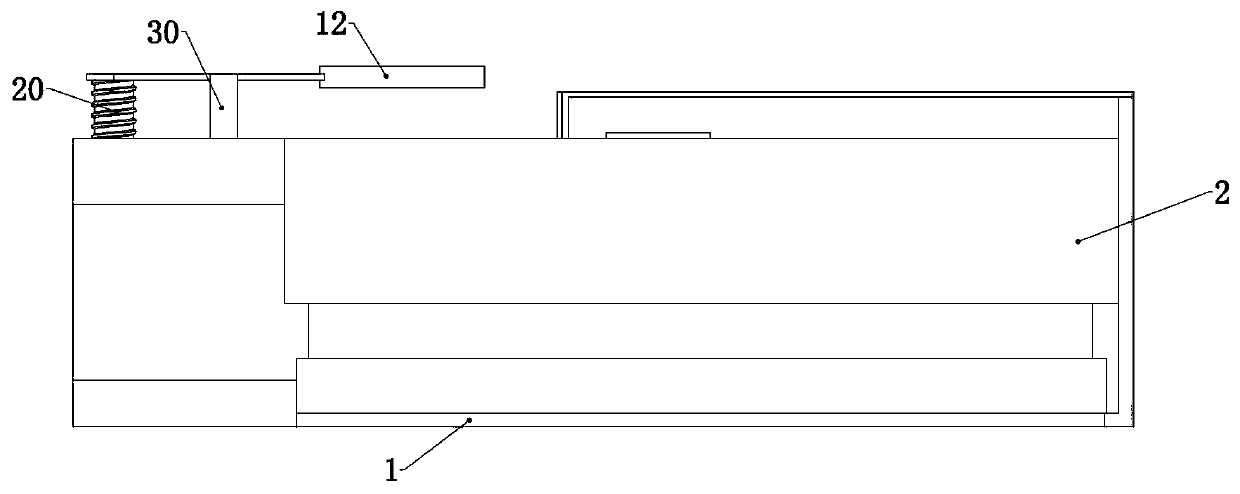

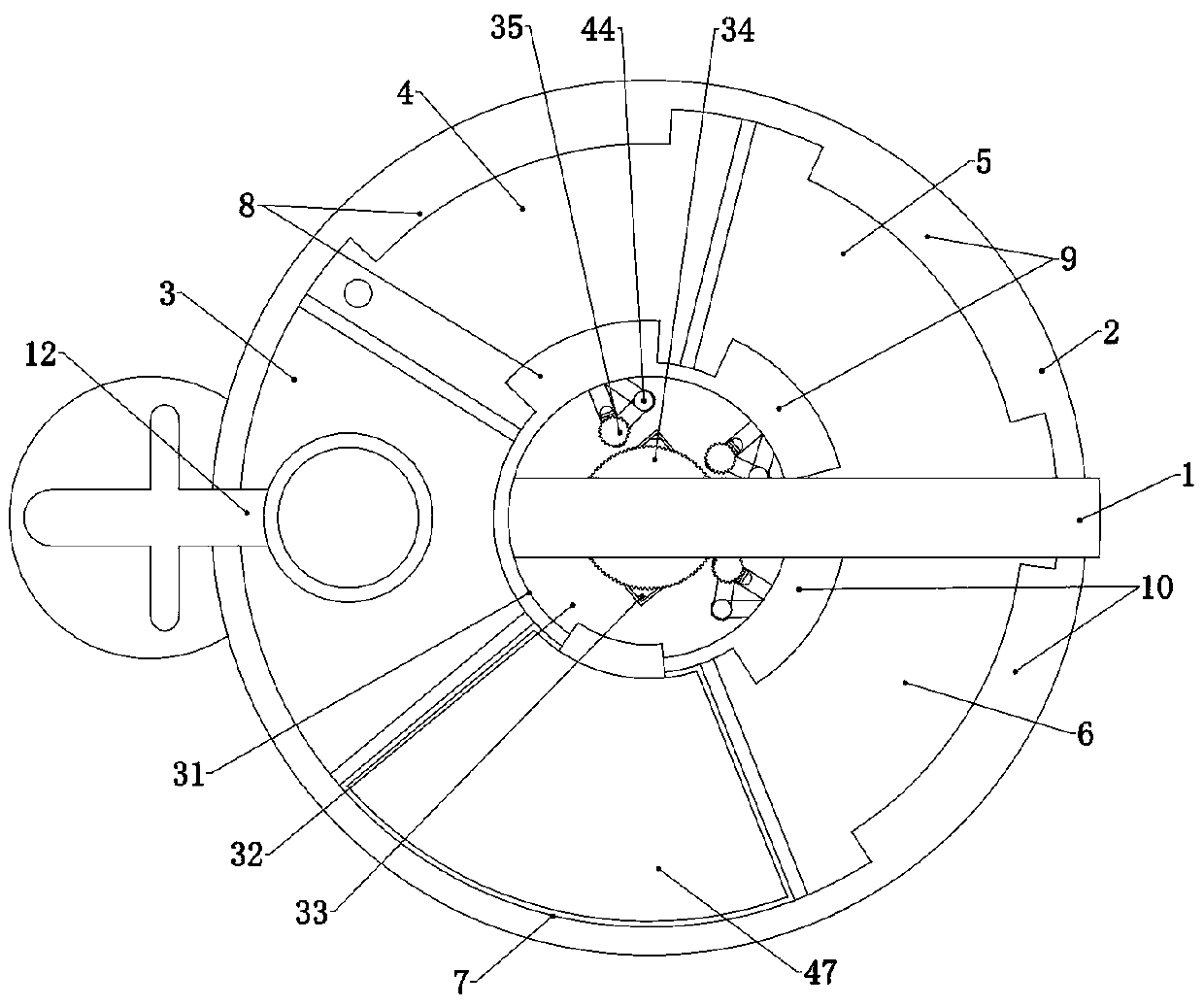

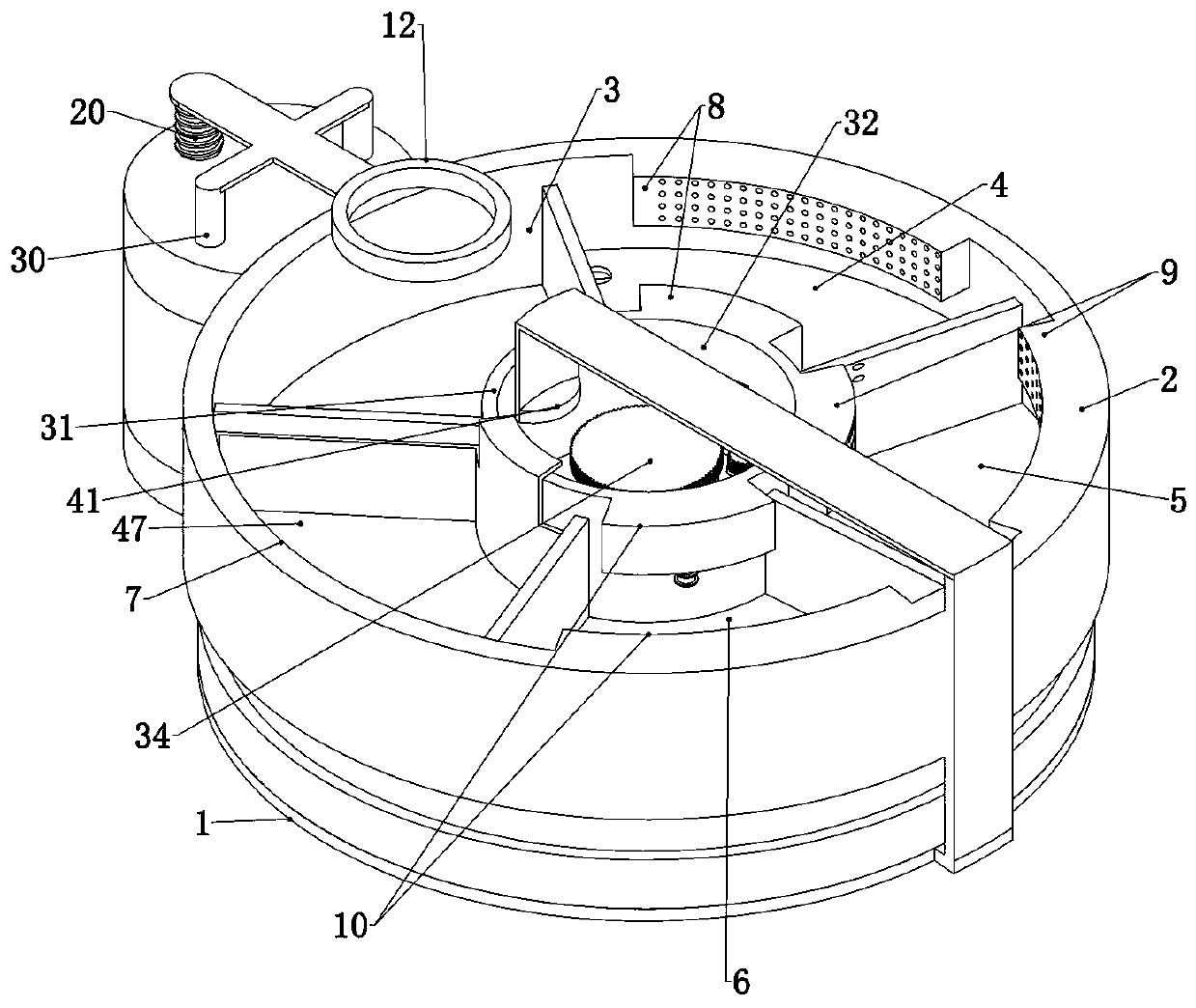

[0034]Embodiment 1, the present invention is an ultrasonic image probe cleaning device, which is characterized in that it includes a main body 1, the main body 1 can be placed on a desktop to provide a fixed basis for subsequent structures, and the main body 1 is rotatably connected to the device. The hollow topless turntable 2, the turntable 2 is evenly divided into five areas and is divided into a waiting area 3, a disinfection and cleaning area 4, a drying area 5, a sterilization area 6, and a liquid dip area 7. The disinfection and cleaning area 4 is fixedly connected with a spray device 8, the drying area 5 is fixedly connected with a dryer 9, and the sterilization area 6 is fixedly connected with a sterilization device 10. Waiting area 3 is used for daily placement of probes. It is a hollow shell without debris, and a collection box is also detachably installed inside it to collect the couplant left on the probe. The above-mentioned disinfection and cleaning area 4 is us...

