Erecting structure of variable cross-section beam-column-free cap

A beamless column and variable cross-section technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of waste of raw materials for formwork erection, poor molding quality, economic loss, etc., and achieve saving of erection building materials, easy control of the slope angle, and guarantee The effect of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

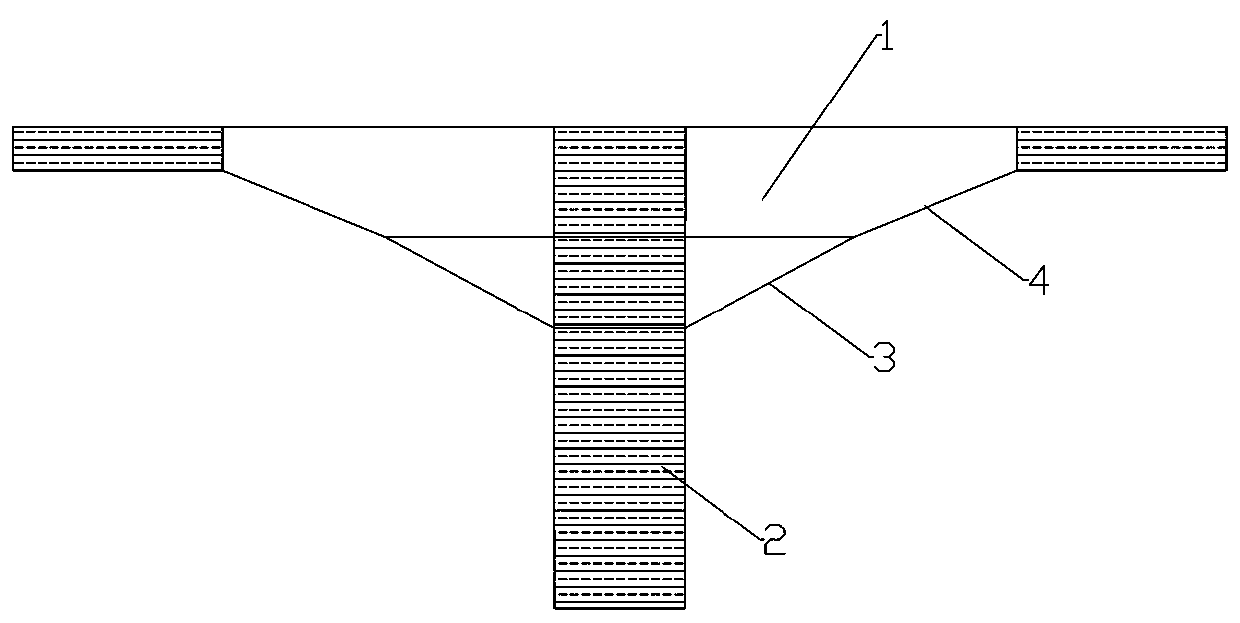

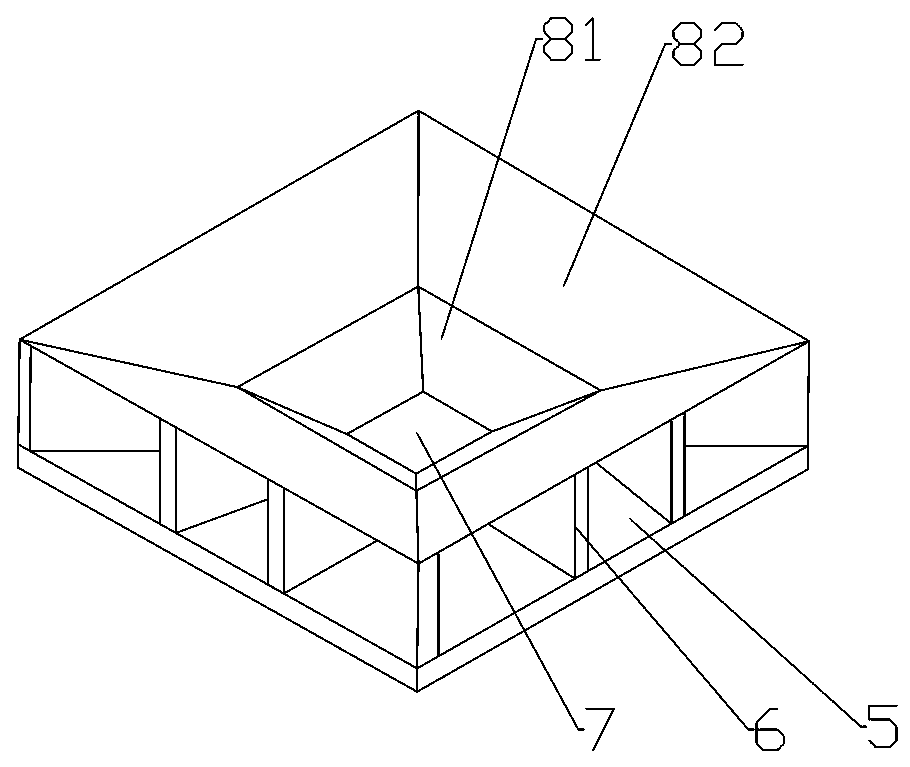

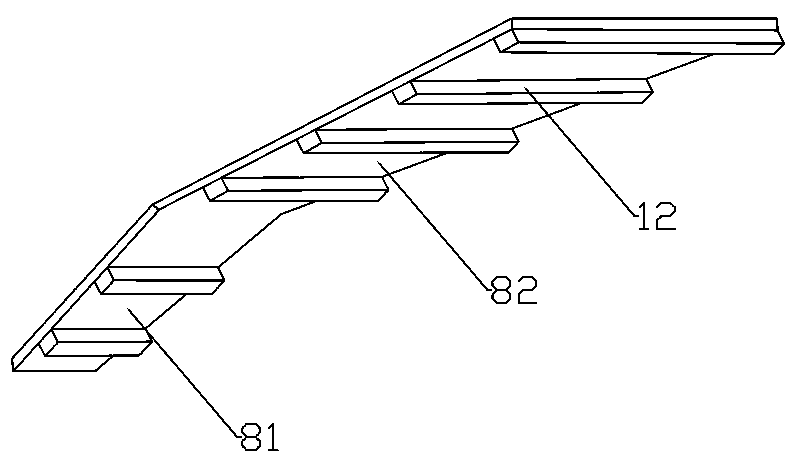

[0021] Embodiment 1: A kind of beamless column cap with variable cross-section, such as figure 1 As shown, the column cap body 1 is included, the interior of the column cap body is hollow, the upper end of the support column 2 runs through the column cap body 1, the column cap body 1 and the support column 2 are jointly connected with the floor, and then jointly support the floor. The column cap body 1 is an inverted cone, and the outer wall of the column cap body 1 is composed of two ring walls with different inclination angles, that is, the outer wall of the column cap body includes a first ring wall 3 and a second ring wall 4 with different inclinations, And the first ring wall 3 is connected to the end of the second ring wall 4, wherein the inclination angle of the first ring wall 3 is greater than the inclination angle of the second ring wall 4, so that the column cap body 1 is a beamless column with variable cross-section cap. Wherein the inclination angle of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com