A kind of organosilicon composition for encapsulation of purple LED and preparation method thereof

An LED packaging and silicone technology, applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc. Excellent UV resistance and aging resistance, good compatibility and stability, and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Preparation of benzophenone UV-absorbing polysiloxane

[0029] In a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, add 21.4g of 2,4-dihydroxybenzophenone, 1g of calcium carbonate and 40g of deionized water in sequence, and heat up to 80°C while stirring with nitrogen gas , then add 11.4g allyl glycidyl ether dropwise, react for 3 hours, cool to room temperature, adjust the pH to 6.6 with dilute hydrochloric acid, extract with benzene, filter, wash with water, and remove low boiling substances under reduced pressure to obtain transparent Viscous liquid: Take 16.4g of the above viscous liquid and put it into a three-necked bottle, add 30g of phenyl hydrogen-containing silicone oil and 50mL of toluene solvent, stir, heat up to 62°C, add dropwise 0.1g of platinum catalyst (chloroplatinic acid-tetramethyl Divinyldisiloxane complex, the content of platinum is 5000ppm), after 4 hours of reaction at a temperature of 80°C, filter, was...

Embodiment 2

[0032] Example 2 Preparation of benzophenone UV-absorbing polysiloxane

[0033] In a three-necked flask equipped with a stirrer, a thermometer and a reflux condenser, add 21.4g of 2,4-dihydroxybenzophenone, 1g of calcium carbonate and 40g of deionized water in sequence, and heat up to 80°C while stirring with nitrogen gas , then add 11.4g allyl glycidyl ether dropwise, react for 3 hours, cool to room temperature, adjust the pH to 6.3 with dilute hydrochloric acid, extract with benzene, filter, wash with water, and remove low boiling substances under reduced pressure to obtain transparent Viscous liquid: Take 16.4g of the above viscous liquid into a three-necked bottle, add 30g of phenyl hydrogen-containing silicone oil and 50mL of toluene solvent, stir, heat up to 60°C, add dropwise 0.1g of platinum catalyst (alcoholic solution of chloroplatinic acid, The content of platinum is 4000ppm), and the reaction temperature is controlled at 80°C for 4 hours, filtered, washed with wate...

Embodiment 3

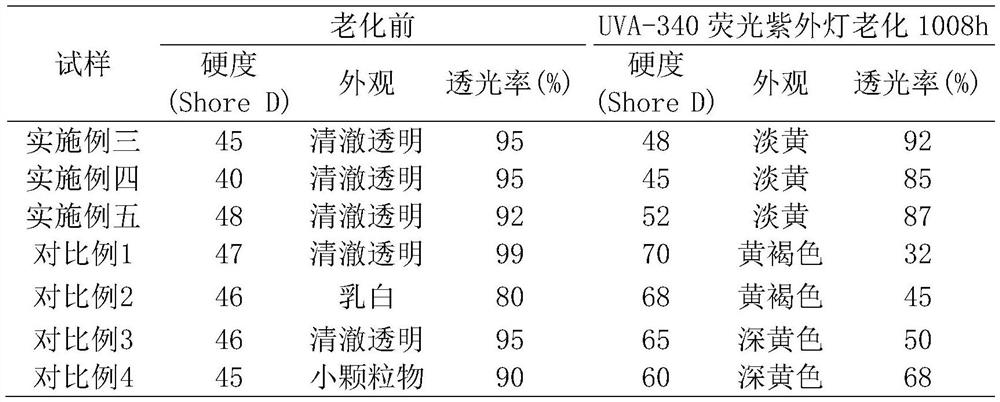

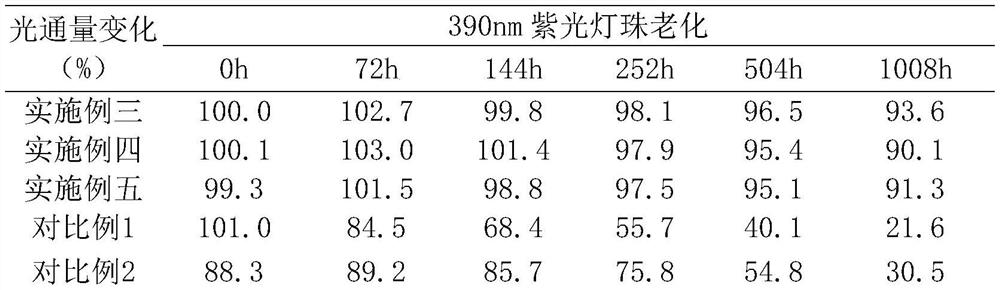

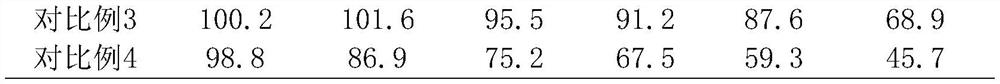

[0035] Example 3 Silicone composition for violet LED encapsulation

[0036] A silicone composition for encapsulation of purple light LEDs, including components A and B of equal mass; component A includes the following raw materials in parts by mass: 100 parts by mass of phenylvinyl silicone resin, 0.15 parts of platinum series catalyst, and 2 parts by mass of tackifier parts, 1 part of antioxidant; the B component includes the following raw materials in parts by mass: 60 parts of phenylvinyl silicone resin, 45 parts of crosslinking agent, 0.04 part of inhibitor, and 1.8 parts of ultraviolet absorber. The vinyl content of phenylvinyl silicone resin is 4%, the viscosity is 12000mPa s, the refractive index is 1.54, the platinum series catalyst is chloroplatinic acid-tetramethyldivinyldisiloxane complex, and the content of platinum is 5000ppm, the antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, and the tackifier is γ-methacryloxypropyl trimethoxy base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com