Microchannel heat exchange device based on hollow foam materials and application of microchannel heat exchange device

A technology of heat exchange devices and foam materials, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of low effective heat exchange area, poor corrosion resistance, complicated preparation process, etc., and increase the contact area of heat exchange , a wide range of types, high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application specific Embodiment approach

[0046] In the specific implementation of the microchannel heat exchange device based on hollow foam material and its application, the present invention uses hollow foam materials with different physical / chemical structures and different materials as the materials for the main functional area of heat exchange, and adopts different configurations The fluid inlet port, collecting cavity, fluid-tight barrier layer, hollow foam material microchannel tube wall heat exchange area, design the heat exchange unit assembly of the microchannel heat exchange device based on hollow foam material according to the present invention, and enumerate The specific implementation of the corresponding application is as follows:

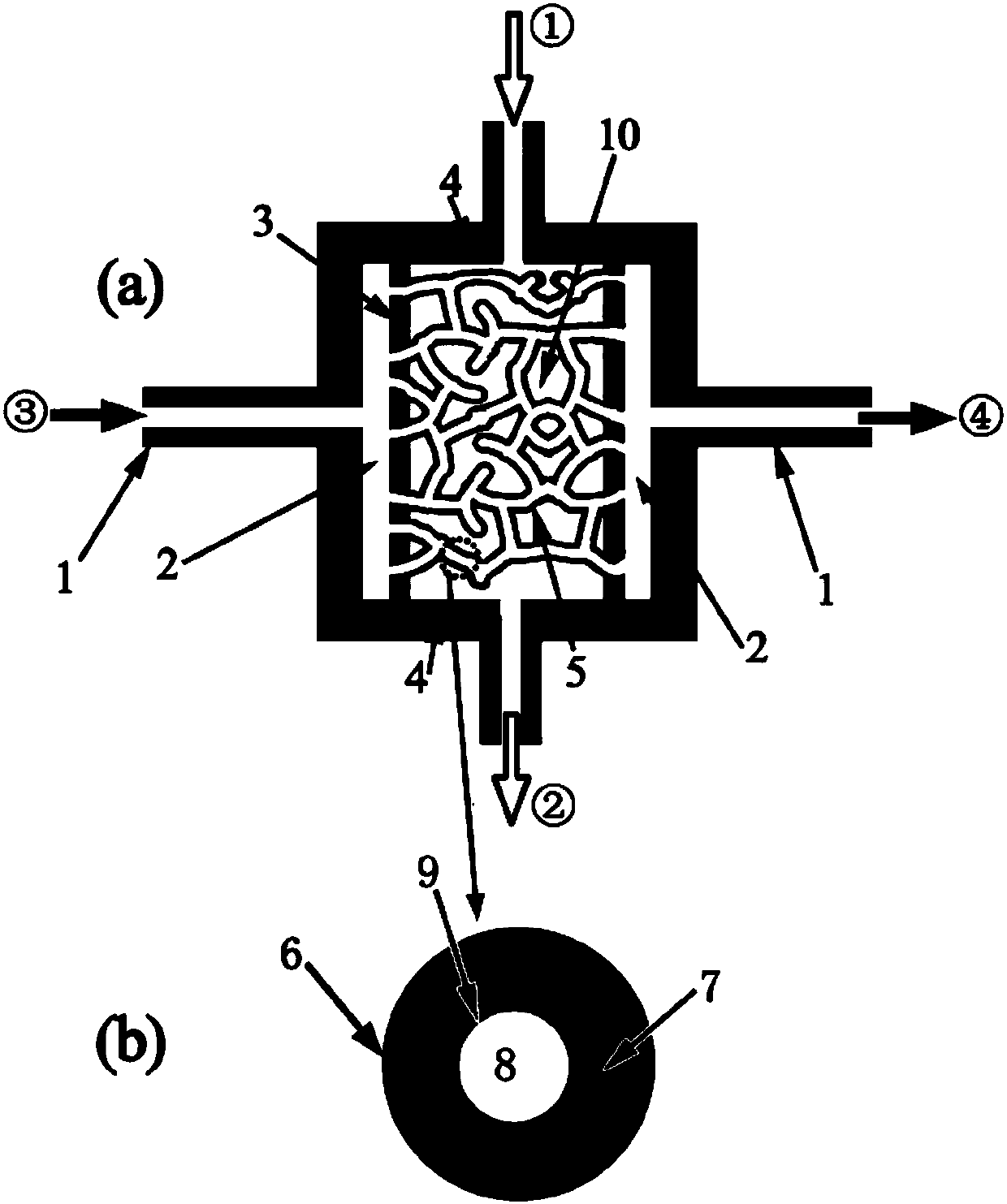

[0047] like figure 1 As shown, from the macroscopic appearance, the microchannel heat exchange device uses the hollow foam material with dense microchannel tube wall as the main functional area constituent material, and the hollow foam material as the main core functional...

