Machining method for controlling deformation of high-precision and high-temperature alloy thin-walled dual-wing mounting edge disk part

A high-temperature alloy and processing method technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as affecting the qualified delivery of workpieces, and achieve the effect of improving the level of manufacturing technology and far-reaching economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

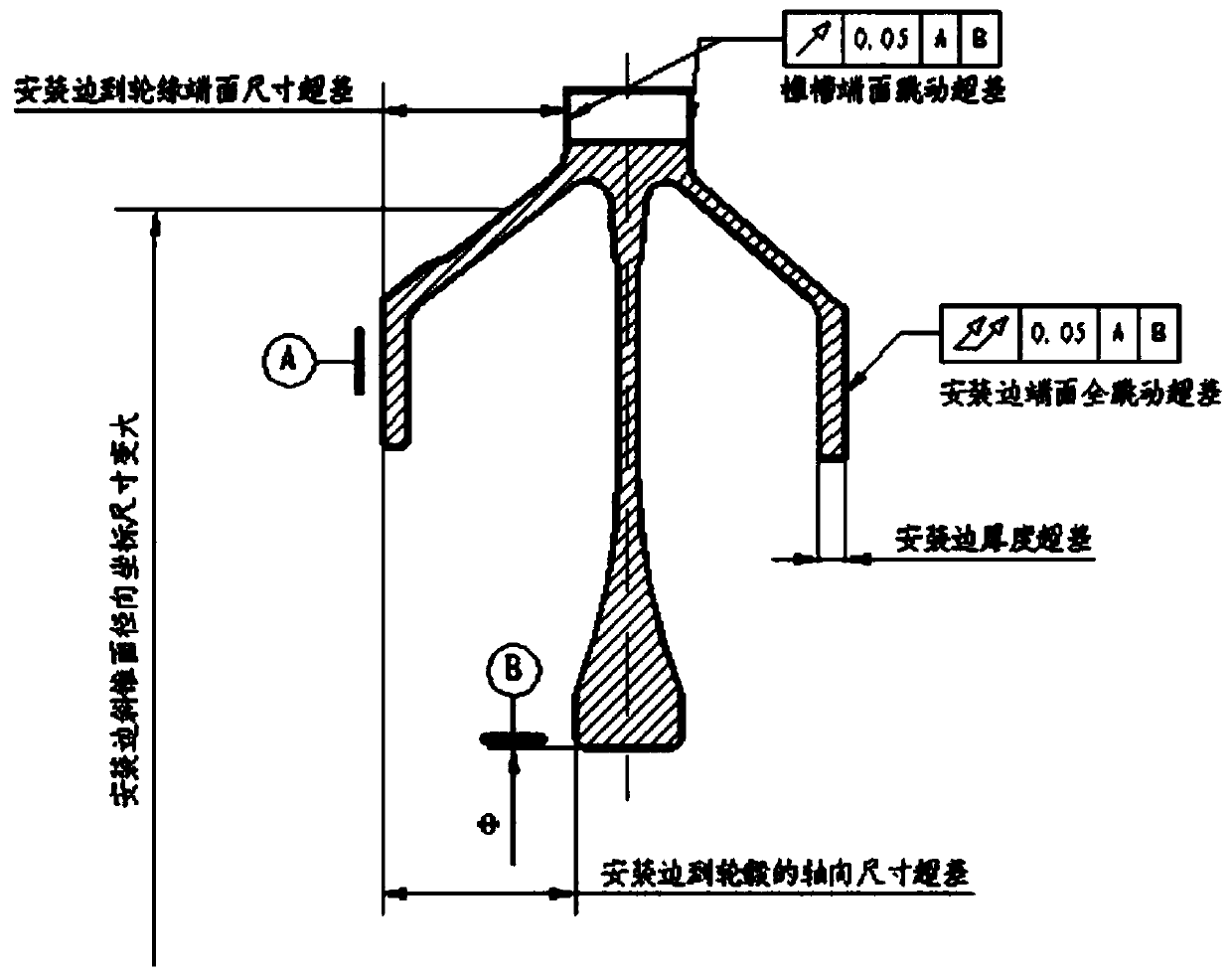

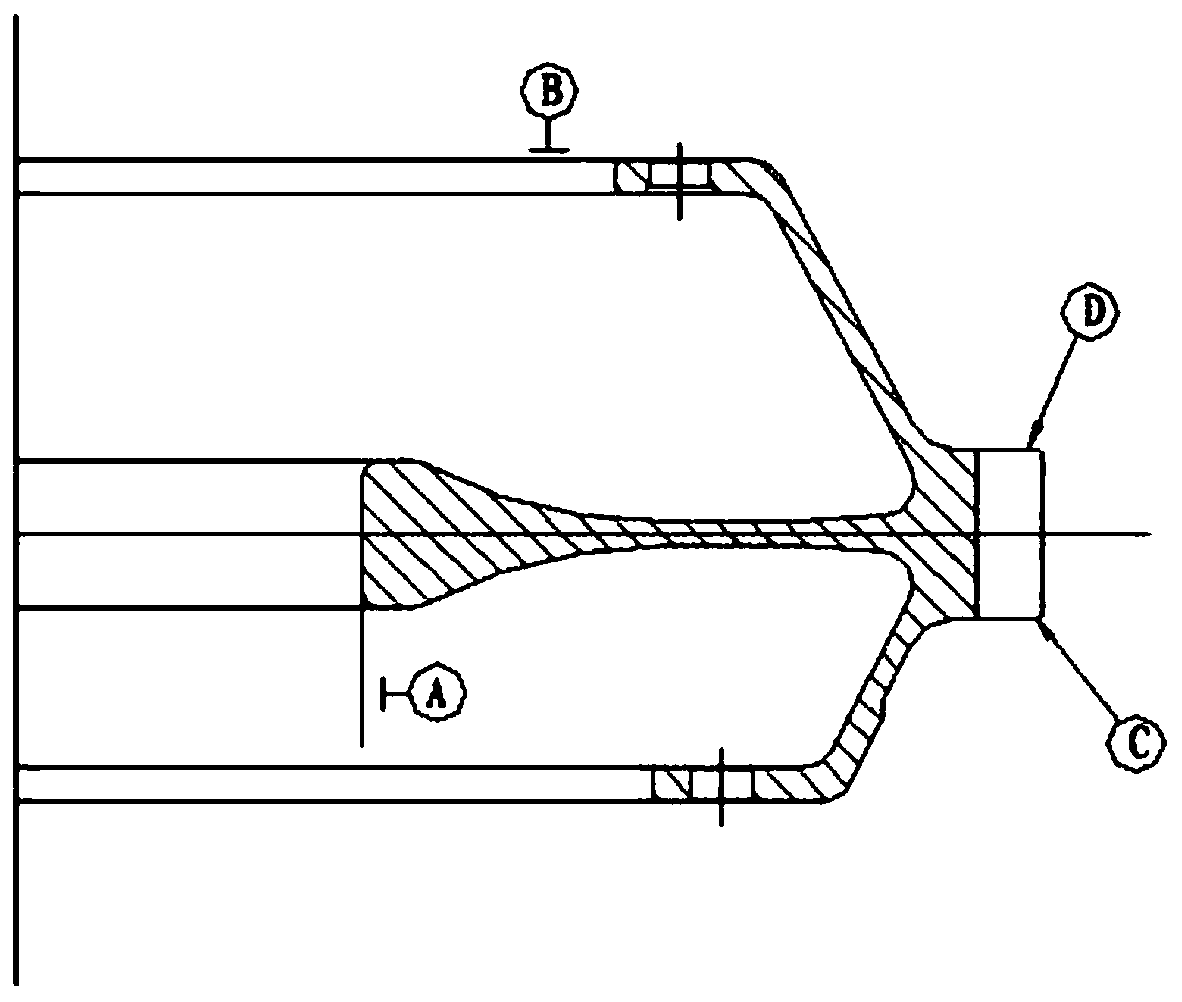

