Excavator quick replacement connector

A conversion joint and quick conversion technology, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of high cost of hydraulic joints, consume a lot of physical strength, and long operation time, so as to achieve low production costs, improve work efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

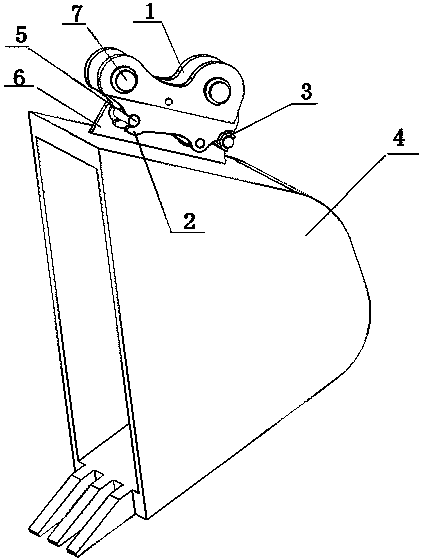

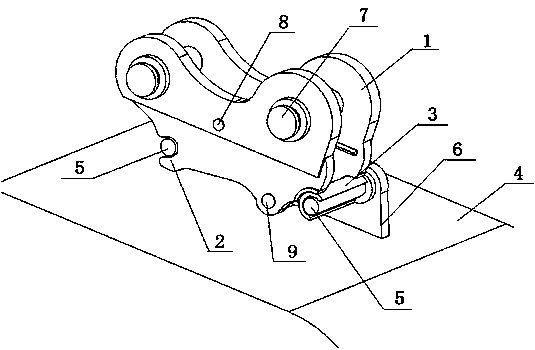

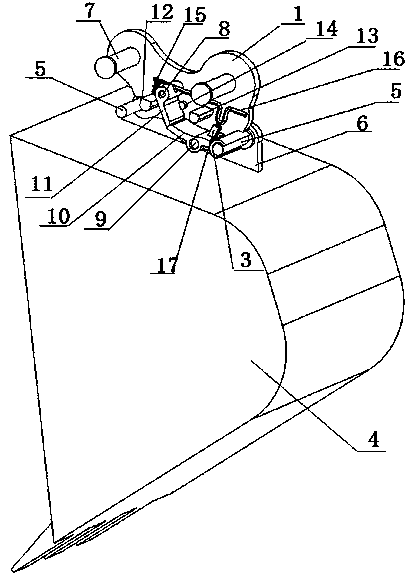

[0042] like Figure 1-19 As shown, a quick adapter for an excavator includes an adapter frame body 1, a fixed hook and a movable hook. The top of the adapter frame body 1 is provided with an arm mounting hole 21 for assembling with the arm of the excavator. The adapter frame body 1 The bottom is provided with two left and right hooks, the left hook 2 is a fixed hook, the right hook 3 is a movable hook, and the conversion adapter frame body 1 clamps the bucket installation shaft 4 of the bucket connection seat 6 through the fixed hook and the movable hook. The movable hook mentioned above is fixed by a locking device;

[0043] The adapter frame body 1 is composed of the front and rear side panels, the middle rotating shaft 8, the lower rotating shaft 9, the left connecting column 12 of the frame body, the right connecting column 13 of the frame body and the baffle plate 14, and the front and rear side panels pass through the frame body The left connecting column 12 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com