Embodiment 1

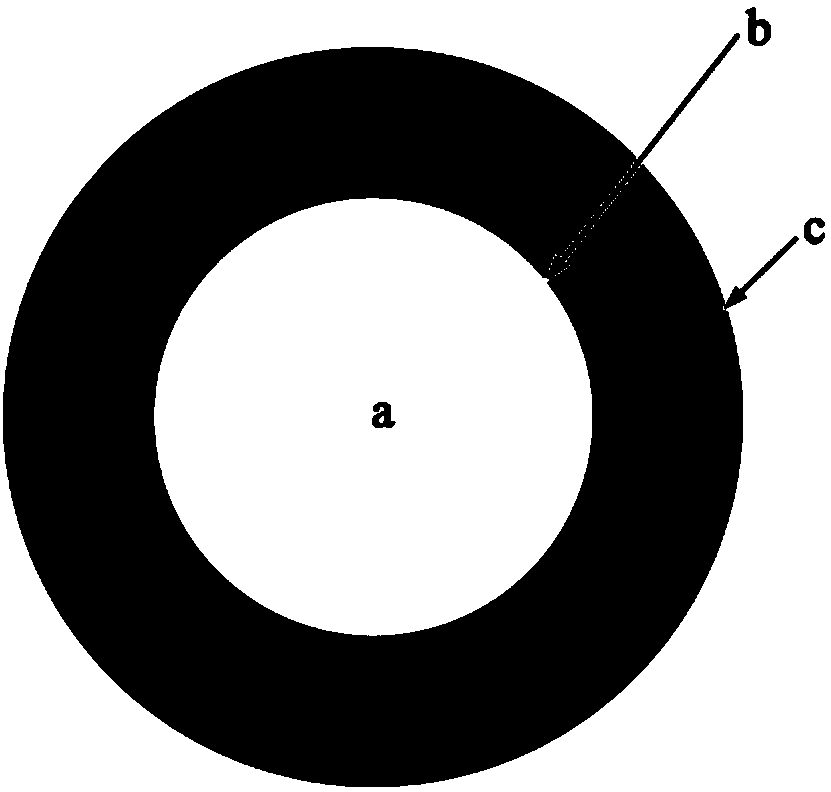

[0063] This embodiment adopts the structural design of the cylindrical heat exchange unit assembly, see the attached Figure 10 . The main heat exchange functional area consists of image 3 The shown physical structure or chemical structure is composed of hollow foam material with isotropic hollow microchannel pipe wall, and the macroscopic dimension of the hollow foam material cylinder is φ300mm, and the height is 600mm. Wherein, a is the cavity of the hollow microchannel; b is the surface of the inner wall of the hollow microchannel; c is the surface of the outer wall of the hollow microchannel. The wall body of the hollow microchannel is made of stainless steel, the outer diameter of the hollow microchannel is 2mm, and the inner diameter is 1mm. The microchannel heat exchange device composed of the heat exchange unit components is used for the condensation of water vapor, the water vapor inlet temperature is 105°C, the water vapor flows in the macroscopic three-dimensiona...

Embodiment 2

[0065] This embodiment adopts the structural design of the cylindrical heat exchange unit assembly, see the attached Figure 10 . The main heat exchange functional area is composed of a hollow foam material, and the structure of the hollow microchannel tube wall of the hollow foam material is as follows: Figure 4 shown. The macroscopic dimensions of the hollow foam cylinder are φ200mm and 400mm high. Wherein, a is the inner cavity of the hollow microchannel; b is the inner wall surface of the hollow microchannel; c is the outer wall surface of the hollow microchannel whose heat exchange area is further increased after surface treatment. The wall body of the hollow microchannel is made of pure copper, and the outer wall surface has a rough surface structure after surface treatment. The rough surface is made of pure copper particles with a particle size of 0.2 mm and sintered by powder. The hollow microchannel has an outer diameter of 3 mm and an inner diameter of 1.5 mm. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Inner diameter size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com