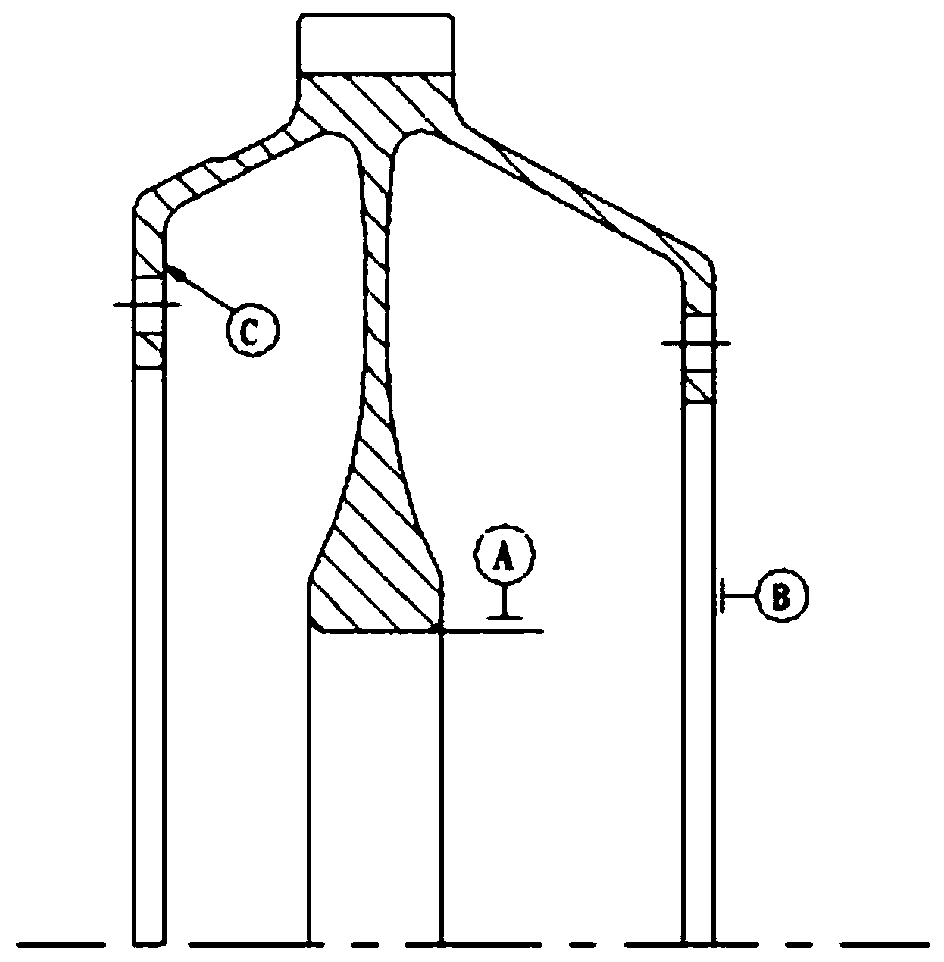

[0070] The invention provides a processing method for controlling deformation of a high-precision superalloy thin-walled double-wing mounted side plate, which is characterized in that: specifically,

[0071] 1. Process route control of workpiece deformation

[0072] Determine the process plan: Because the workpiece is a thin-walled part, it is necessary to consider controlling deformation when starting to formulate the process route.

[0073] The process route is rough turning→fine turning→finish turning→marking, cleaning→intermediate inspection→stress relief heat treatment→fluorescent inspection→grinding→rim end turning→shot peening→grinding after shot peening to repair the end face, rough turning removal The margin is large and the processing stress is large, which has a great impact on the subsequent processing of the workpiece; the finishing process is arranged according to the traditional process, and the deformation cannot be effectively corrected; the repair process is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com