Embodiment 2

[0035] Embodiment 2, on the basis of Embodiment 1, this embodiment provides a specific periodic lifting device 13, so that the probe support 12 can realize periodic cyclic lifting motion. Specifically, the periodic lifting device 13 includes and The lift drive gear 16 connected to the drive motor 14, specifically, the lift drive gear 16 is coaxially and fixedly connected to the output shaft of the drive motor 14, and the drive motor 14 works to drive the drive motor 14. The lift drive gear 16 rotates to serve as the power source of the periodic lift device 13. The lift drive gear 16 is meshed with a lift relay gear 17 rotatably connected to the main body 1. The lift relay gear 17 A lifting incomplete gear 18 is fixedly connected coaxially, and a threaded sleeve 19 rotatably connected to the main body 1 is meshed beside the lifting incomplete gear 18 . The screw 20 on the main body 1, the threaded sleeve 19 is a hollow cylinder rotatably connected to the main body 1, the inner ...

Embodiment 3

[0037] Embodiment 3, on the basis of Embodiment 1 or Embodiment 2, this embodiment provides a specific way of driving the motor 14 to drive the turntable 2 to rotate, so that the rotation of the turntable 2 is changed to intermittent rotation, and can match the periodicity of the probe holder 12. Specifically, the lower end of the drive motor 14 is connected to the power drive pulley 26 rotatably connected to the main body 1. Specifically, the power drive pulley 26 is coaxially and fixedly connected to the drive motor. 14 on the output shaft, refer to Figure 5 , Figure 7 It can be seen that the lift drive gear 16 and the power drive pulley 26 are located at the upper and lower ends of the drive motor 14, respectively. Therefore, the drive motor 14 should use a bidirectional output shaft motor. In fact, a conventional motor is used and the motor is placed in The device is at the bottom and the lifting drive gear 16 and the power driving pulley 26 are both coaxially and fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com