Surface roughness monitoring model based on data mining and construction method

A technology of surface roughness and data mining, which is applied in the fields of information retrieval and database structure, can solve problems such as the influence of the processing site, the inability to be widely used in workshops and factories, and the complex causes of surface roughness, so as to improve the accuracy and intelligent level, and realize The effect of online real-time prediction and reduction of blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

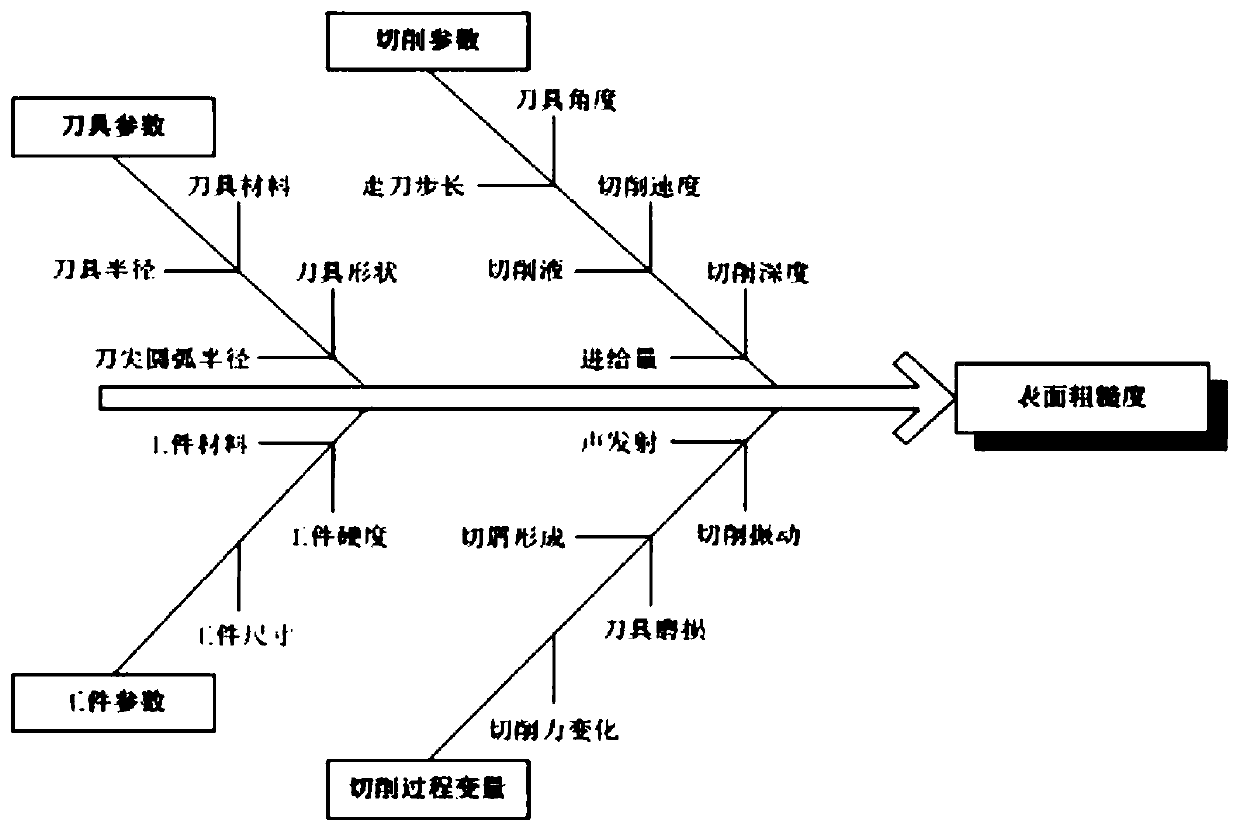

[0062] The present invention applies multi-sensor technology to the research of the surface quality of machining, and studies the surface roughness prediction method based on singular spectrum analysis and multi-feature fusion by collecting cutting force and vibration information during milling of difficult-to-machine materials, so as to realize effective milling surface quality The prediction also provides the basic data source and the prediction function module for the cutting database.

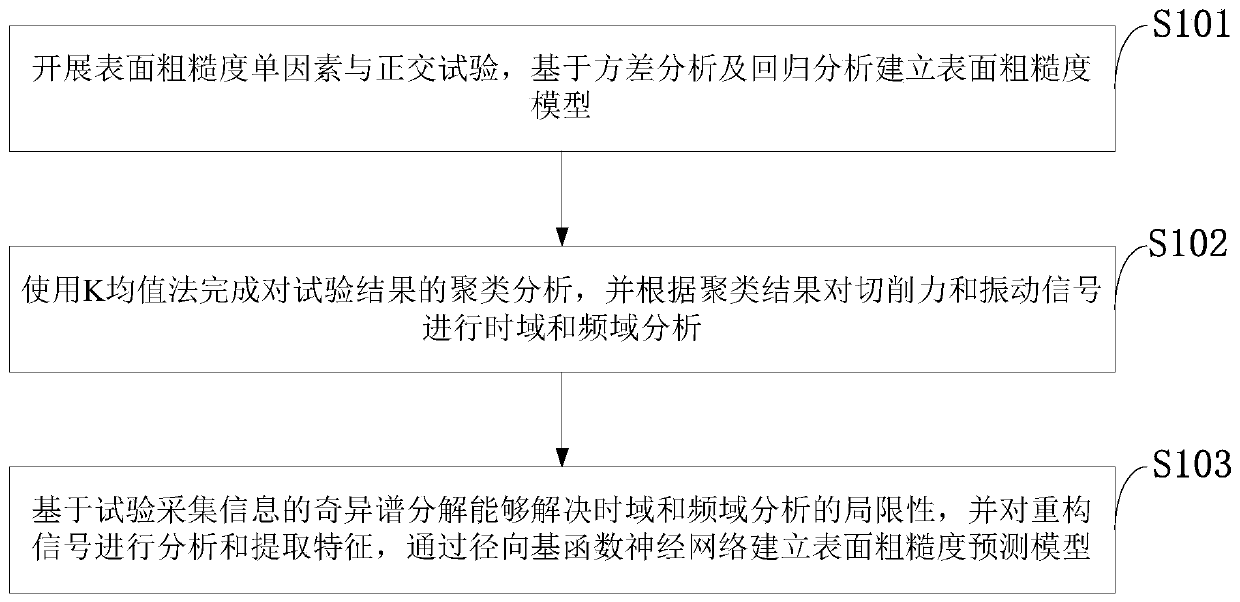

[0063] Such as figure 1 As shown, the construction method of the surface roughness monitoring model based on data mining provided by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com